Efficient lost-wax composite coating

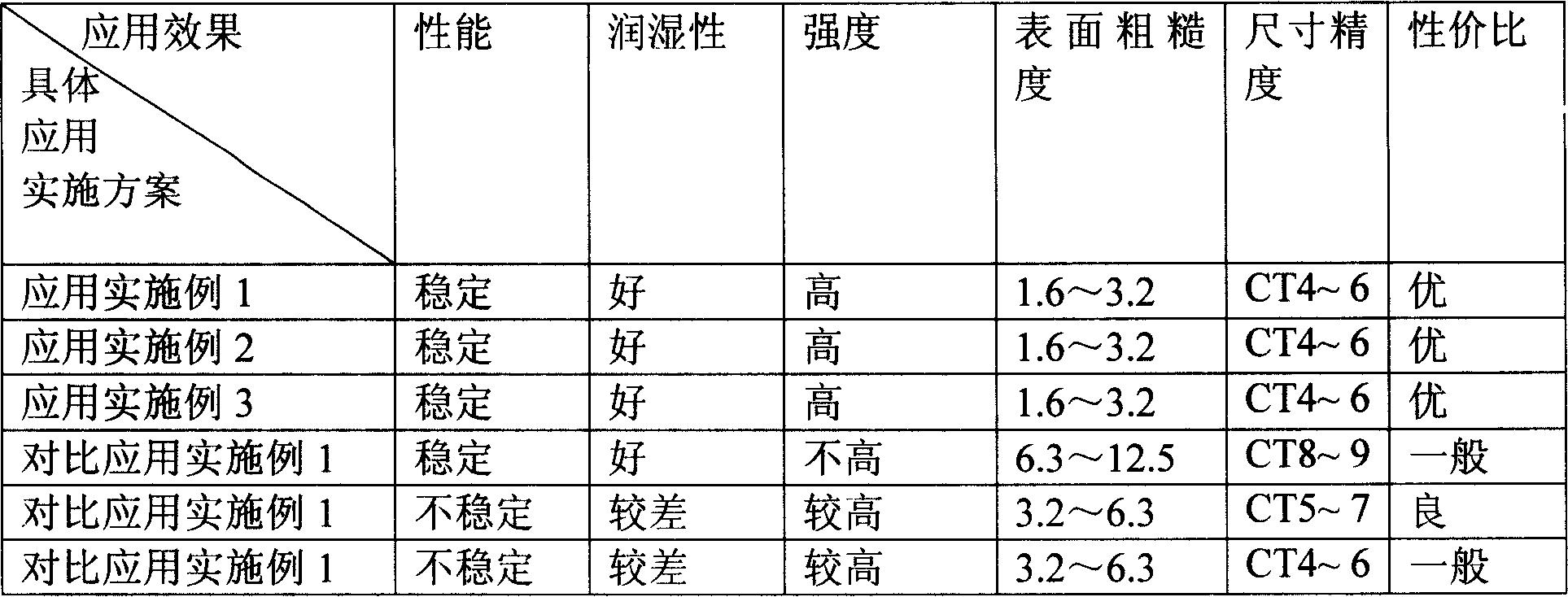

A composite coating and investment technology, which is applied to casting molding equipment, coatings, casting molds, etc., can solve the problems of poor performance stability of castings, low high-temperature strength of mold shells, and many layers of mold shells, and achieve low production costs. , small surface roughness and low price

Inactive Publication Date: 2007-01-17

李士良

View PDF1 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] The present invention mainly aims at the high surface roughness, low dimensional accuracy, low high-temperature strength of the molded shell, many layers of the molded shell, poor performance stability of the casting, slow drying, and long shell-making cycle in the castings obtained in the pr

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

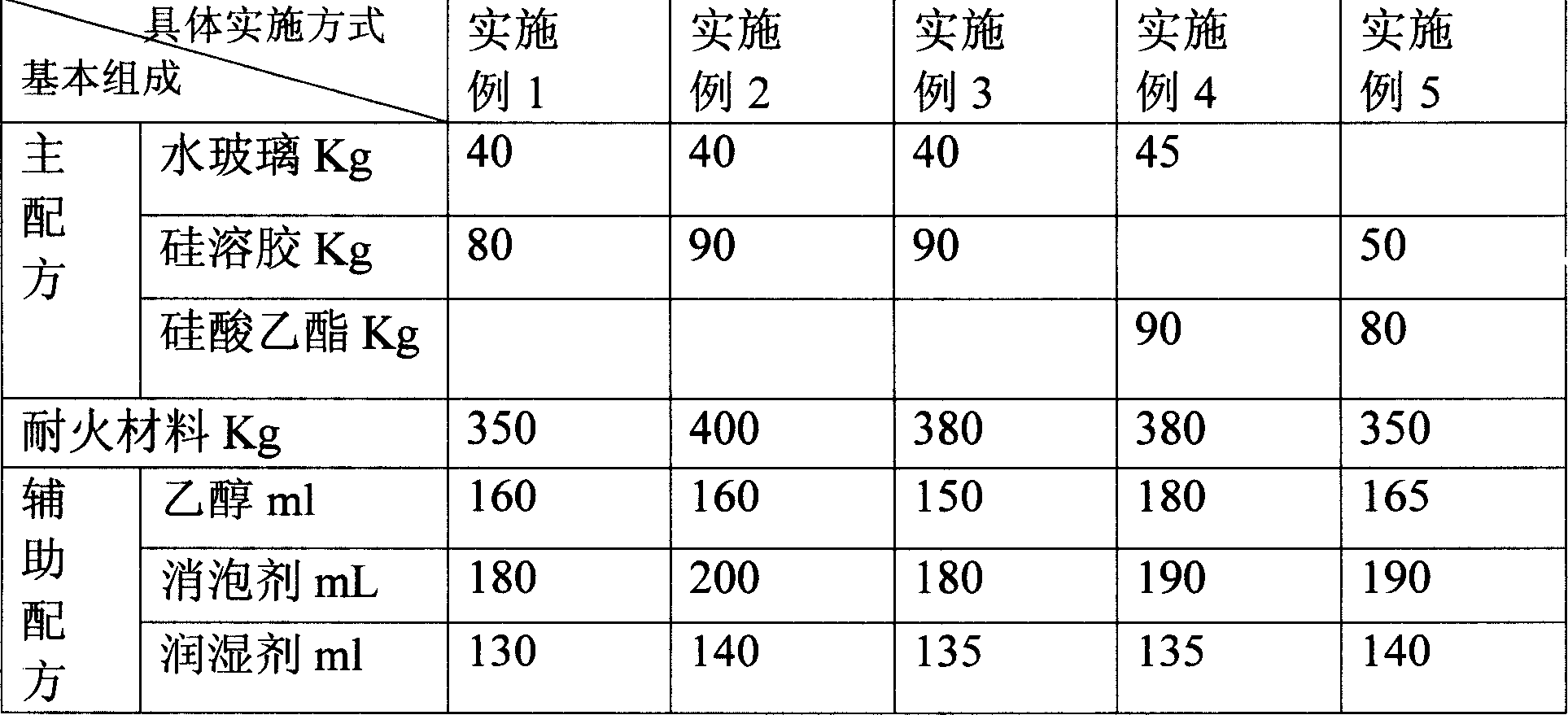

An efficient composite paint for the investment casting contains primary component (20-28 Wt%) prepared from two or more of water glass, silicon sol and ethyl silicate, refractory powder (70-76) and secondary component (1-5). Its advantages are high stability, high hardening speed, high wettability and high high-temp strength.

Description

technical field [0001] The invention relates to a coating, in particular to a composite coating made by mixing water glass, silica sol and ethyl silicate as the main raw material and other auxiliary agents; it belongs to the field of metal casting. Background technique [0002] Investment casting, also known as "lost wax casting", is an ancient casting method. The earliest investment casting found in my country was the early Warring States period more than 2,400 years ago, starting from the 1950s; investment casting was used in industrial production, after more than 40 years of development; investment casting has become the basic process in my country's machinery manufacturing industry , and form a unique industry. Investment casting of carbon steel mechanical parts is the main body of investment casting production in my country. The annual output of investment castings is about 150,000 tons, accounting for about 95% of the total output of investment castings. The production...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B22C3/00B22C7/02B22C9/04

Inventor 李士良陈吉华

Owner 李士良

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com