Dust collector of fixed type cutting machine

A technology of dust collection device and cutting machine, which is applied to the attachment device of sawing machine, swirl device, and the device whose axial direction of swirl flow can be reversed, etc., which can solve the problem of reduced dust collection efficiency and difficulty in handling dust collectors, etc. problem, to achieve the effect of preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

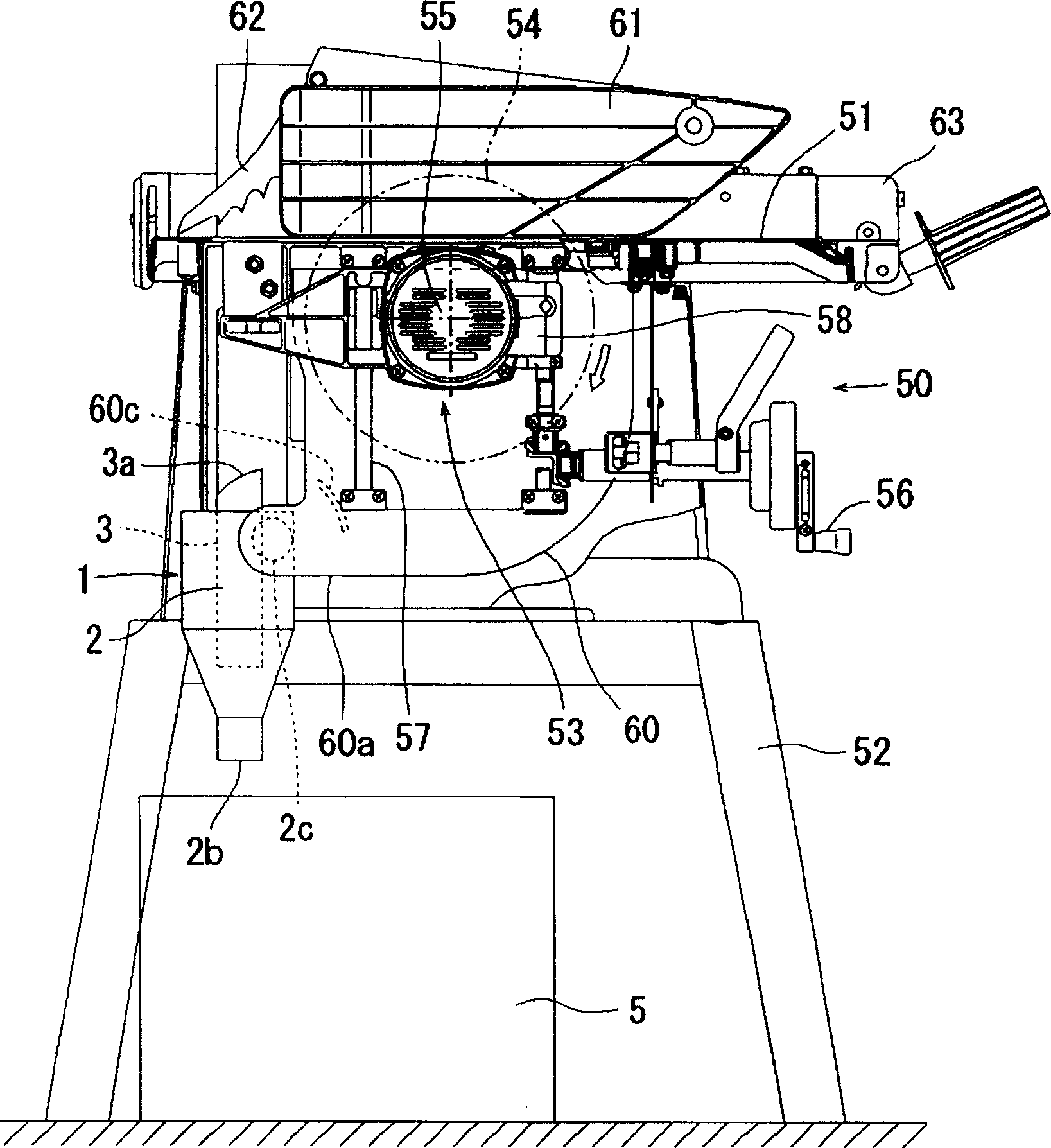

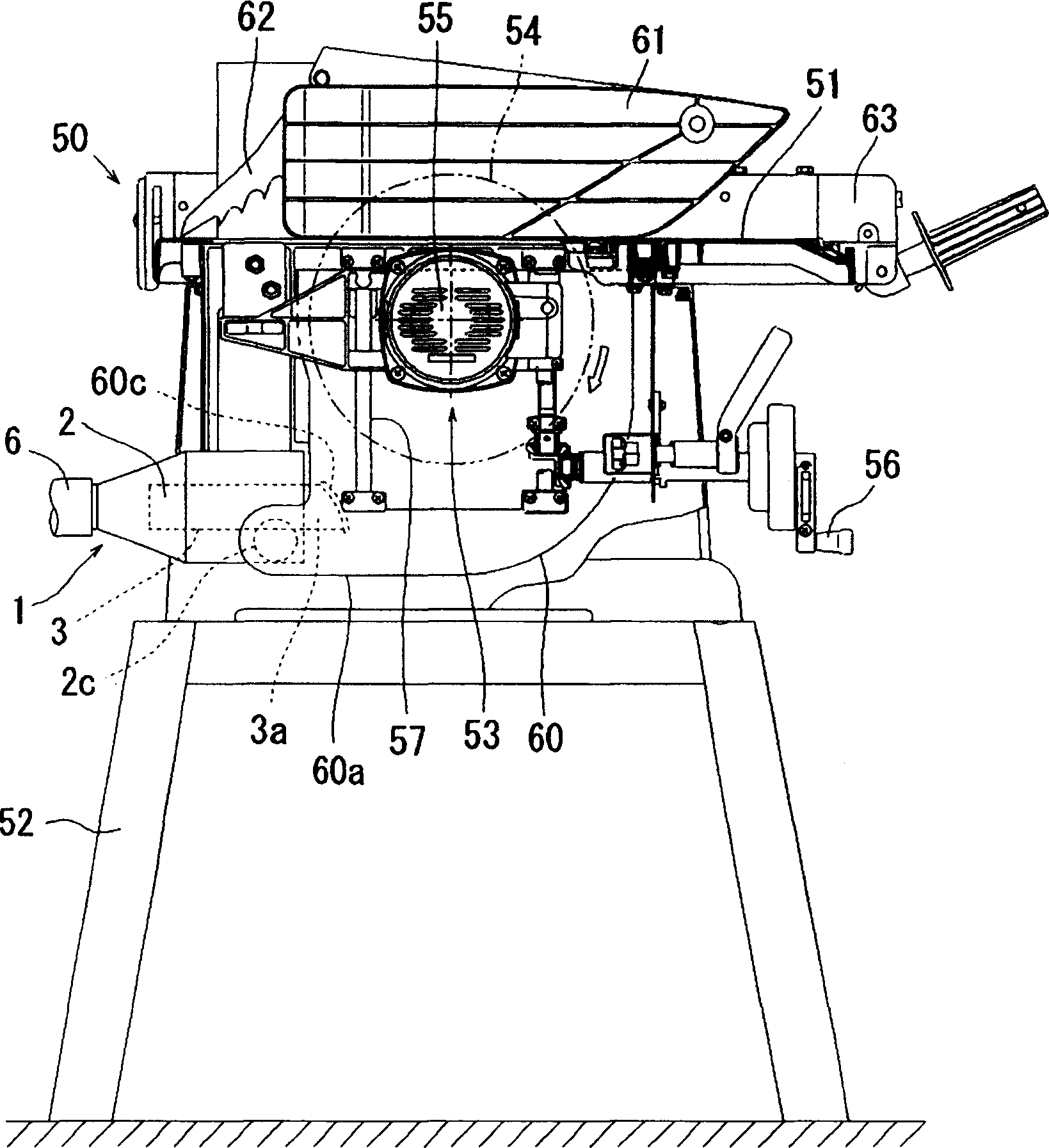

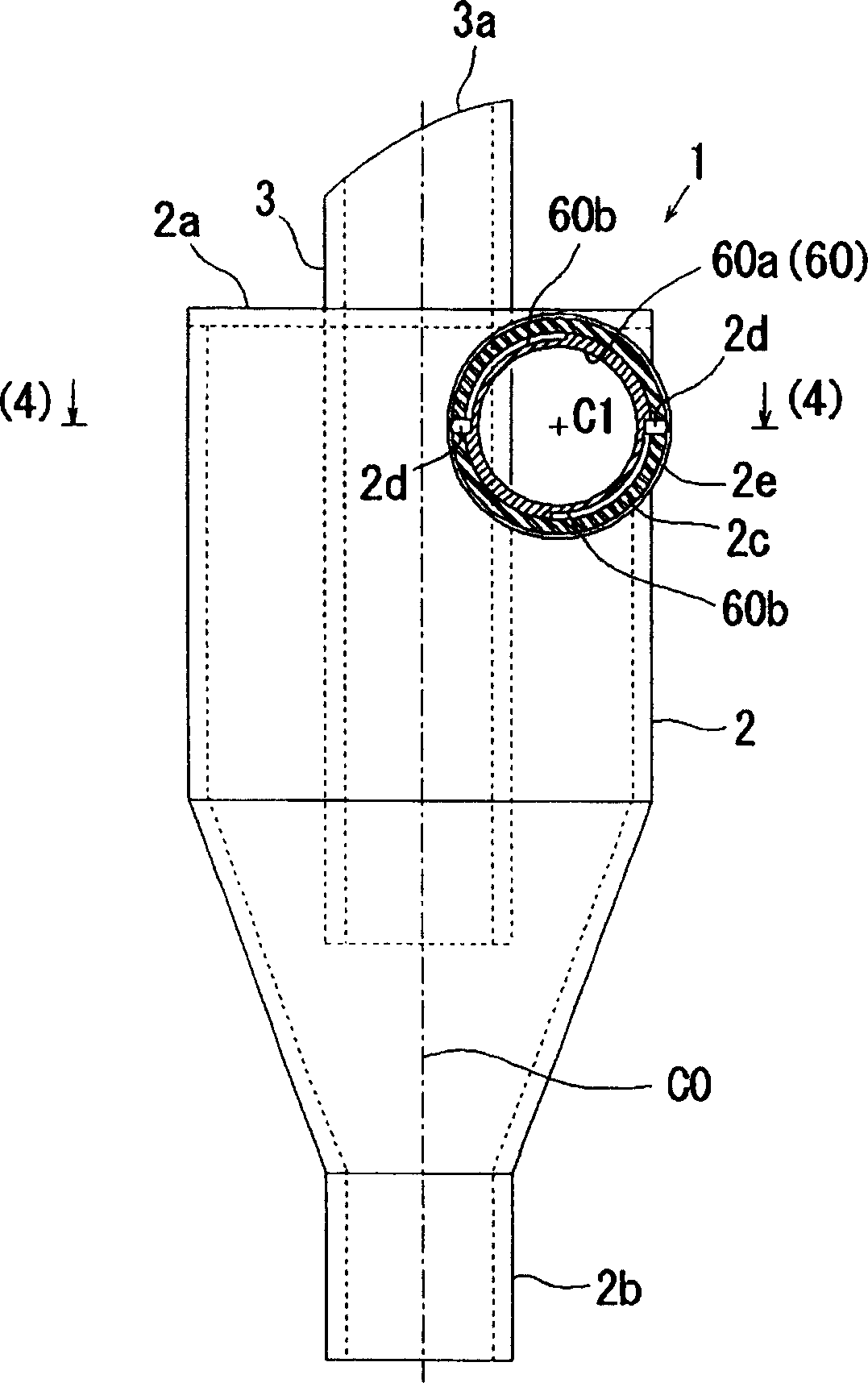

[0030] Below, based on Figure 1 to Figure 6 Embodiments of the present invention will be described. figure 1 The cutter 50 provided with the dust collector 1 of this embodiment is shown. The cutting machine 50 is a so-called fixed circular saw called a table saw, and includes: a workbench 51 on which cutting materials are placed (omitted in the figure); a stand 52 that supports the workbench 51 horizontally; The main body 53 is arranged on the upper part of the platform 52 and on the lower side of the workbench 51 .

[0031] The cutter main body 53 has circular saw teeth 54 and a motor 55 for rotating them. Such as figure 1 As shown by the hollow arrow, the sawtooth 54 rotates clockwise. Furthermore, in figure 1 In , the cut material is cut by moving from right to left.

[0032] The motor 55 is attached to a base 58 which can move vertically and parallelly via support columns 57 to 57 provided on the stand 52 .

[0033] The upper part of the sawtooth 54 protrudes upwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com