High-temperature superconductive power cable terminal

A power cable and high-temperature superconducting technology, which is applied to cable terminals, superconducting devices, superconducting/high-conducting conductors, etc., can solve problems such as inability to transport low-temperature liquids, inability to apply high-temperature superconducting cables, and inability to keep heat. Safety guarantee, simple and reliable insulation processing, and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

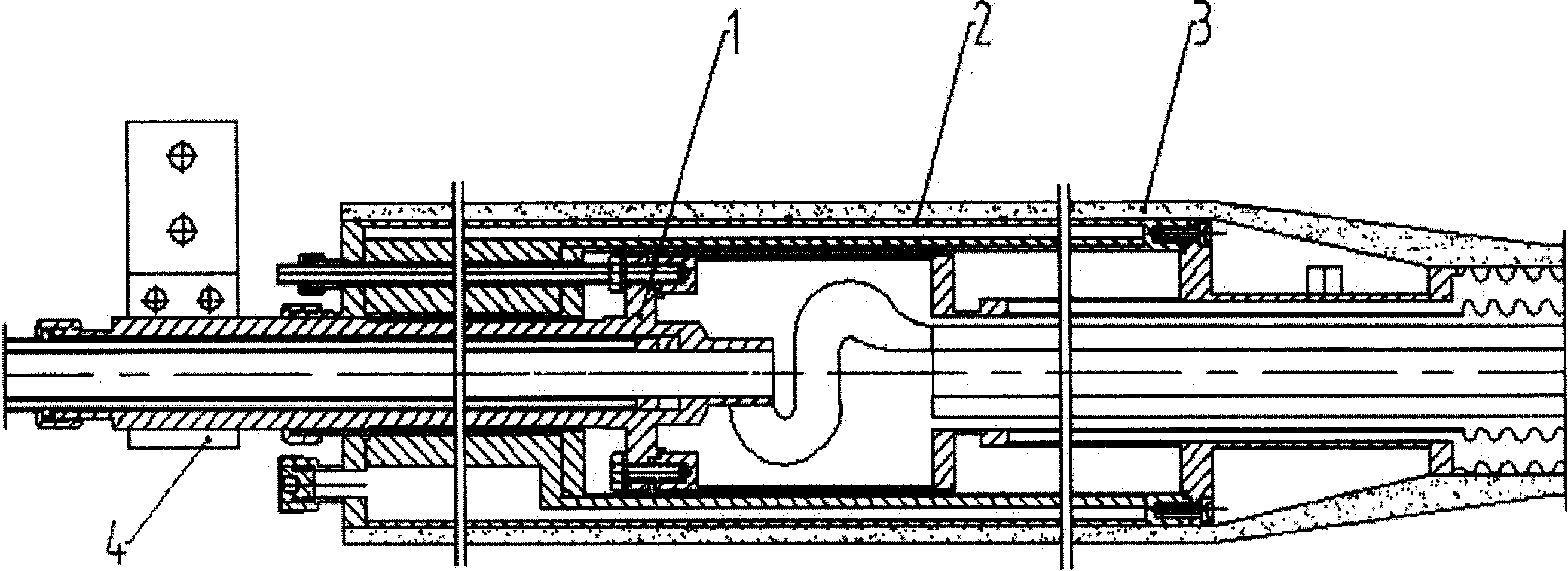

[0025] figure 1 Shown is the schematic structural diagram of the terminal of the present invention, which is composed of terminal internal parts 1, terminal insulation cover 2, insulating layer 3 and connection terminal 4. The terminal inner part 1, the terminal insulation cover 2 and the insulating layer 3 are coaxially placed sequentially from the inside to the outside. The terminal inner part 1 is located on its central axis, followed by the insulation cover 2, and the outermost layer is the insulating layer 3. The connection terminal 4 is fixed on the outer end of the terminal inner part 1 .

[0026] The function of the terminal internal part 1 is to output a large current, connect electrical measurement signals, and input liquid nitrogen for cooling superconducting cables. The function of the insulation cover 2 is to prevent the ambient temperature from being transmitted to the superconducting cable in the terminal, so as to realize the requirement of low-loss operation....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com