Core piece for exhaust gas catalyst device, method of producing the same, and method of installing and fixing the same

A technology of catalyst device and fixing method, which is applied in the direction of exhaust device, catalyst carrier, chemical instrument and method, etc., can solve the problems of increased weight, increased number of processes, increased cost of exhaust catalyst device 1', etc., and achieves processing cost Reduce and realize the effect of manufacturing process and enrich deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

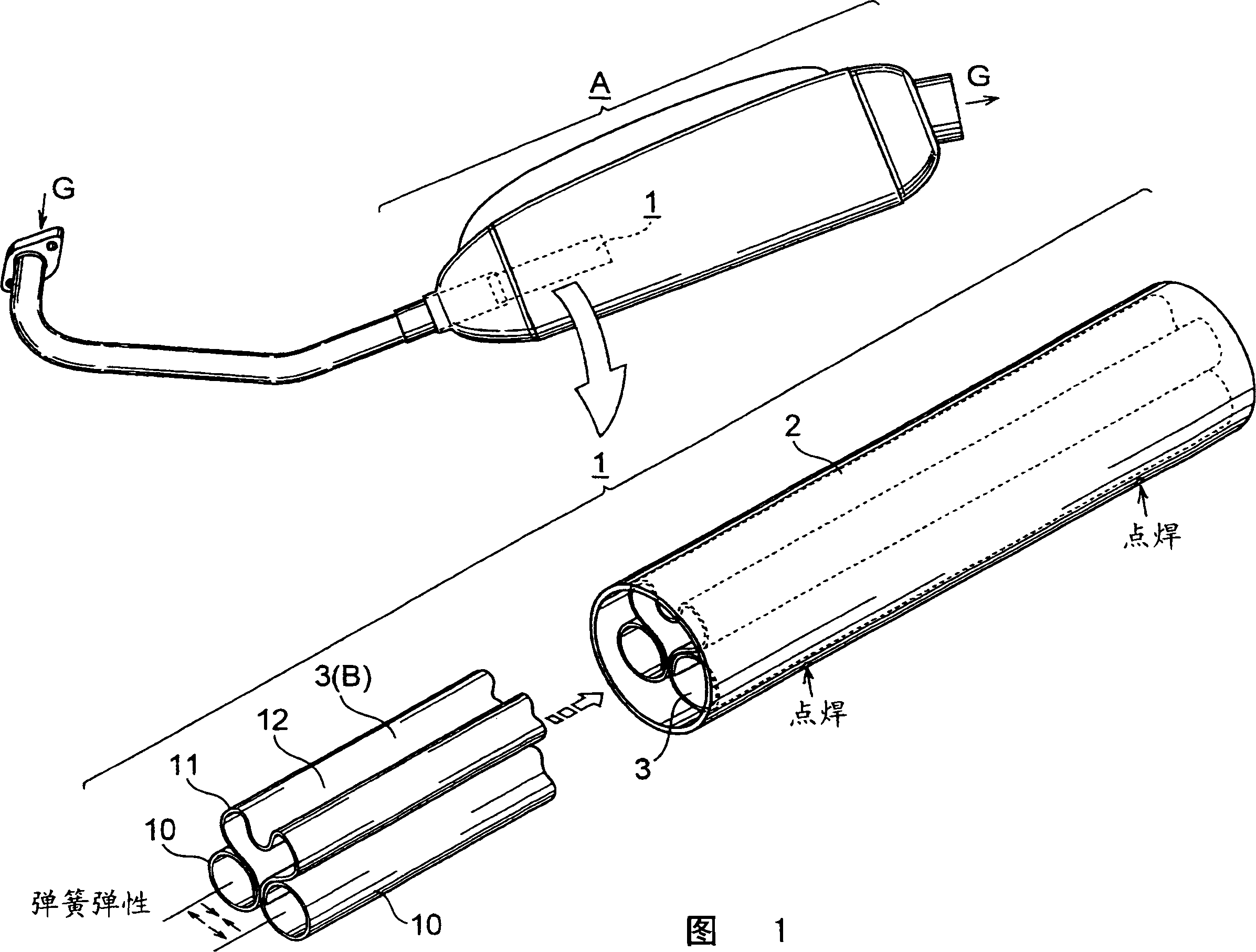

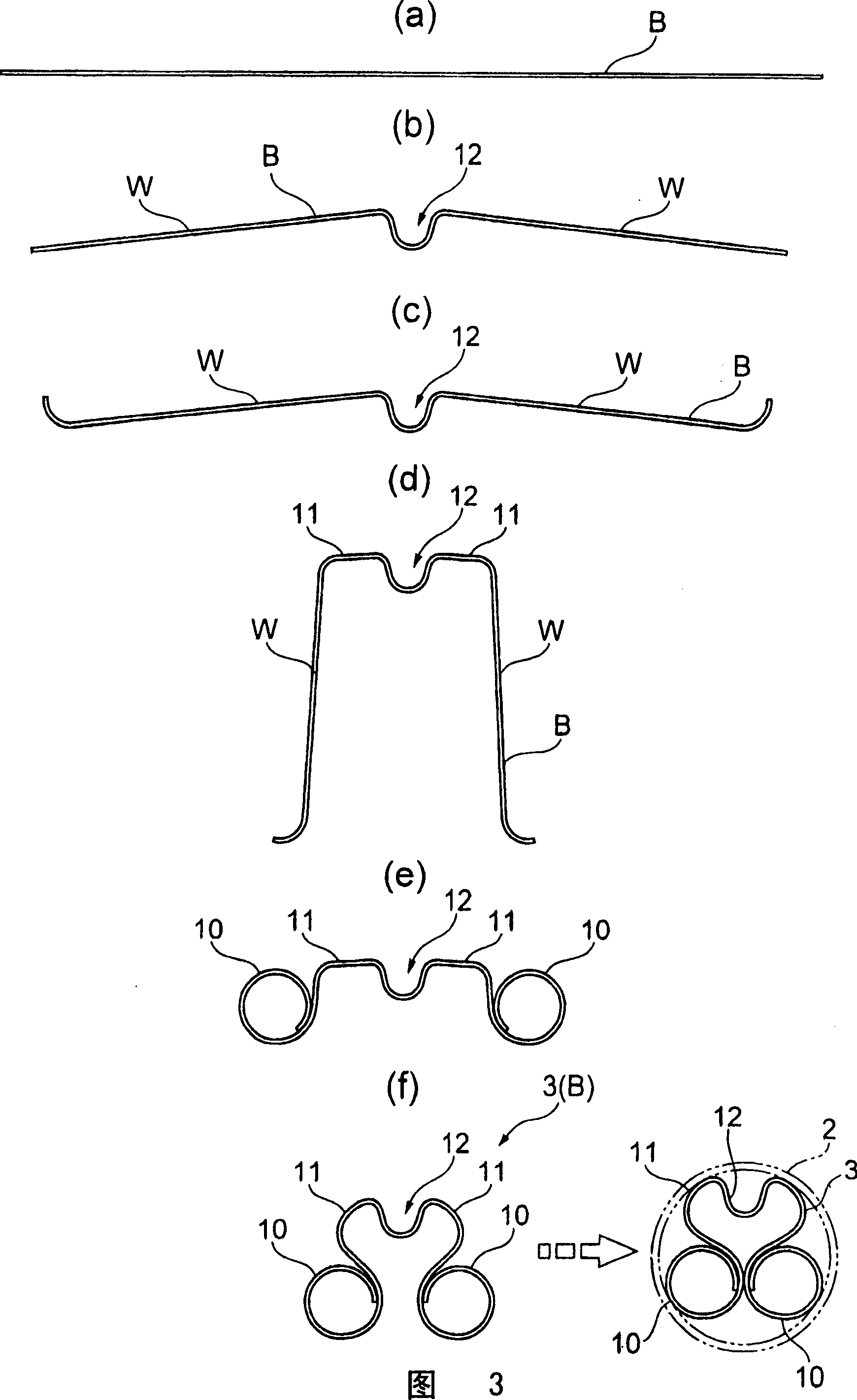

[0064] Embodiment 1 is an example in which the spring elasticity of the core 3 is used to realize the inserting and fixing of the core 3 as described above. When a deformation occurs, the deformation is restored to the outside. In other words, it is a cross-sectional shape that has a spring action that restores the pressing deformation generated inward to the outside. Therefore, the core 3 uses the cross-sectional shape of the component itself to achieve elastic installation to the outer cylinder 2, so as to be inserted into the outer cylinder 2 The status of is fixed (insert fixed).

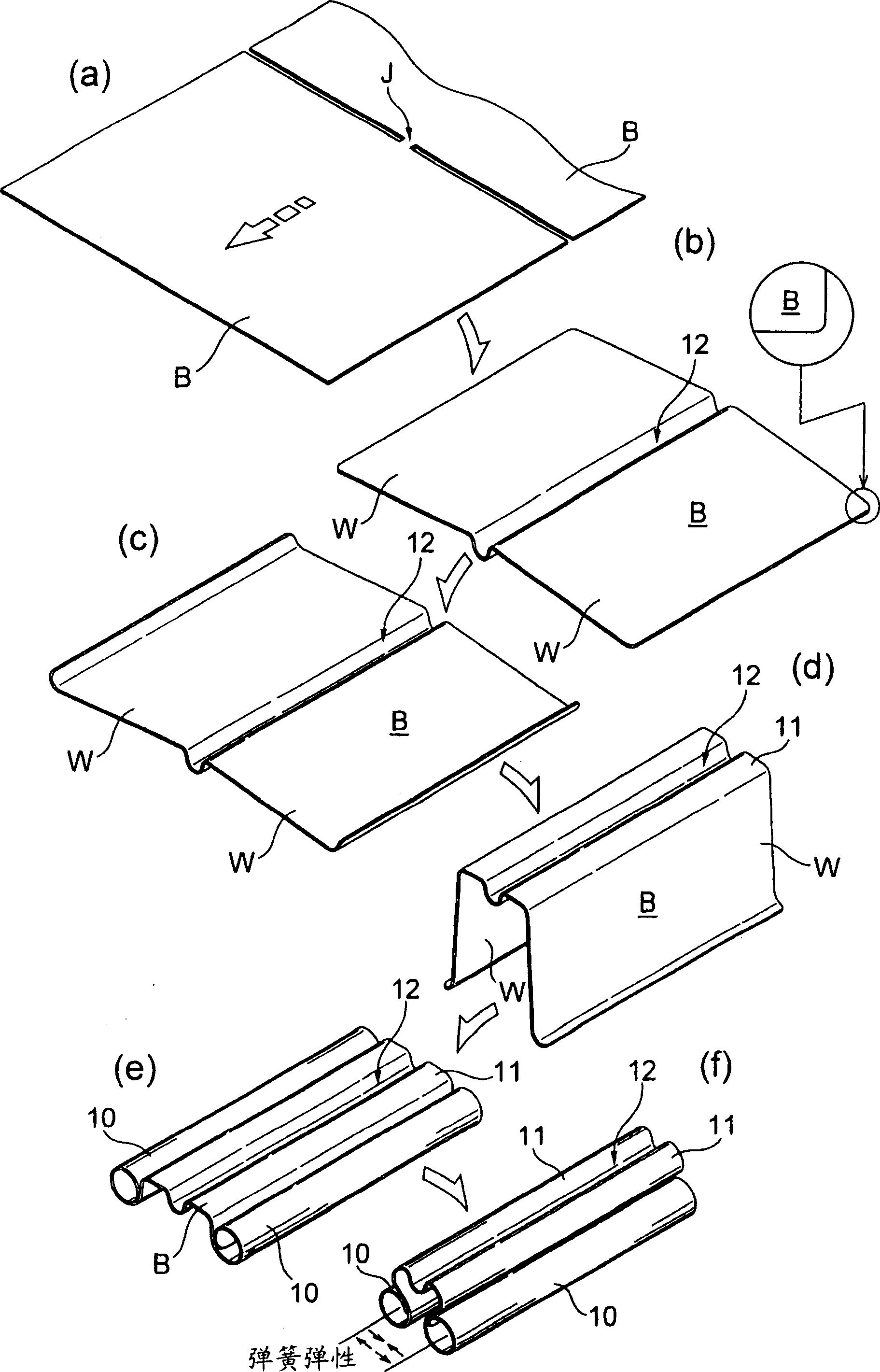

[0065] Furthermore, in the present embodiment, the core member 3 having such a spring action is formed by appropriately bending a single sheet metal material (referred to as mother plate material B). Specifically, the two ends of the motherboard material B are rounded into a circle so that the two ends can be elastically opened and closed (expanded), and the core member 3 is clamped by utilizin...

Embodiment 2

[0096] Embodiment 2 is an example in which the inserting and fixing of the core member 3 is realized based on the diameter reducing process (caulking process) performed on the outer cylindrical body 2 . As an example, caulking is carried out as shown in FIG. 8 by narrowing both ends of the opening of the outer cylindrical body 2 and the cylindrical portion (referred to here as a substantially central portion) over the entire circumference.

[0097] At this time, the caulking process of reducing the diameter of the opening ends of the outer cylinder 2 inwardly is performed only on the part of the outer cylinder 2 where the core 3 does not exist, and the deformation of the opening ends is utilized to seal from the left and right sides. The position (movement) of the core 3 is restricted, and the core 3 is fastened in the outer cylindrical body 2 . On the other hand, the caulking process of reducing the diameter of the cylindrical portion of the outer cylinder 2 inward is perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com