Method for preparing high purity alpha corn protein

A high-purity technology of corn protein, applied in the field of development and utilization of plant protein, to achieve a wide range of utility and functional effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

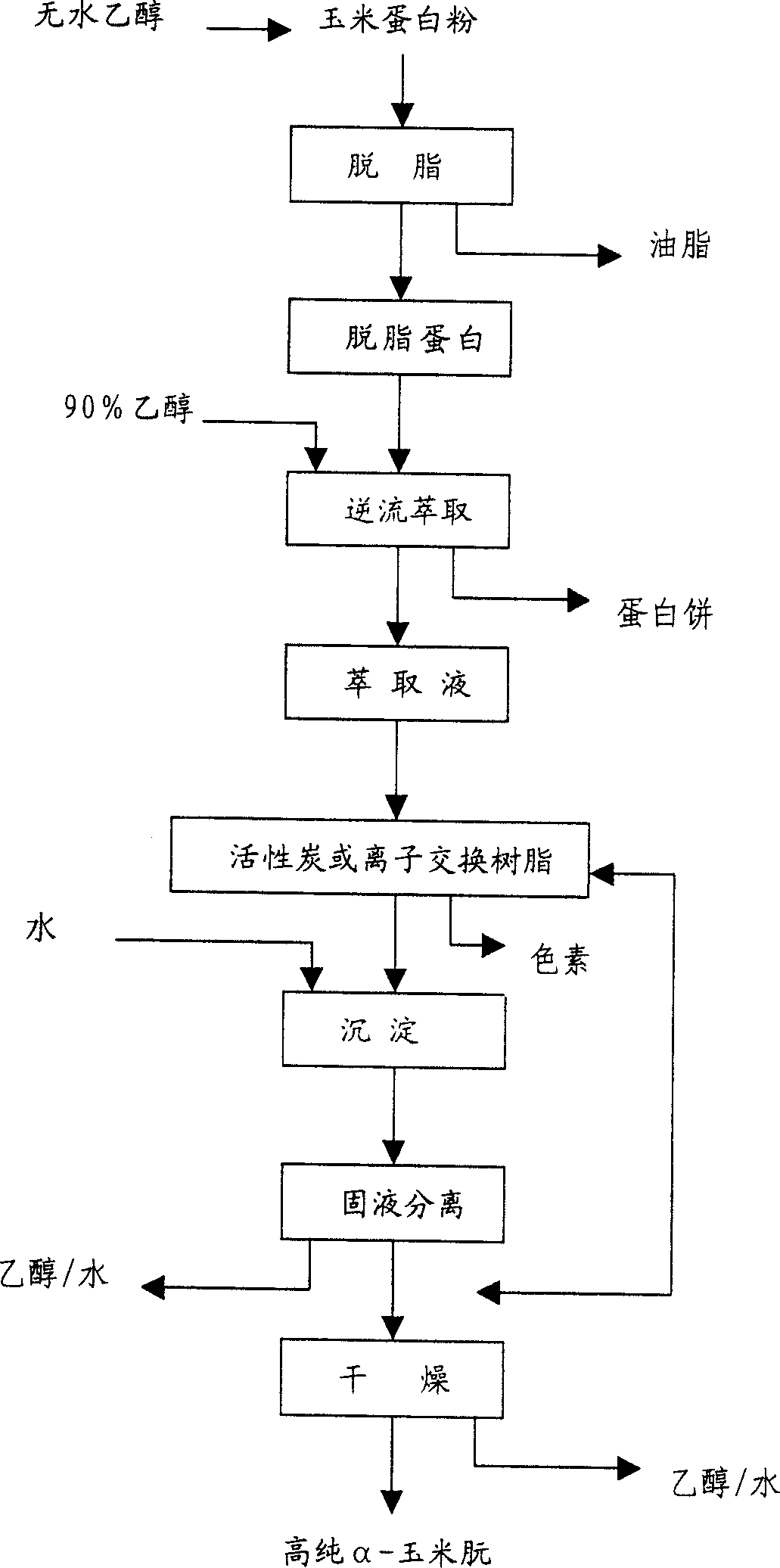

Image

Examples

Embodiment 1

[0021] 100g corn gluten powder (water content 5%) was granulated, then added 5 times the volume of absolute ethanol, defatted twice; defatted corn gluten granules were added 6 times the volume of 80% ethanol, leached in countercurrent at room temperature for 24 hours, and solid-liquid separation; Add 2 times the volume of 0.25% NaCl aqueous solution to the filtrate, and wash the obtained precipitate with water three times repeatedly to remove the NaCl therein. Carry out vacuum drying then and make yellow zein 28g.

Embodiment 2

[0023] 100g corn gluten powder (water content 5%) was granulated, then added 5 times the volume of absolute ethanol, defatted twice; defatted corn gluten granules were added 6 times the volume of 80% ethanol, leached in countercurrent at room temperature for 24 hours, and solid-liquid separation; Adjust the pH of the filtrate to 5.5, add 10% activated carbon powder, and stir at 30°C for 5 hours; use high-speed centrifugation for solid-liquid separation of the decolorization solution; concentrate the filtrate to 1 / 2 volume under reduced pressure, recover ethanol, and then vacuum Dry to obtain 25g of white corn protein.

Embodiment 3

[0025] 100g of corn gluten powder (water content 5%) was granulated, then added 7 times the volume of absolute ethanol, defatted twice; defatted corn gluten granules were added with 10 times the volume of 90% ethanol, leached in countercurrent at room temperature for 12 hours, and separated into solid and liquid; Adjust the pH of the filtrate to 6.5, add 6% activated carbon powder, and stir at 60°C for 2 hours; the decolorization solution is separated from solid and liquid by vacuum filtration; 3 times the volume of 1% NaCl aqueous solution is added to the filtrate, and the obtained precipitate is washed repeatedly with water for 3 Once, the NaCl therein was removed completely; then vacuum drying was carried out to obtain 27g of white α-zein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com