Rubber powder plasticizing device

A rubber powder and slow cooling technology, applied in the field of processing machinery, can solve the problems of slow cooling, reduction of unit output of equipment, matching of production capacity, etc., to achieve the effect of accelerating temperature rise rate, increasing unit output and increasing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

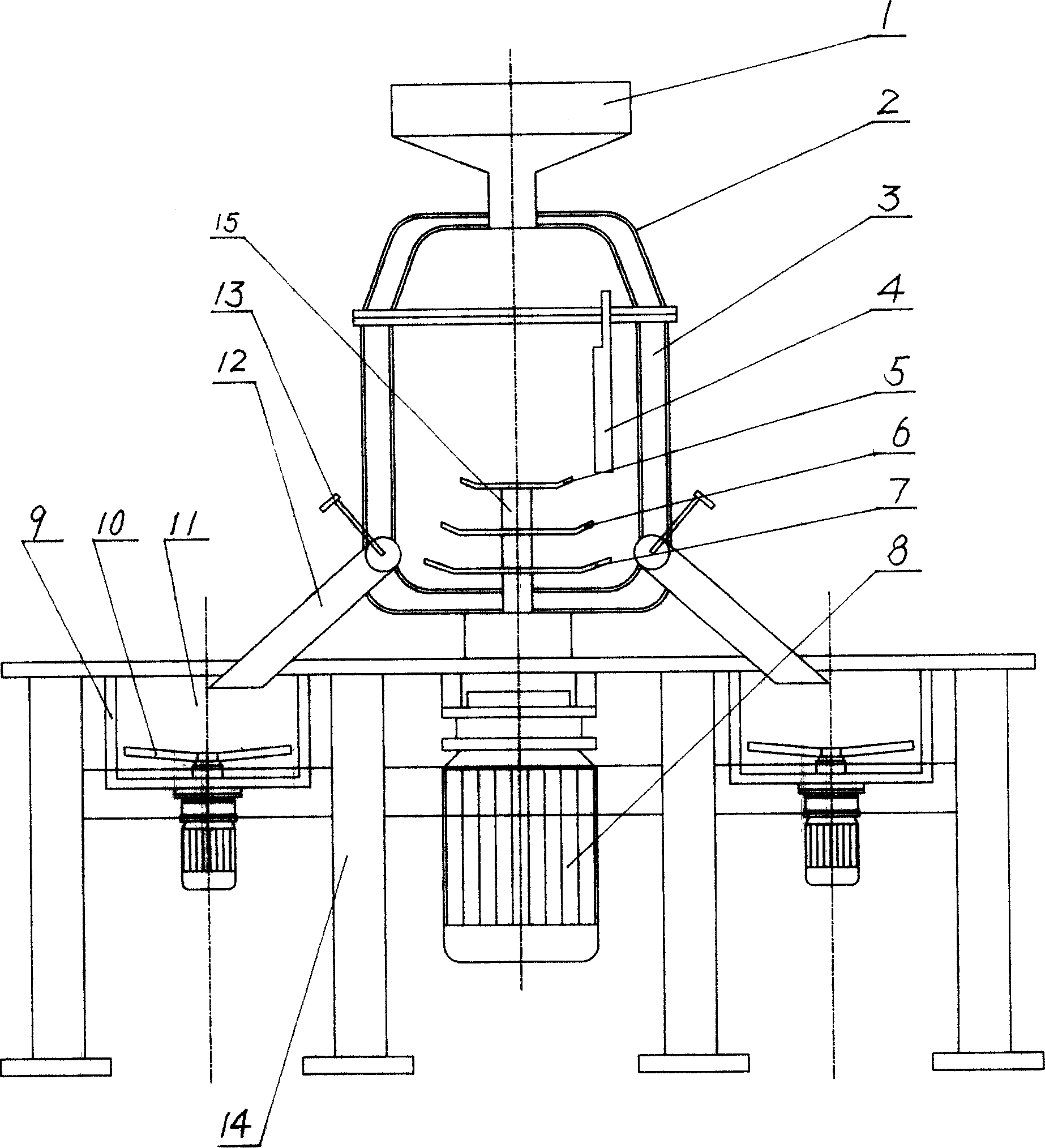

[0008] Referring to the accompanying drawings, the high-speed shear mixing tank 2 is installed above the frame 14, the top of the tank has a receiving hopper 1, and the tank is provided with three layers of mixing knives connected with the transmission shaft, which are respectively ring knives 5, double-wing mixing knives 6, The triangular mixing knife 7, the positions of the mixing knives of each layer are staggered, and the rotation radius is not equal. There is a fixed impact stopper 4 on the side of the mixing knife, and the shell part of the tank has an interlayer 3. The output shaft of the double-stage motor 8 and the transmission shaft 15 directly connected. Two slow cooling tanks 11 are arranged symmetrically under the side of the mixing tank, and are respectively connected by discharge ports 12 with control valves 13. There is a stirring knife 10 in the slow cooling tank, and an interlayer 9 is on the shell.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com