Compact non-PVC film full automatic bag making, filling and sealing machine

A fully automatic and compact technology, applied in the direction of engine components, container manufacturing machinery, mechanical equipment, etc., can solve the problems of poor reliability and stability, difficult debugging, maintenance, poor operation coordination, etc., to achieve reliable performance, improved The effect of stable and reliable operation and simplified equipment operation control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described below in conjunction with the accompanying drawings of the embodiments.

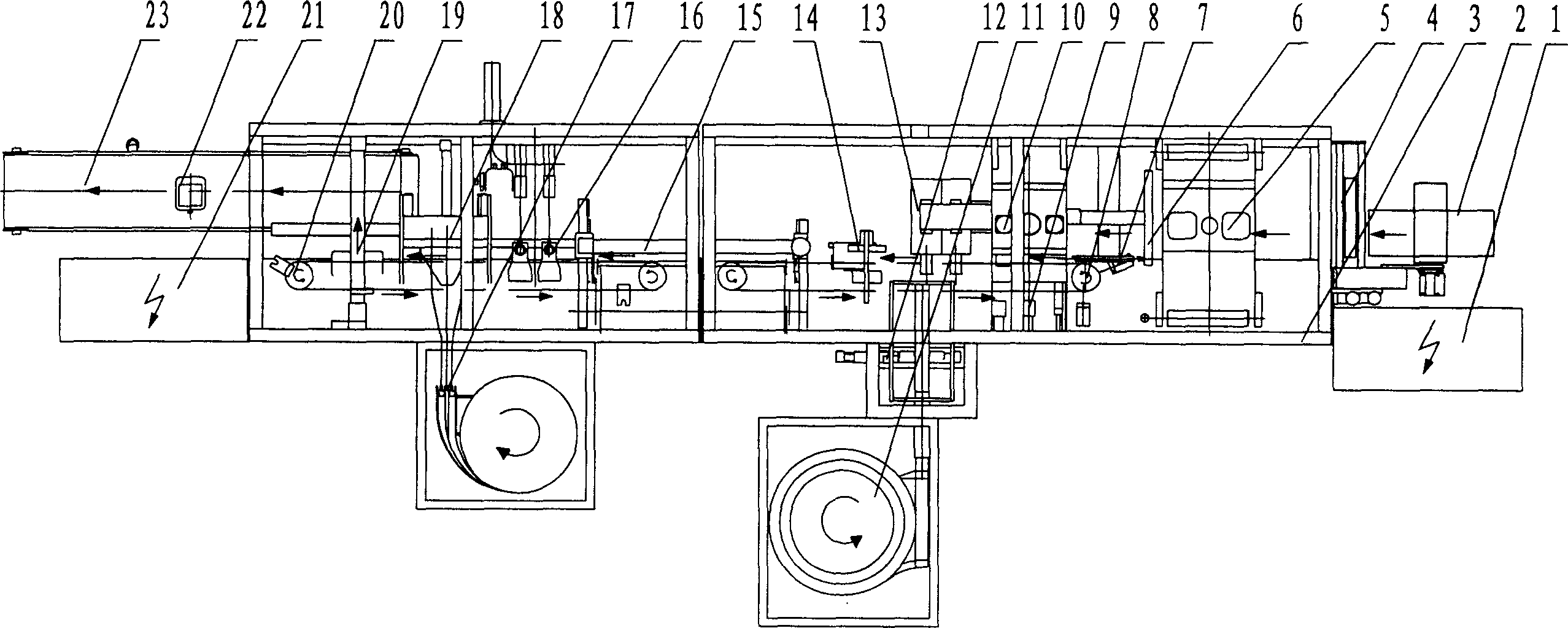

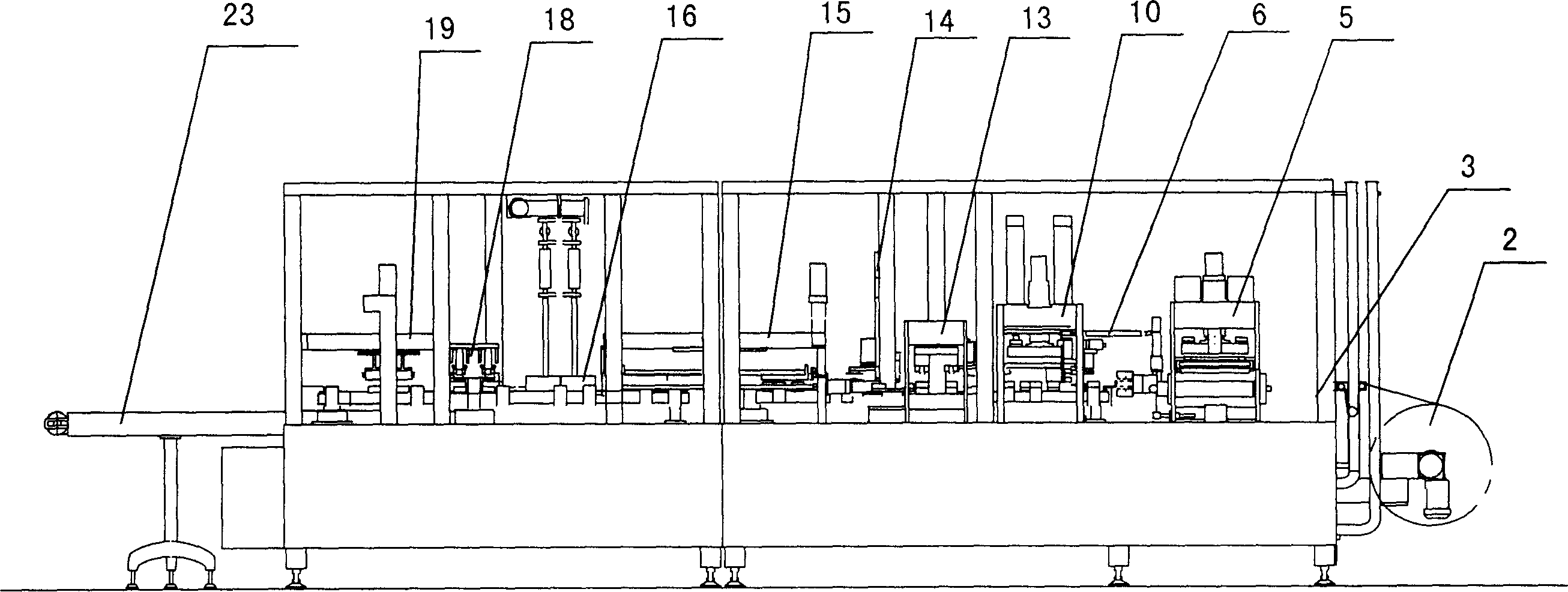

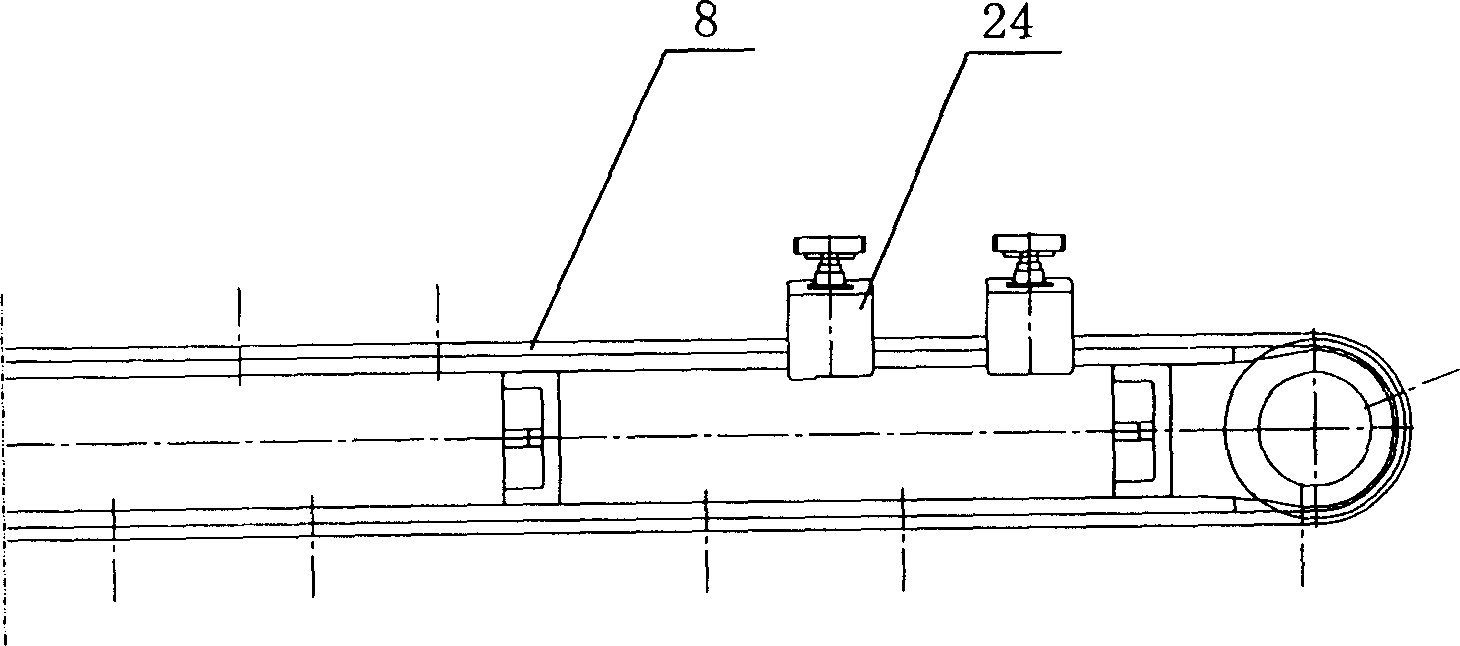

[0069] Such as figure 1 , 2 As shown in Figure 3, the compact non-PVC film full-automatic bag making and filling machine according to the present invention has an overall frame consisting of a mounting frame body 3, a bag making power distribution cabinet 1, a bag making ring conveyor belt 8, and a filling ring Conveying synchronous belt 20 and power distribution cabinet 1, 21; bag making mechanism includes film feeding mechanism 4, printing mechanism 5, film pulling mechanism 6, film welding mechanism 10, primary preheating mechanism 9, secondary preheating mechanism 7, interface Spiral finishing mechanism 11, interface supply mechanism 12, interface welding mechanism 13, waste edge removal mechanism 14; filling mechanism includes filling mechanism 16, sealing cover screw finishing mechanism 17, sealing welding mechanism 18, bag body output mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com