Method for analyzing flexible line components

A flexible wire and component analysis technology, applied in the field of material science, can solve problems such as no analysis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] Embodiment 1 takes the first material as the component analysis object

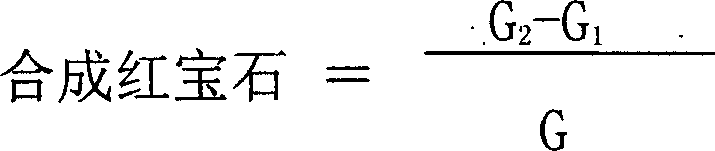

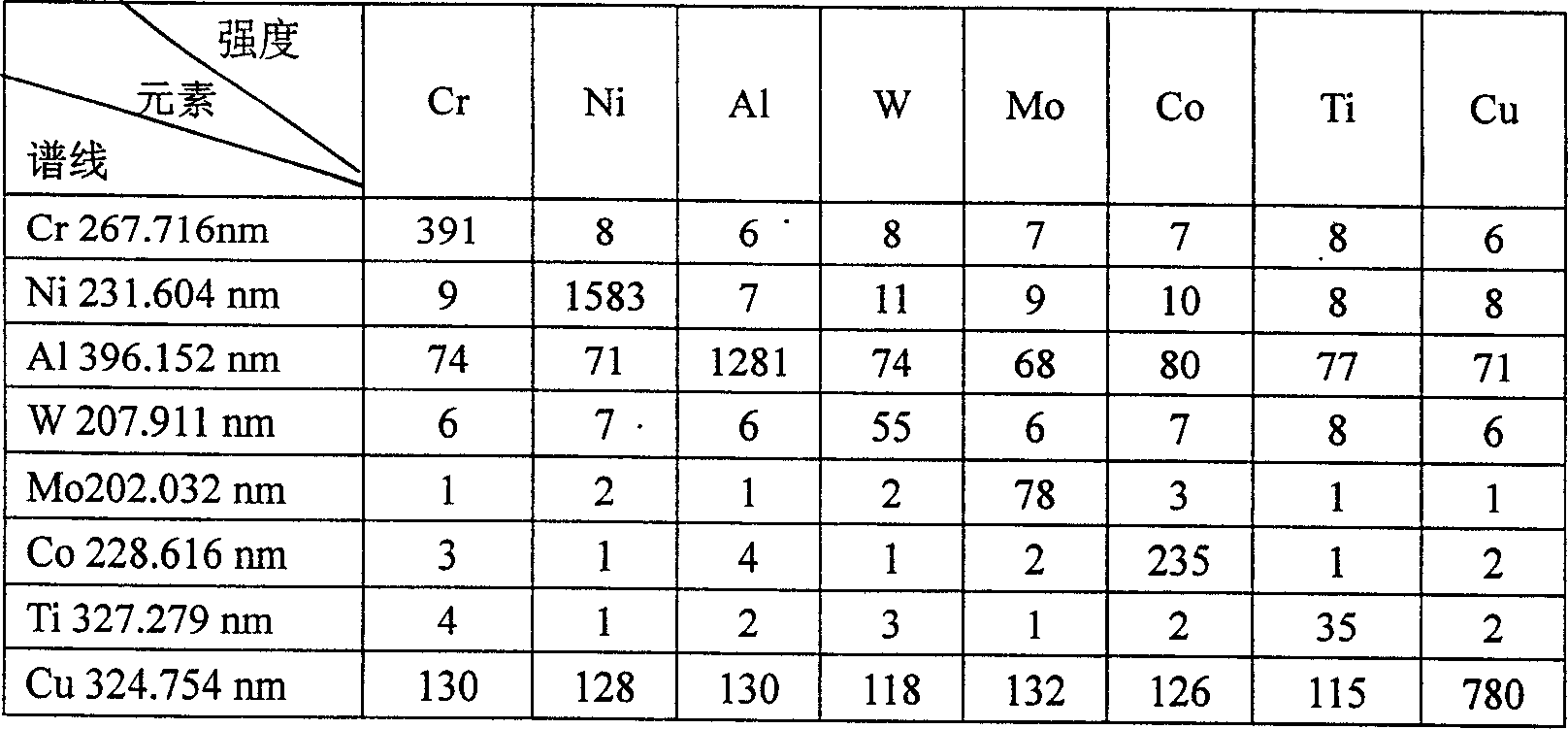

[0090] The first material composition: a certain amount of organic forming agent (the mass percentage range of the organic forming agent in the total mass of the alloy wire material is 7-15%, and the preferred range is 8-12%) and Ni, Al, Cr, W, synthetic ruby, Mo, Ti, Co, Cu; Among them, the relative mass content of other components except organic forming agents is: Ni: 27~33; Al: 8.0~13.0; Cr≤1.5; W≤ 1.5; synthetic ruby: 39.0-44.0; the contents of Mo, Ti, Co, and Cu are measured;

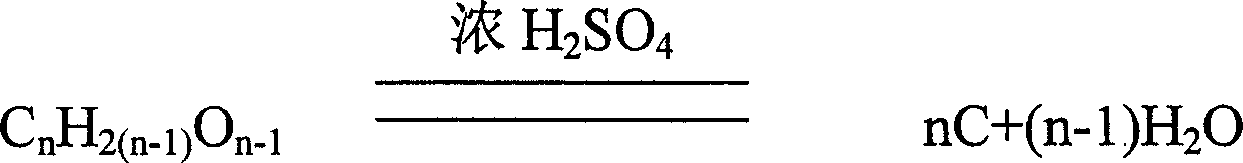

[0091] Preparation of the test solution: Accurately weigh 0.1000g of the sample into a 200ml polytetrafluoroethylene beaker, add about 10ml of concentrated sulfuric acid and heat it on an electric furnace at low temperature until the sample is carbonized and decomposed, then remove and cool. Thereafter, according to the ratio of aqua regia: concentrated hydrochloric acid: concentrated nitric acid = (1 ~ 5): 1; (prefera...

Embodiment 2

[0103] Embodiment 2 takes the second material as the component analysis object

[0104] The second material: a certain amount of organic forming agent (the mass percentage range of the organic forming agent in the total mass of the alloy wire material is 7-15%, and the preferred range is 8-12%) and Ni, Al, Composed of Cr, W, Mo, Ti, Co, Cu, among them, the relative mass content of other components except the organic forming agent is: Ni: 52~57; Al: 15.0~18.0; W≤2.0; where Cr, Mo , Ti, Co, Cu content is measured;

[0105] Preparation of the test solution: Accurately weigh 0.1000g of the sample into a 200ml polytetrafluoroethylene beaker, add about 10ml of concentrated sulfuric acid and heat it on an electric furnace at low temperature until the sample is carbonized and decomposed, then remove and cool. Thereafter, according to the ratio of aqua regia: concentrated hydrochloric acid: concentrated nitric acid = (1 ~ 5): 1; (preferably concentrated hydrochloric acid: concentrated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com