Cell culture system

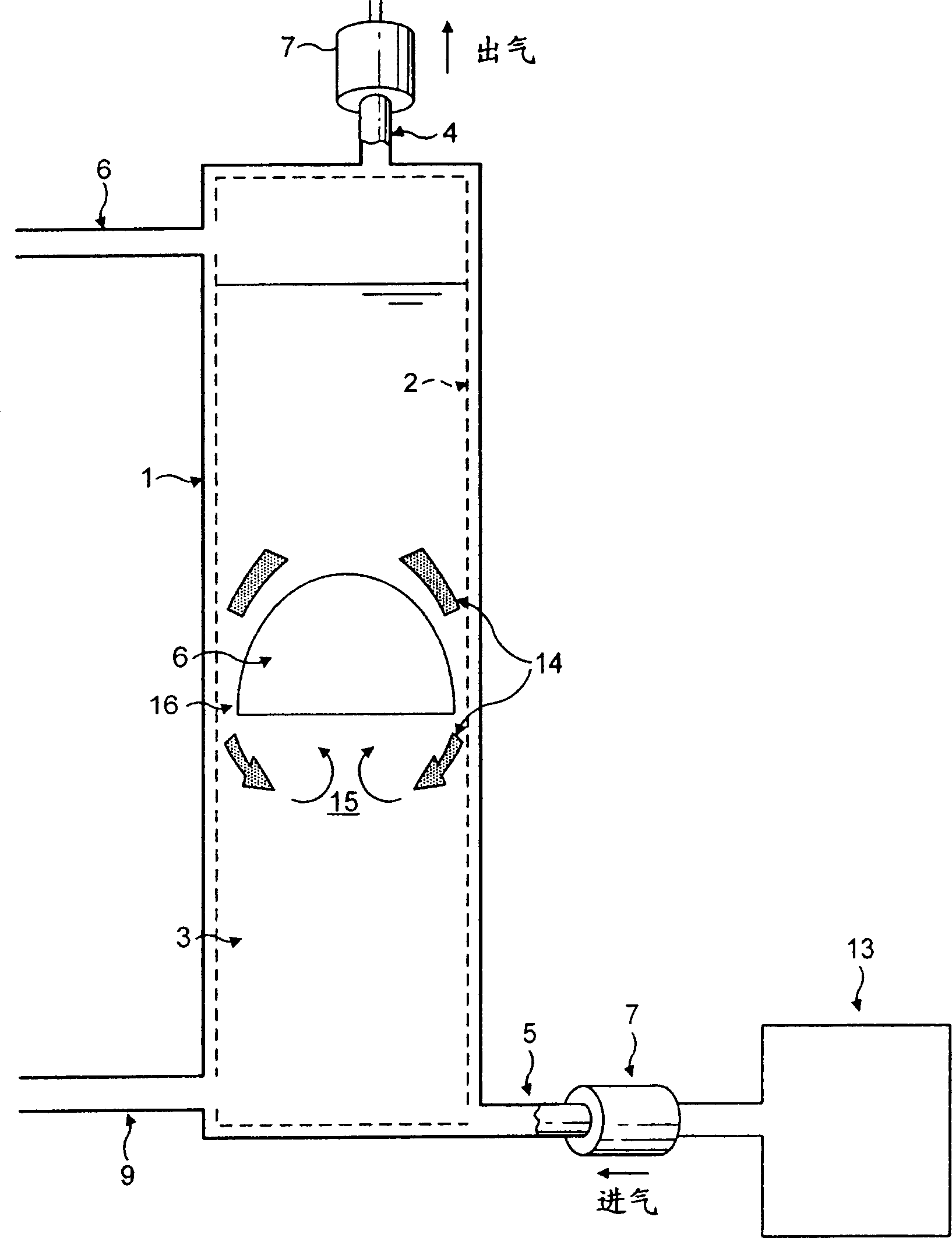

一种细胞、活细胞的技术,应用在植物细胞领域,能够解决复杂、支持设施昂贵、发酵装置高资本成本、折旧利息和资本消耗等问题,达到设计简单、降低维持成本、降低资本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

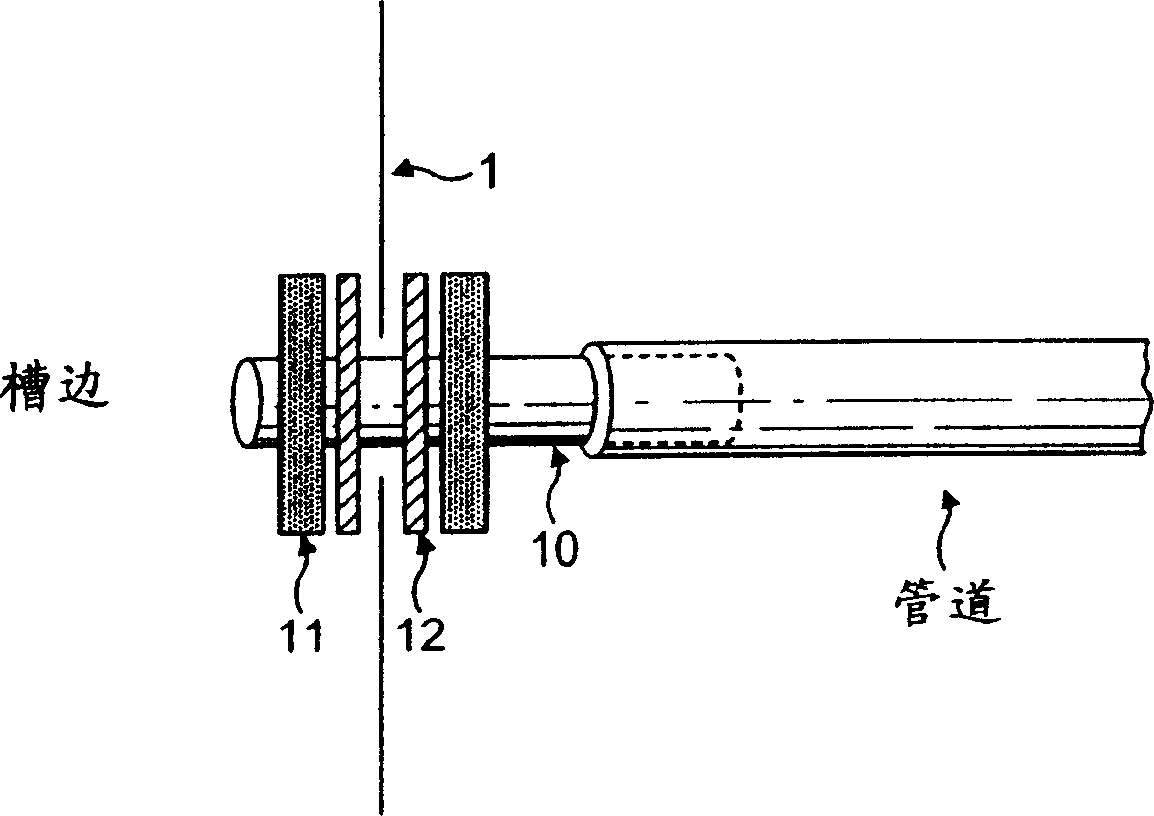

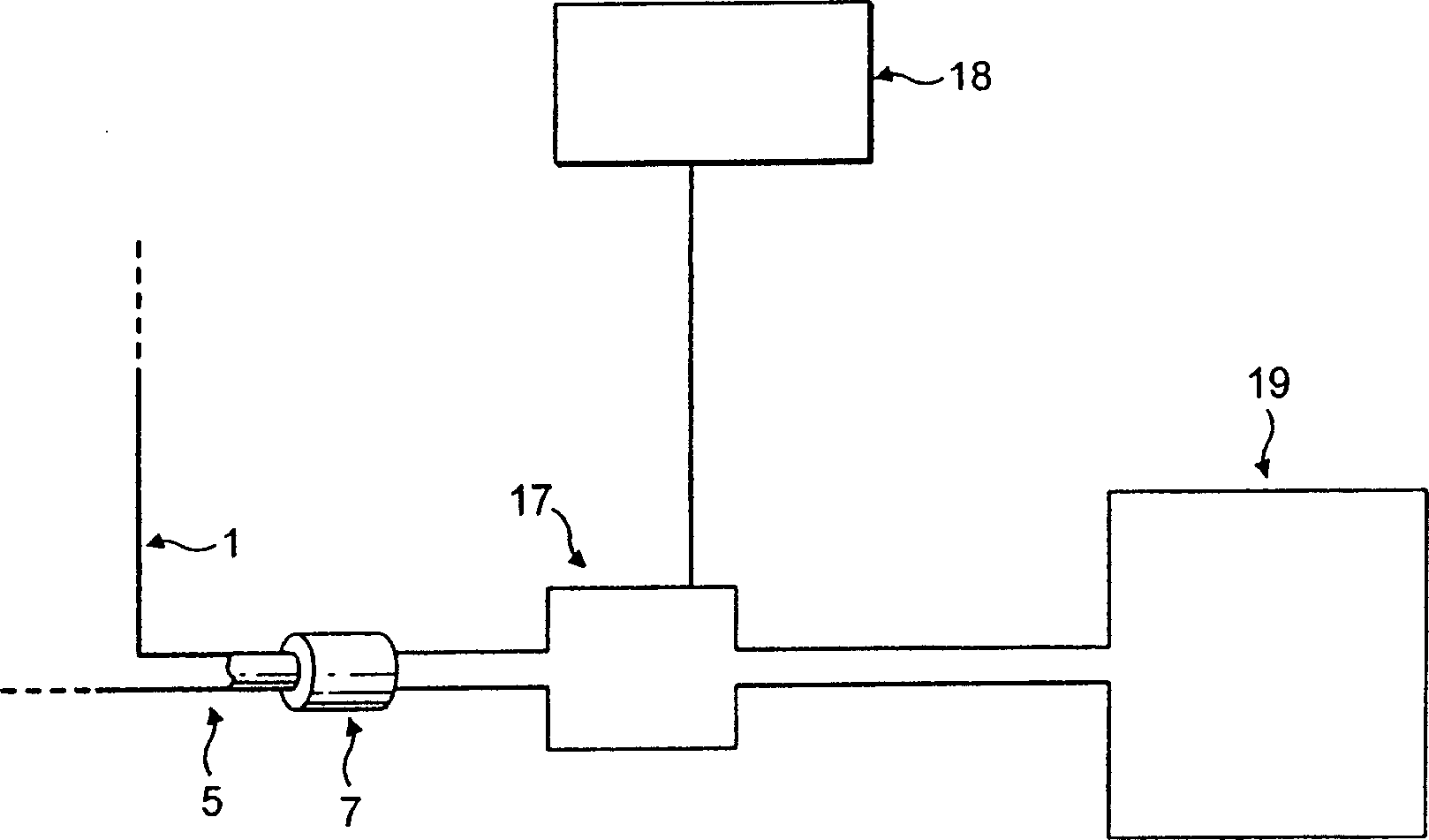

Method used

Image

Examples

Embodiment

[0047] The following examples serve to illustrate some of the products within the scope of the invention and methods of making said products. This example is not to be considered as limiting the invention in any way. Variations and modifications can be made to the invention. That is, the skilled artisan will recognize many variations in this example to cover a wide range of formulations, ingredients, processes and mixtures to rationally adjust naturally occurring levels of the compounds of the invention for a variety of applications.

[0048] EXAMPLE: COMPARATIVE GROWTH USING SOYBEAN CELL CULTURE

[0049] The ability of the present invention to grow soybean cells was demonstrated using batch culture. Even at larger scales, this is comparable to or better than Erlenmeyer flask or stirred tank bioreactors.

[0050] Tissue culture strains of Glycine max (L.) Merr. were originally derived from different species cultured with Gamborg et al's medium (1968) supplemented with 20 g....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com