Cooling system and method for expelling heat from a heat source located in the interior of an aircraft

A cooling system and heat source technology, which is applied in aircraft galleys, aircraft parts, indirect heat exchangers, etc., can solve the problems of large weight, parasitic heat loss, and high maintenance cost of cooling systems, and achieve the effect of low weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

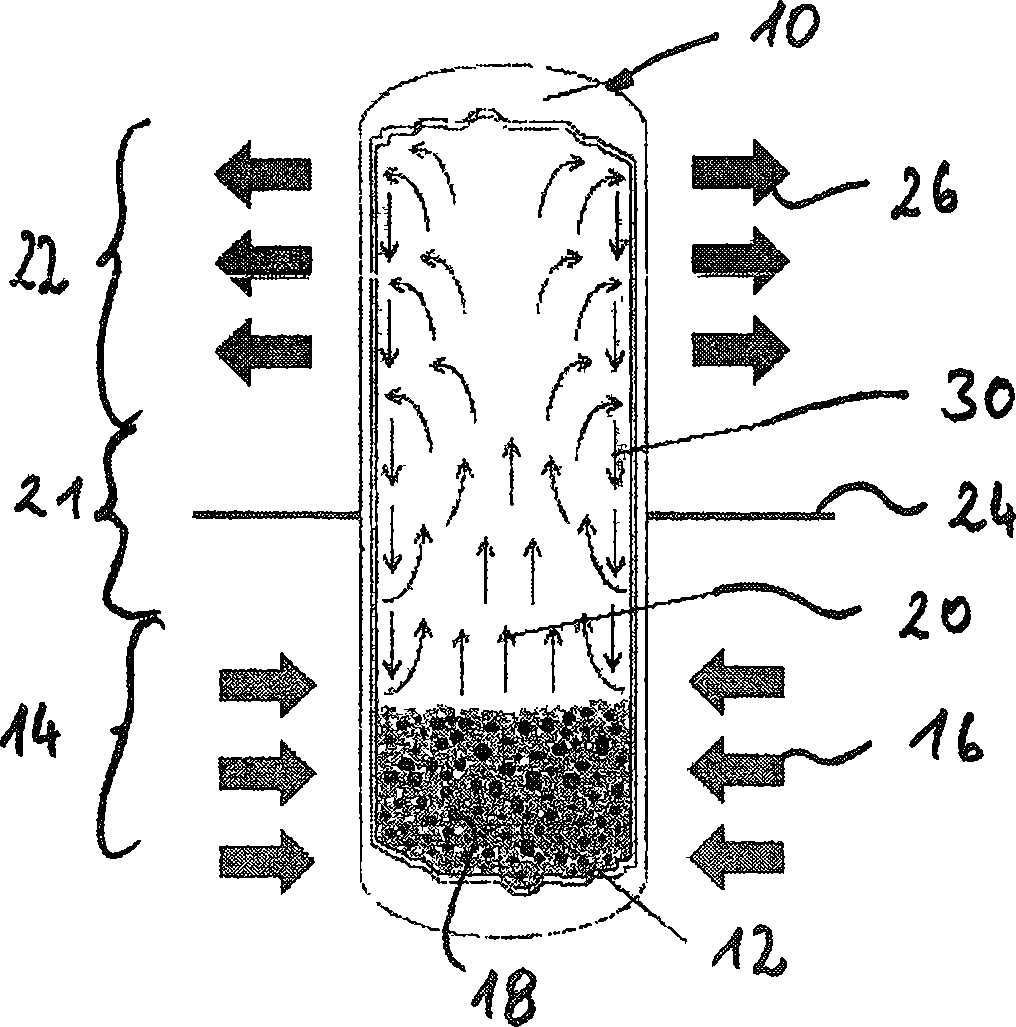

[0032] exist figure 1 A container in the form of a piping system for use with the cooling system according to the invention is shown in FIG. 1 , partly broken away and generally indicated by 10 . The container consists of a round cylindrical tube closed on all sides. In the lower part of the container, the heat transfer medium 12 is shown in liquid state.

[0033] The lower part 14 of the container 10 , which is referred to below as the heat input 14 , is in thermal contact with a heat source, whereby—as indicated by arrow 16 —heat from the heat source enters the heat input 14 of the container 10 . The heat shown by arrow 16 causes the heat transfer medium 12 to boil, as shown by bubbles 18 in the heat transfer medium 12, which eventually evaporates, as shown in figure 1 Indicated by the vertical upward pointing arrow 20.

[0034] Heat transfer medium vapor rises to the top of vessel 10 via transfer 21 and passes from heat sink 14 to heat output 22 whereby it passes through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com