Lamp with double filament

A filament and lamp technology, which is applied to incandescent lamps, fixtures/supports of luminous bodies, electric heating devices, etc., can solve the problems of long and sagging incandescent bodies, and achieve the effect of reducing sagging and simplifying the manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

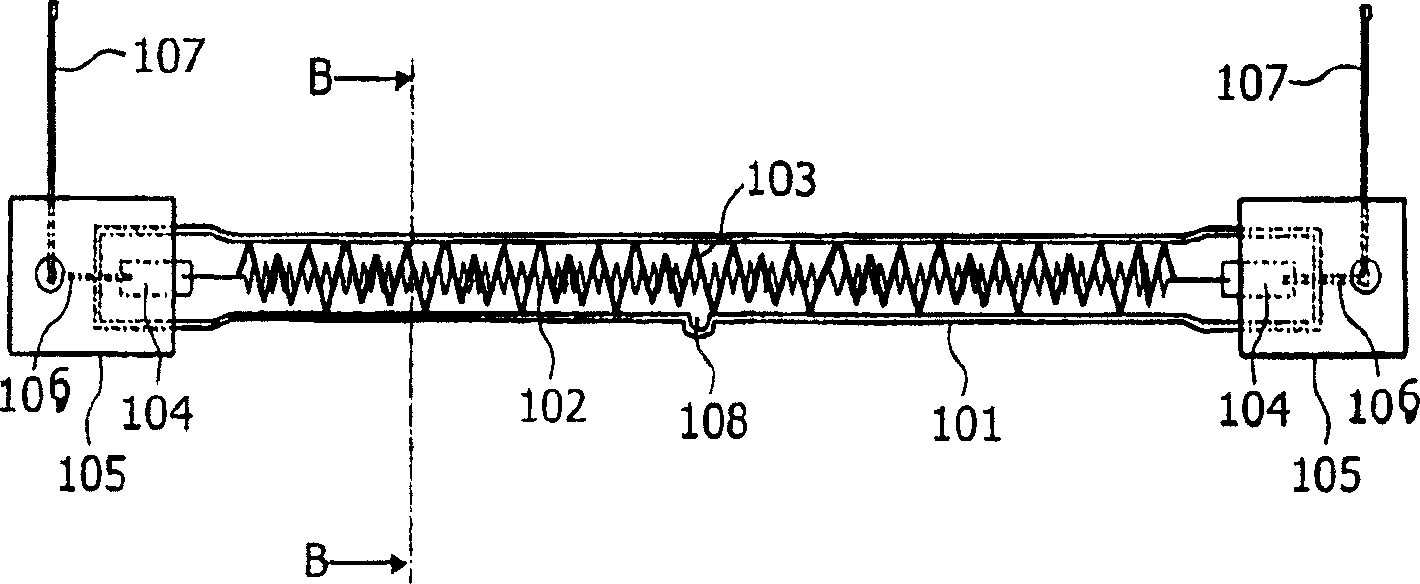

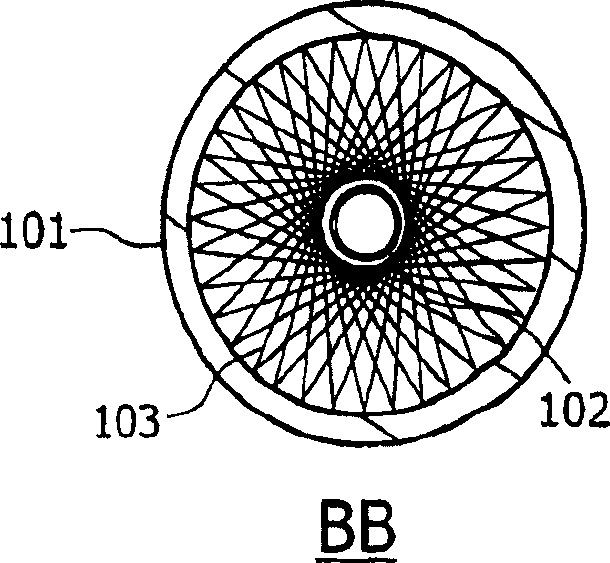

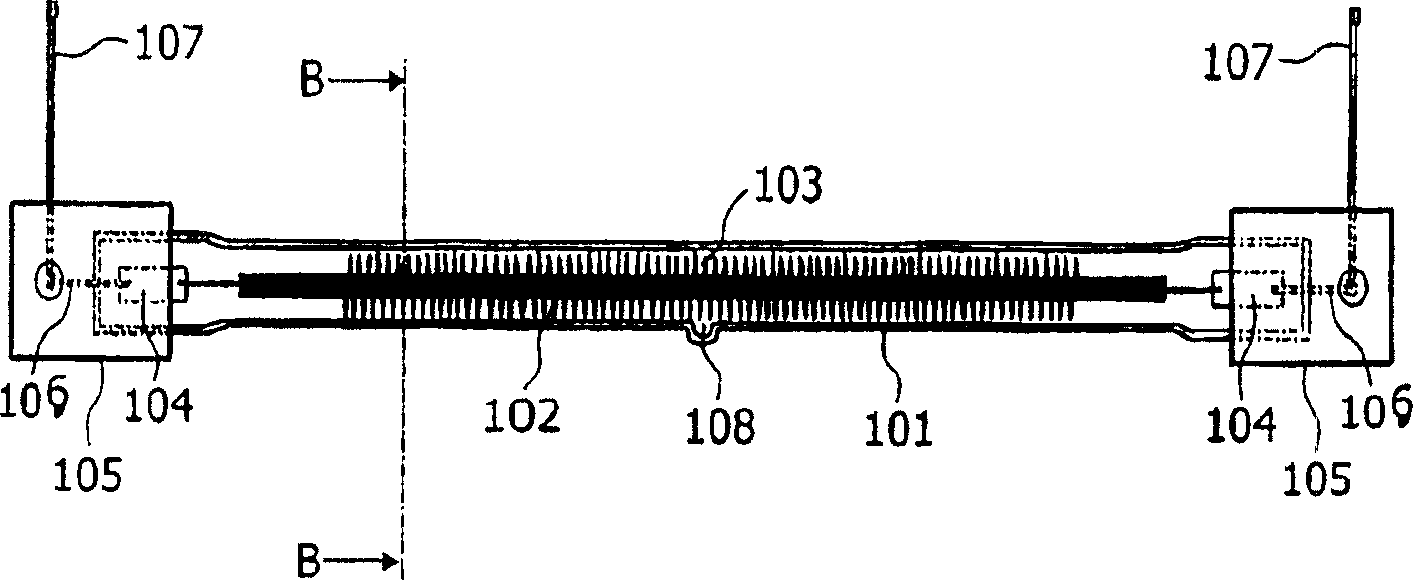

[0015] exist Figure 1a with 1b A lamp according to a first embodiment of the invention is described in . Figure 1b yes Figure 1a An enlarged cross-sectional view of the plane BB of . For ease of description, Figure 1a with 1b The individual dimensions of the parts on the lamp may not correspond. The lamp comprises a lamp tube 101 , an incandescent body 102 , a filament 103 and a power supply conductor 106 . The lamp also comprises a cover 105 , a foil 104 , a current wire 107 and a discharge tube 108 . Although already in Figure 1a A double-ended lamp is shown in , but the invention can also be applied to single-ended lamps.

[0016] The incandescent body 102 is, for example, a tungsten wire having an end connected to a foil 104, for example a molybdenum sheet, to which the end of the incandescent body 102 is welded. The supply conductor 106 is also soldered to the foil 104 . The supply conductor 106 is connected to a current line 107 . This can also be done by sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com