Designing method of claw type rotor

A design method and rotor technology, applied to mechanical equipment, rotary piston pumps, rotary piston machines, etc., can solve problems such as noise and vibration, noise and vibration, and the tip 82, 92 is not smooth and smooth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

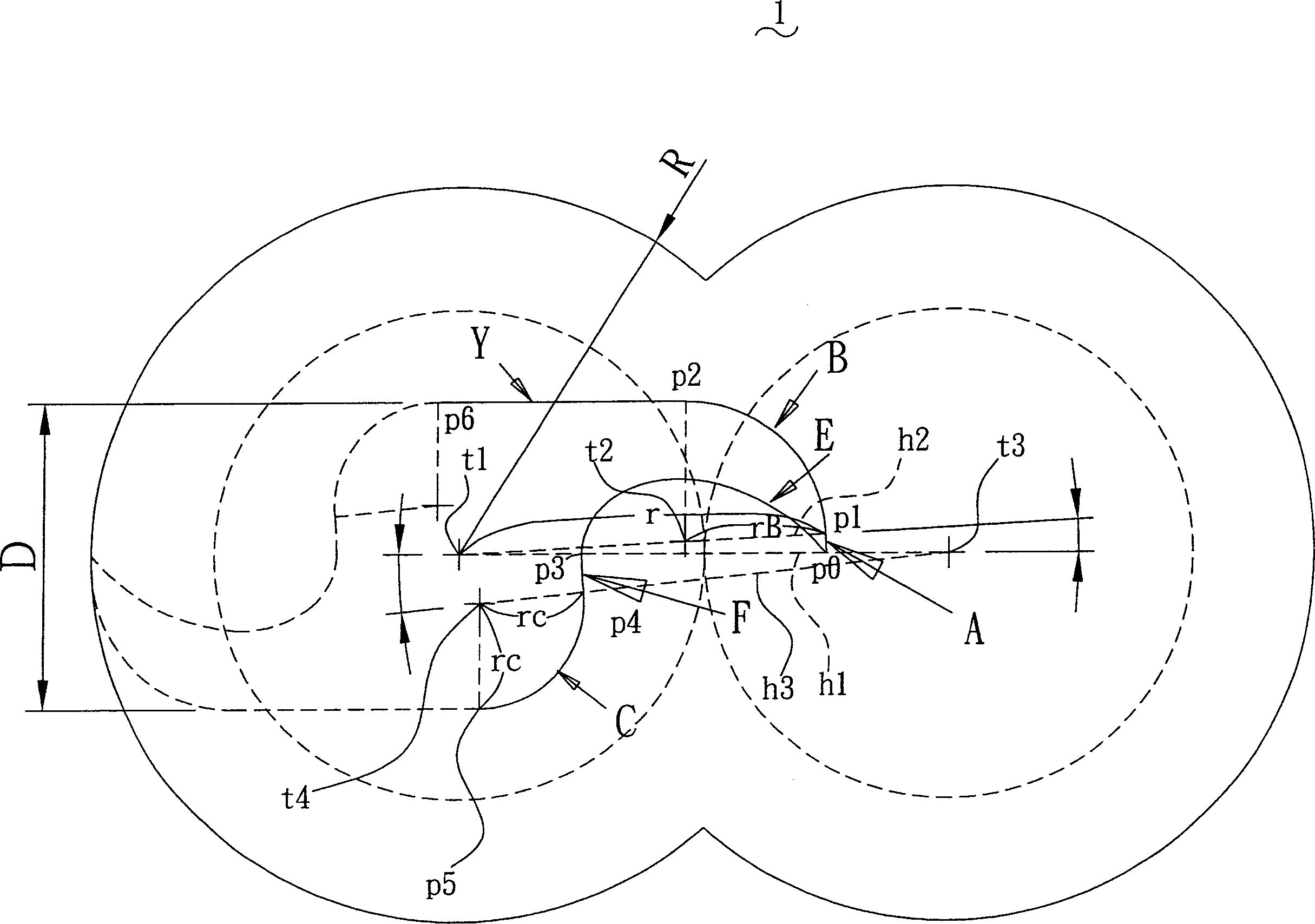

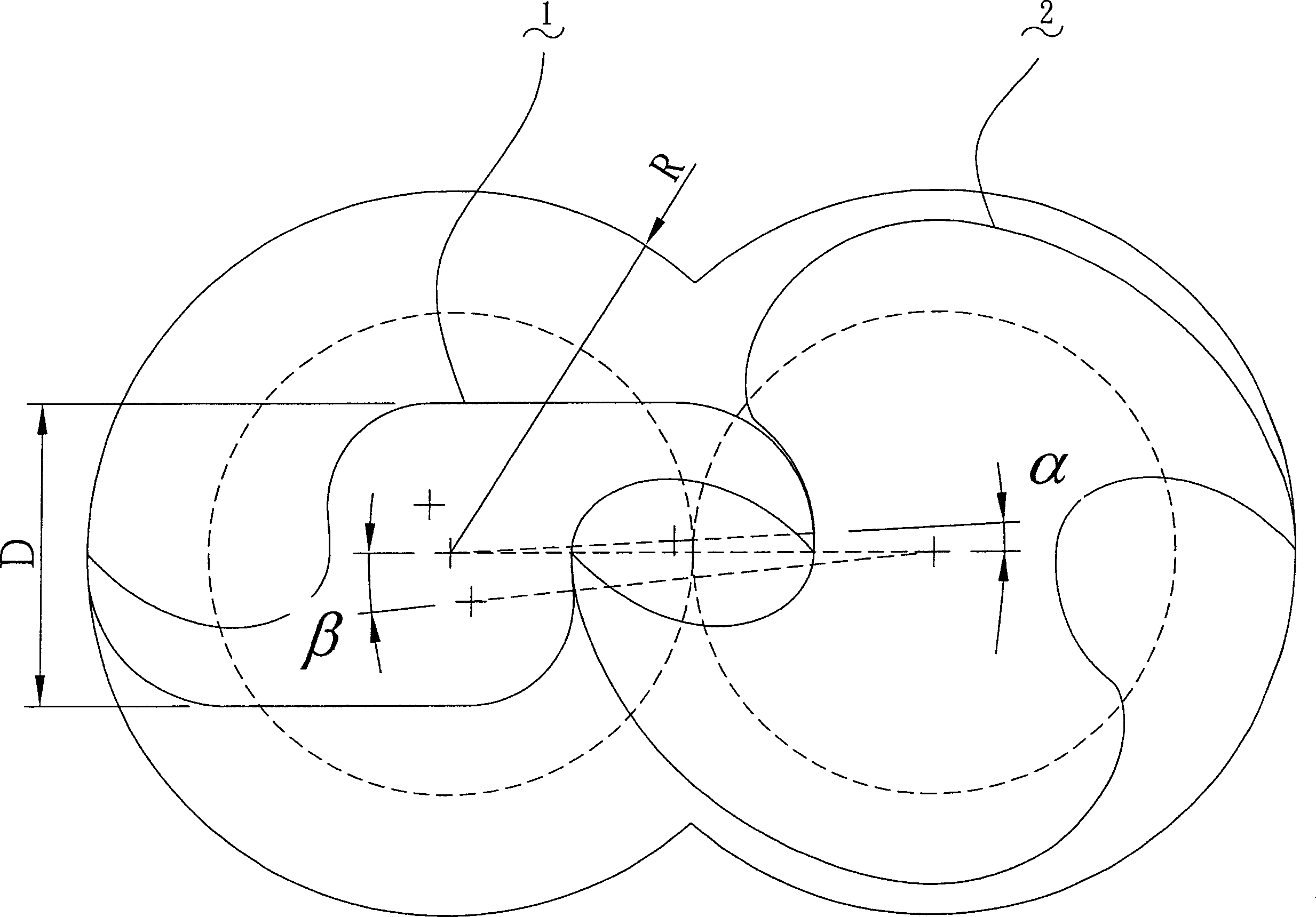

[0031] The claw rotor design method of the present invention is to obtain the shape of the defined rotor 1 first, and then obtain the shape of the conjugated rotor 2 with the conjugate curve, please refer to figure 1 , 2 , obtaining the shape of the defined rotor 1 includes the following steps:

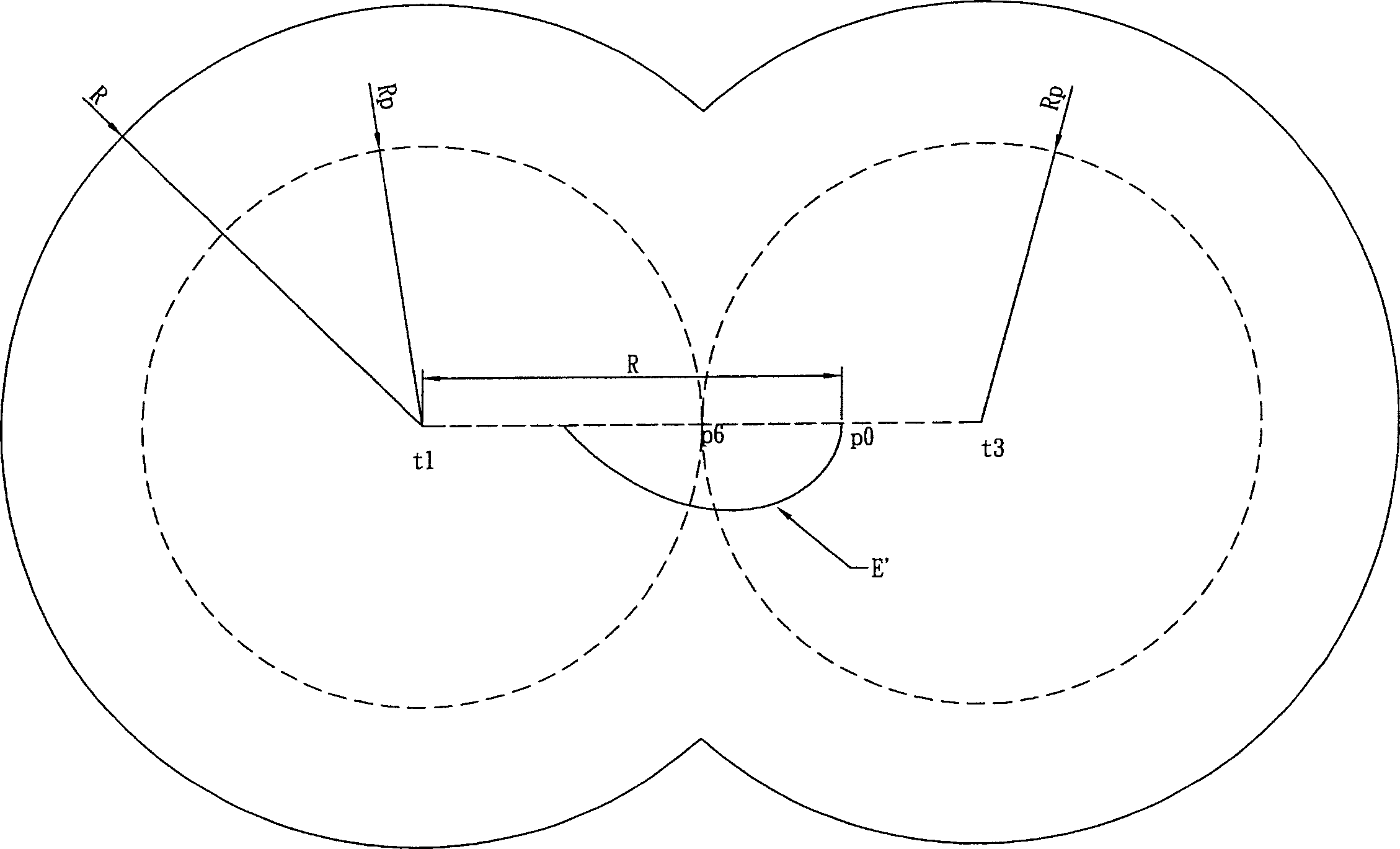

[0032] 1. Define the maximum rotor radius R, define the rotor width D, define the pitch circle radius Rp of the rotor and the conjugate rotor, the centers of the two pitch circles are t1 and t2 respectively, Rp is less than R, and define the maximum rotor radius R and pitch The ratio of the circle radius Rp is R=3Rp / 2.

[0033] 2. Take the center t1 of the pitch circle as the center of the defined rotor, pass through a horizontal line h1, and obtain a point P on the horizontal line h1 0 , this point P 0 The horizontal distance of the circle center t1 is R, from this point P 0 A conjugate curve E' is generated around the center of the pitch circle t1, and the curve E' is relative ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com