Display panel module

A display panel and printed circuit board technology, applied to static indicators, instruments, identification devices, etc., can solve the problems of reducing manufacturing pass rate and increasing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

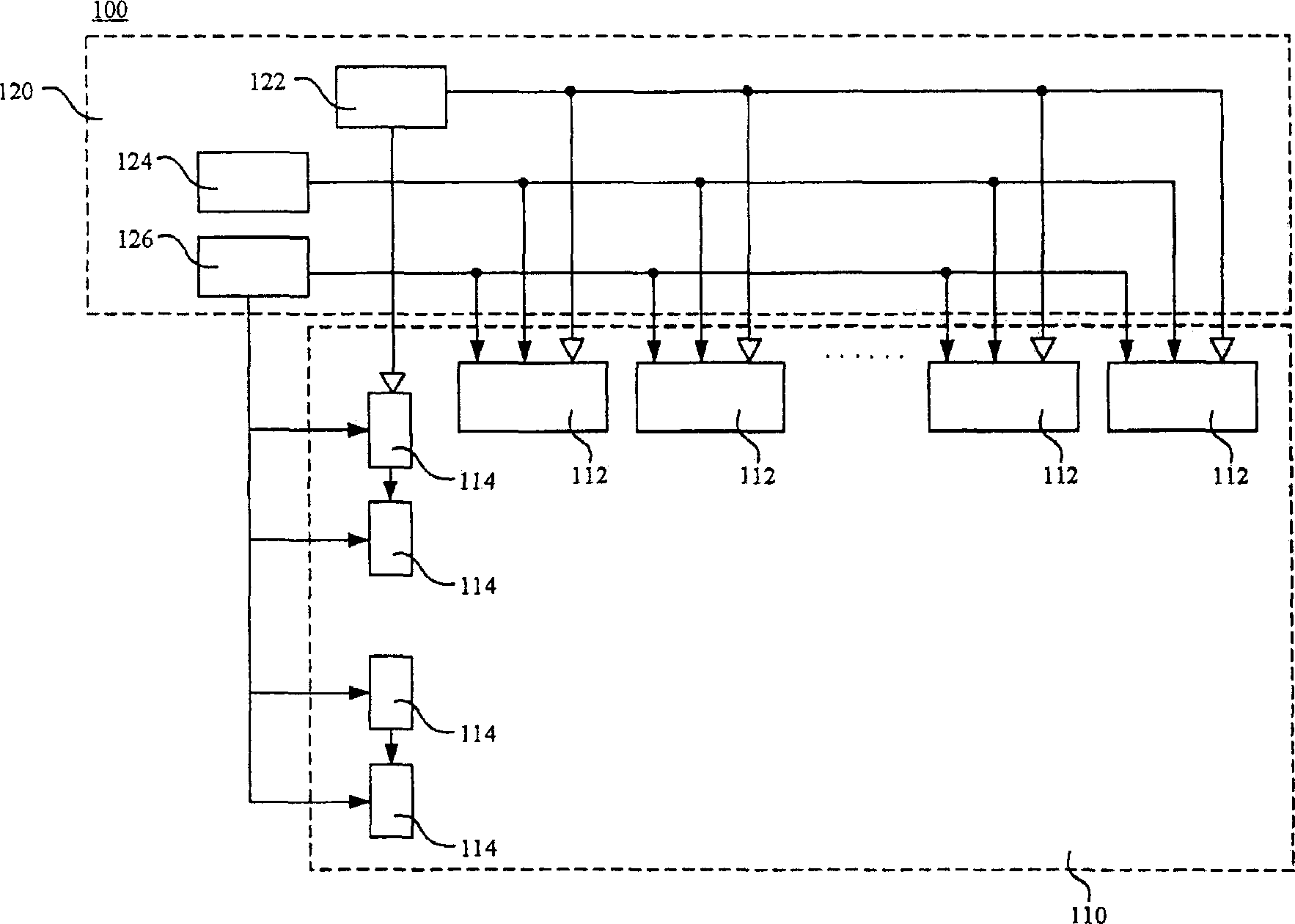

[0040] In the present invention, the data driving chips are arranged on the display panel in series, and at least two flexible printed circuit boards are used to transmit the data signal and the power signal respectively, so that the area of the printed circuit board can be reduced to reduce the production cost. Furthermore, through the configuration of the relative positions between the data-driven chip and the flexible printed circuit board, the internal or external electrical connections between the signal contacts of the data-driven chip, etc., the present invention can further reduce the required flexible printed circuit board. The number of circuit boards is reduced, and the manufacturing yield is improved and the production cost is reduced.

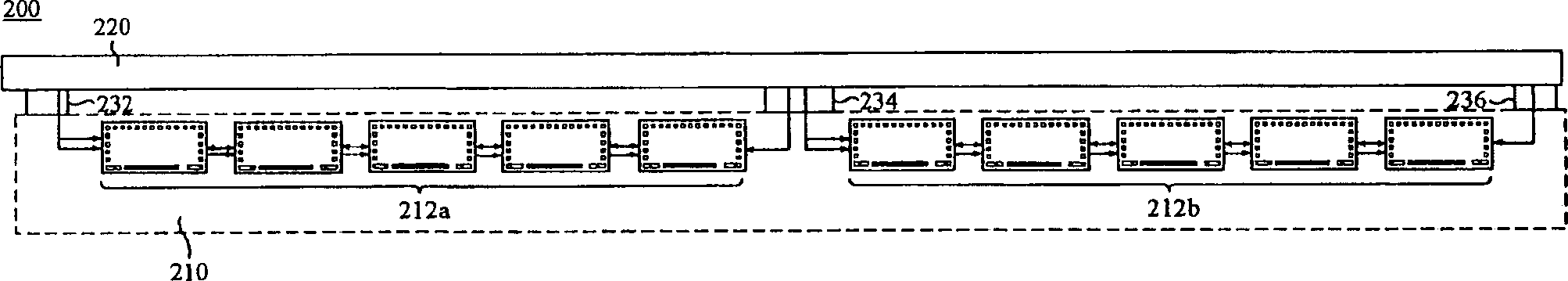

[0041] figure 2 A schematic diagram of a display panel module according to a preferred embodiment of the present invention is shown. The display panel module 200 includes a display panel 210, a printed circuit board 220, a firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com