Hydrogenation method for producing catalytic reforming raw material

A technology for catalytic reforming and raw materials, applied in refining to remove heteroatoms, etc., can solve problems such as high investment and operation costs and complicated processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

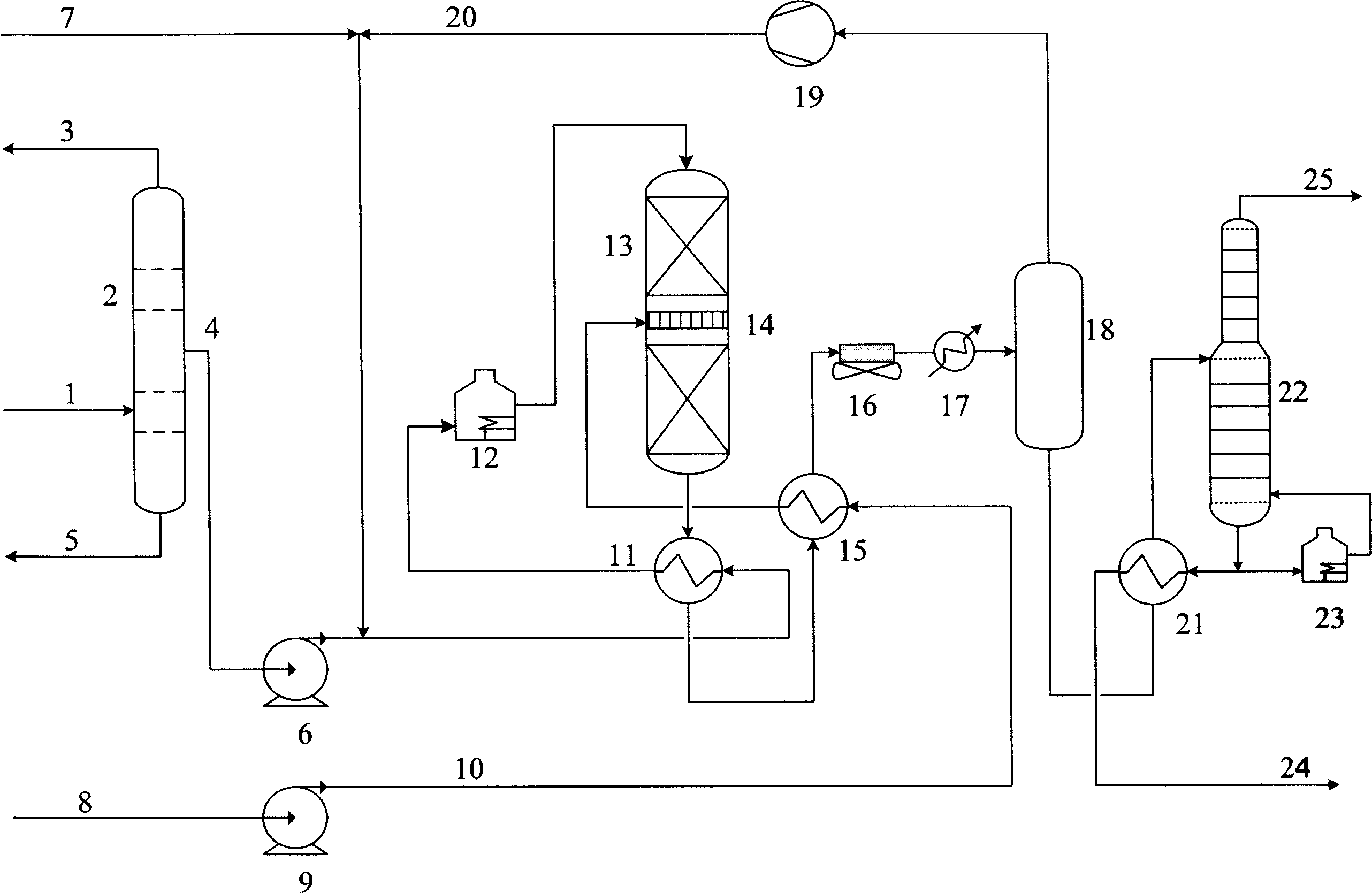

Method used

Image

Examples

Embodiment

[0033] A catalytically cracked gasoline was subjected to fractional distillation, and the mid-weight gasoline fraction (distillation range 79-175°C) was extracted as feedstock A; a straight-run naphtha was used as feedstock B. The properties of the feedstock are shown in Table 1.

[0034] In this embodiment, the reactor is divided into two beds, a quench box and an oil-gas distributor are arranged between the two beds, the first bed and the second bed are filled with the same hydrofinishing catalyst, and the first bed hydrofinishing catalyst The loading volume ratio of the two-bed hydrotreating catalyst and the second-bed hydrotreating catalyst is 55:45, and the total catalyst loading volume of the reactor is 37.1m 3 .

[0035] The raw material oil A and hydrogen enter the first bed of the reactor after being heated to carry out hydrofining reaction. The inlet temperature of the first bed is 250°C, and the outlet temperature of the first bed is 370°C. After the heat exchange,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com