Catalytic cracking conversion method of hydrocarbon raw material and its device

A technology for catalytic cracking and raw materials, which is applied in the field of catalytic cracking and conversion of hydrocarbon raw materials for reducing the olefin content of gasoline, can solve the problems of large temperature difference in the reaction process, poor product selectivity, unfavorable regeneration, etc. ratio, loss reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

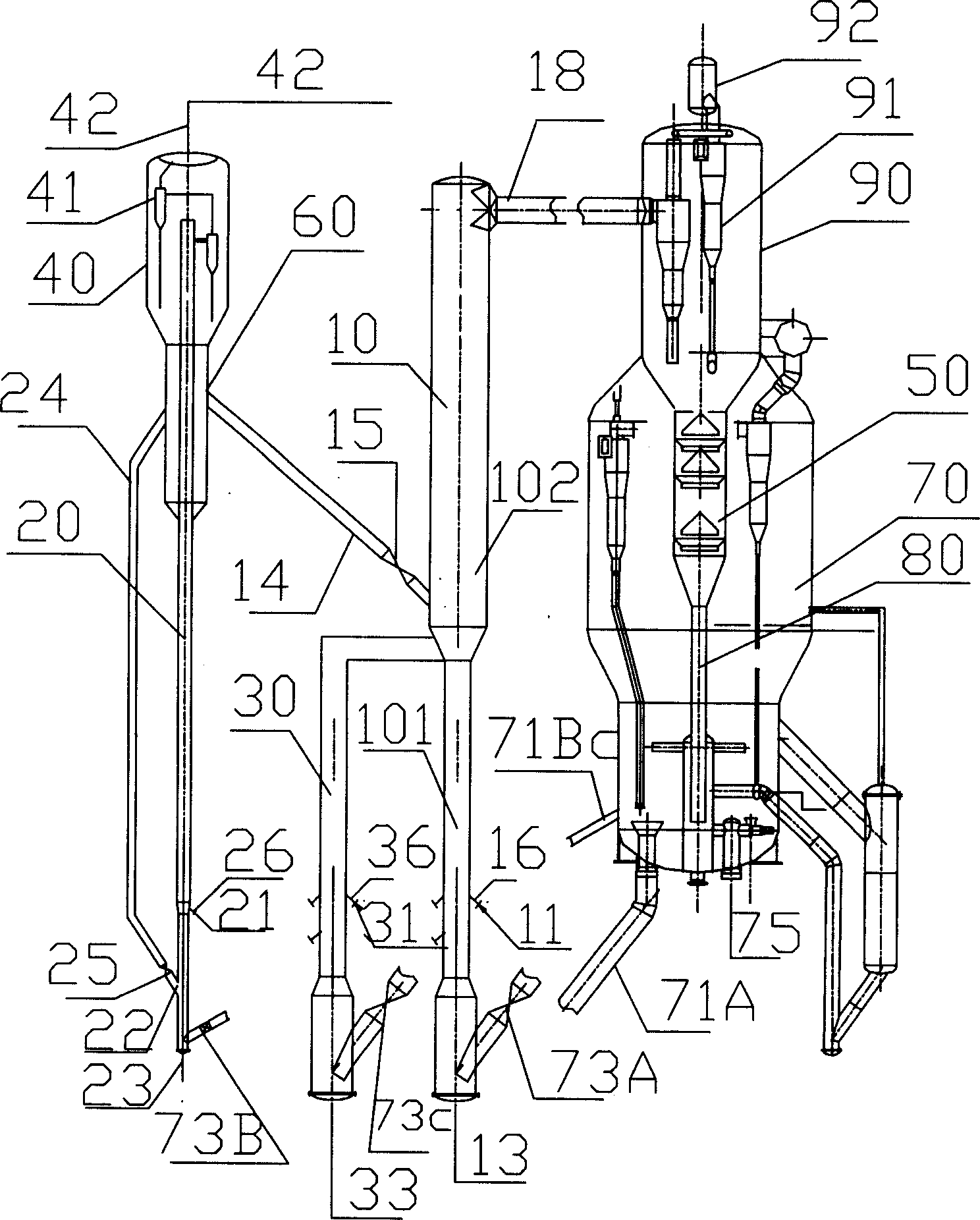

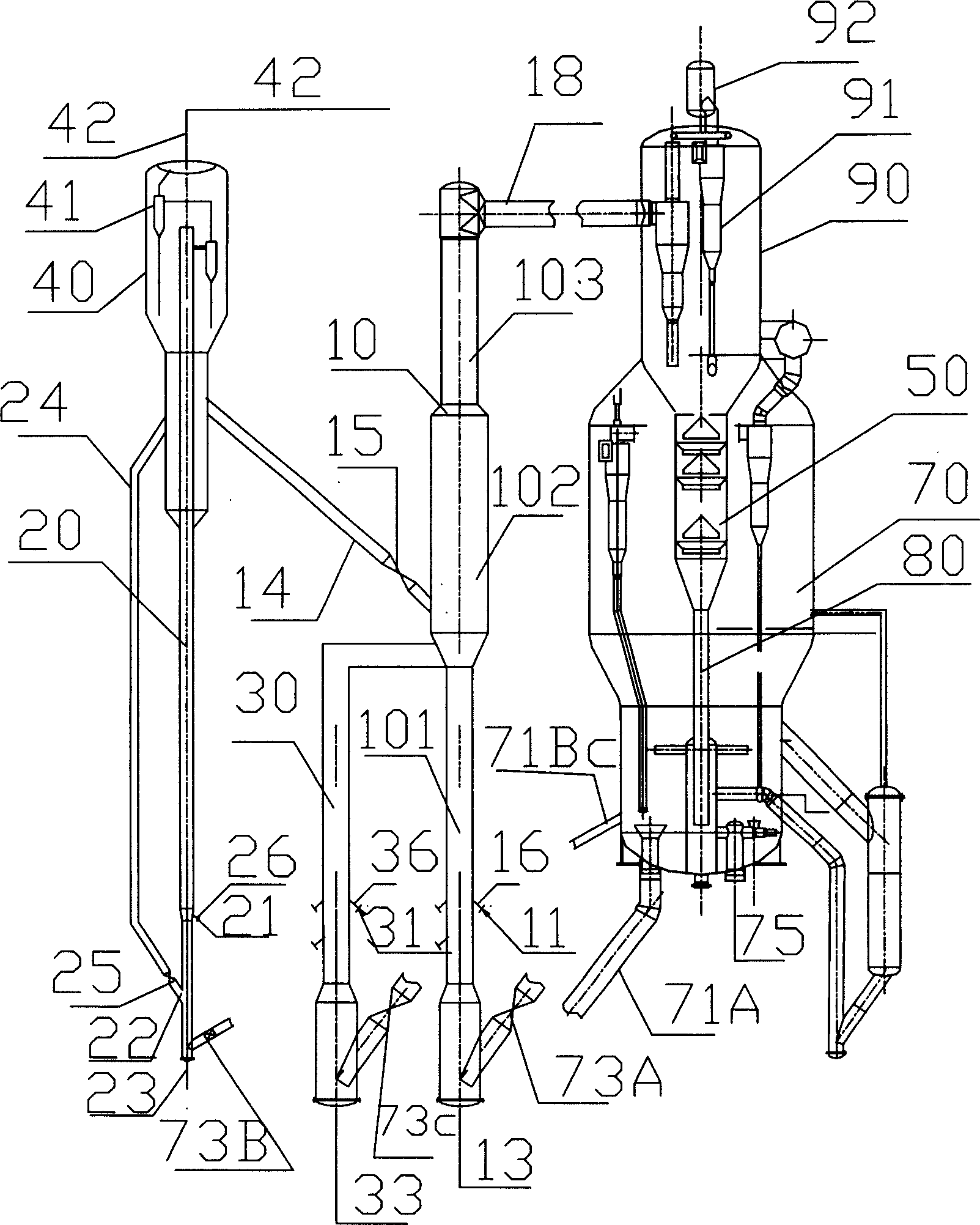

[0027] Embodiment 1, present embodiment adopts device to see figure 1 , beside the heavy oil reactor 10 of the heavy oil reaction-regeneration device, a gasoline reactor 20 sharing the regeneration device is connected in parallel, the outlet of the gasoline reactor 20 is provided with a settler 40, and the gasoline catalyst stripper 60 under the gasoline reaction settler 40 A catalyst delivery pipe 14 is provided between the second reaction zone 102 of the heavy oil reactor 10 . A catalyst return pipe 24 is provided between the gasoline catalyst stripper 60 provided under the gasoline settler 40 and the bottom of the gasoline reactor 20 . The first reaction zone (catalytic cracking reaction zone) of the gasoline reactor 20 and the heavy oil reactor 10 is a conventional riser. 41 is a gas-solid separator.

[0028] The reaction materials are: atmospheric pressure heavy oil, 100t / h heavy oil, gasoline feedstock is heavy oil to react self-produced gasoline; heavy oil is preheate...

Embodiment 2

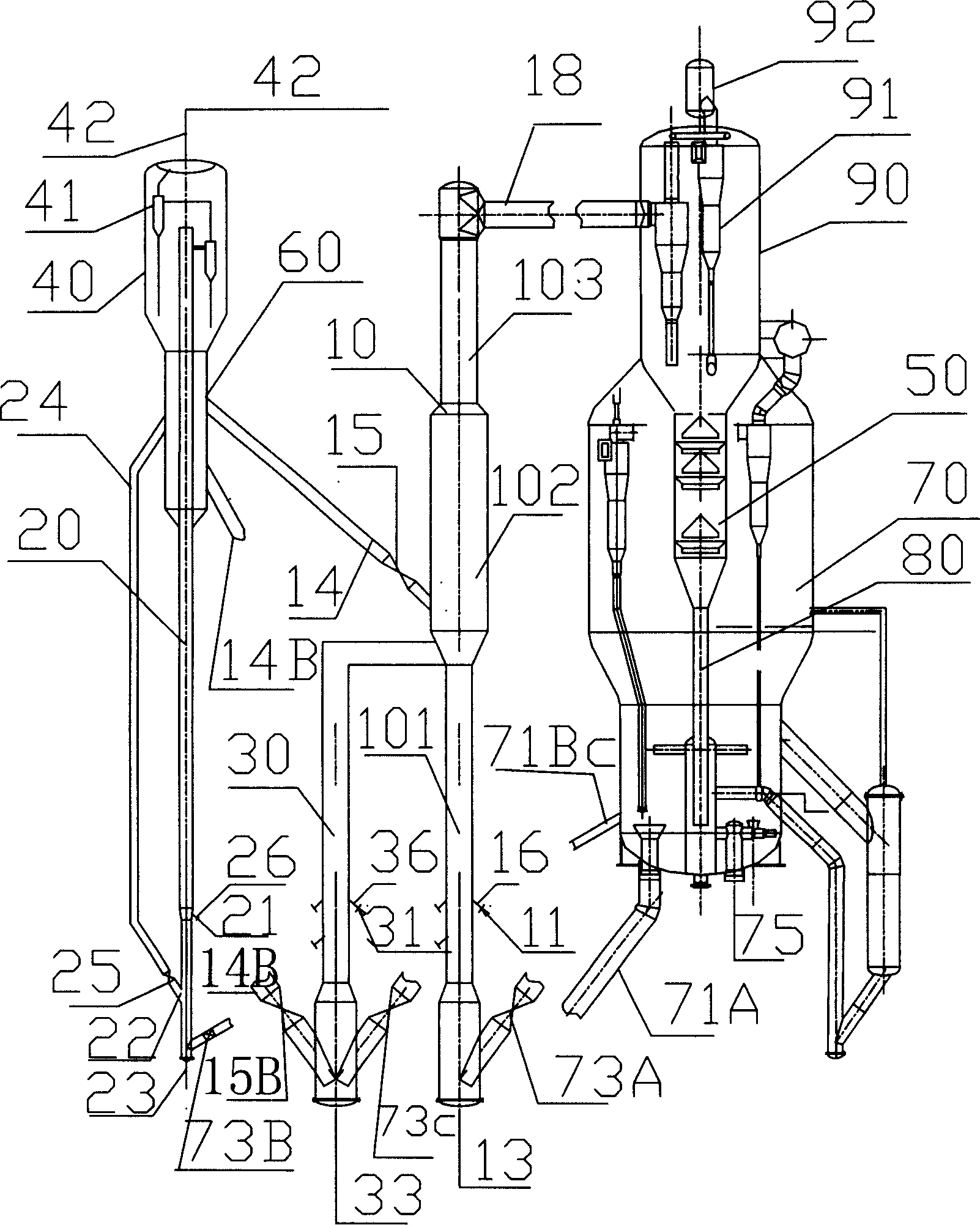

[0031] Embodiment 2, the device structure of this embodiment see image 3 , and the structural difference in Example 1 is that a catalyst relay delivery pipe 14B is provided between the gasoline catalyst stripper 60 and the bottom of the refined oil riser 30, and the second reaction zone 102 for the heavy oil reaction adopts a fluidized bed type.

[0032] The reaction materials are: Daqing atmospheric heavy oil, 100t / h heavy oil, gasoline feed is catalytic gasoline from other devices, 40t / h; heavy oil preheating 220°C, gasoline 40°C; The two channels respectively enter the respective catalytic cracking reaction risers, and the gasoline enters the reactor in two channels; the reaction temperature in the raw oil cracking zone is 510°C, and the reaction time is 1.0s; The reaction temperature is 485°C, the reaction time is 4s; the gasoline reaction temperature is 400°C, the reaction time is 4s; the catalyst mixing temperature is 620°C before the reaction in the oil refinery riser,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com