Cotton-network guide device of combing machine

A guide device and combing machine technology, applied in the direction of combing machine, textile and papermaking, fiber processing, etc., can solve the problems of entanglement and adsorption of the output cotton web, affecting the quality of the output cotton web, downtime and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

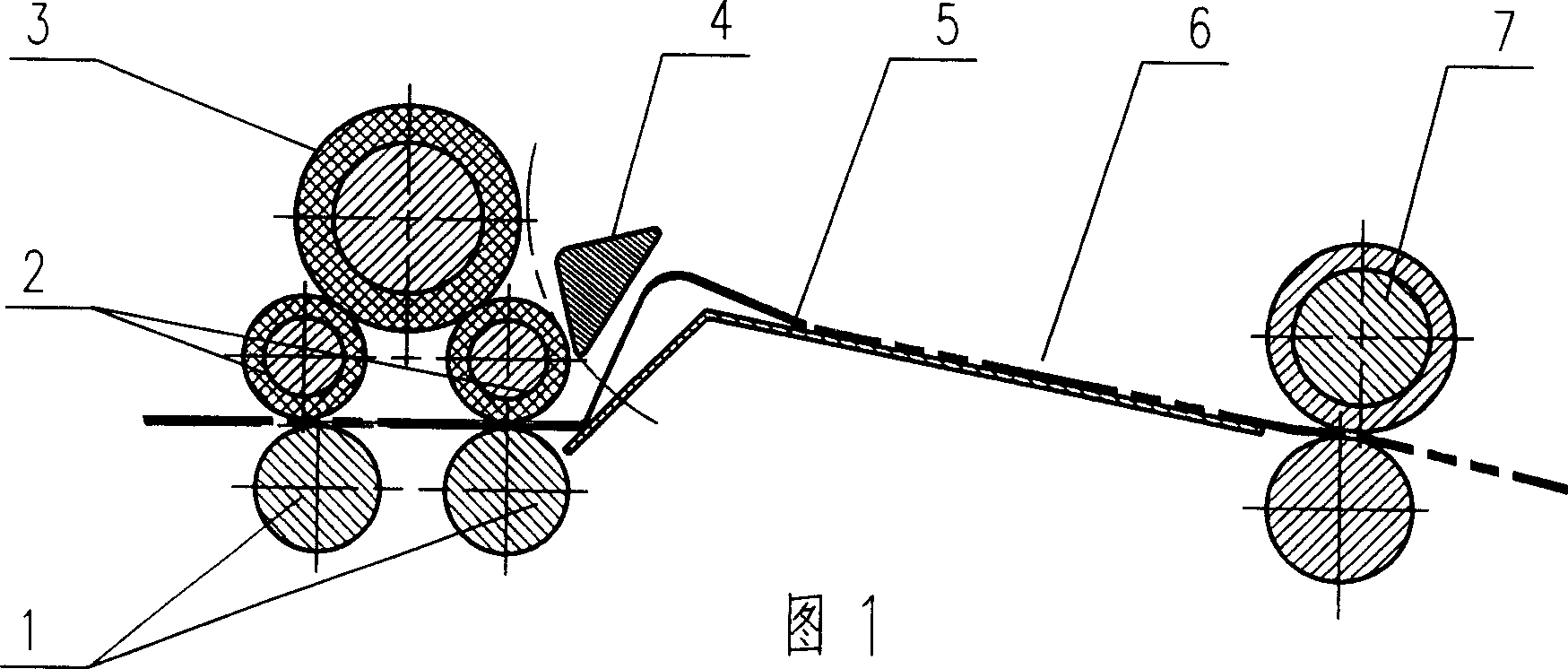

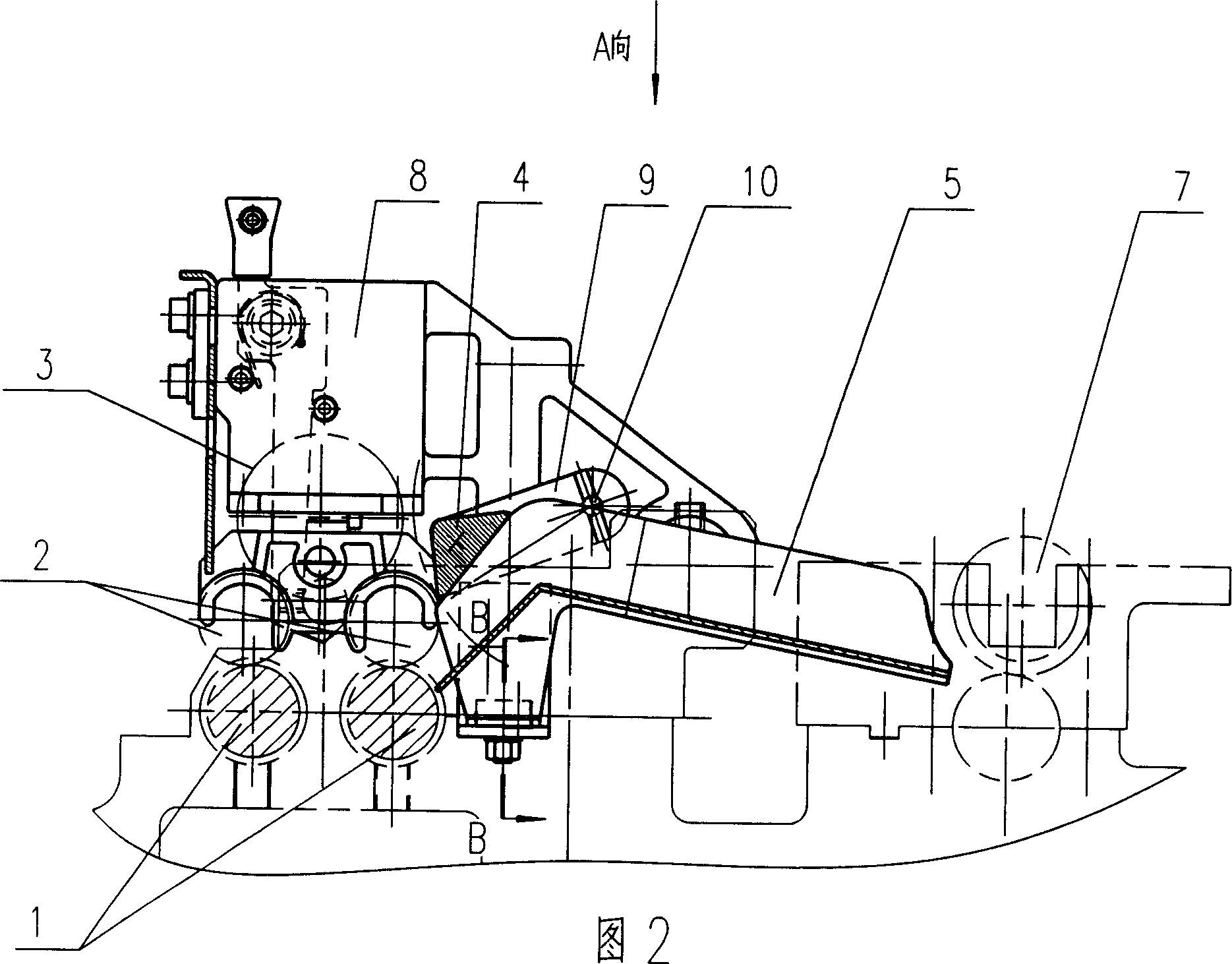

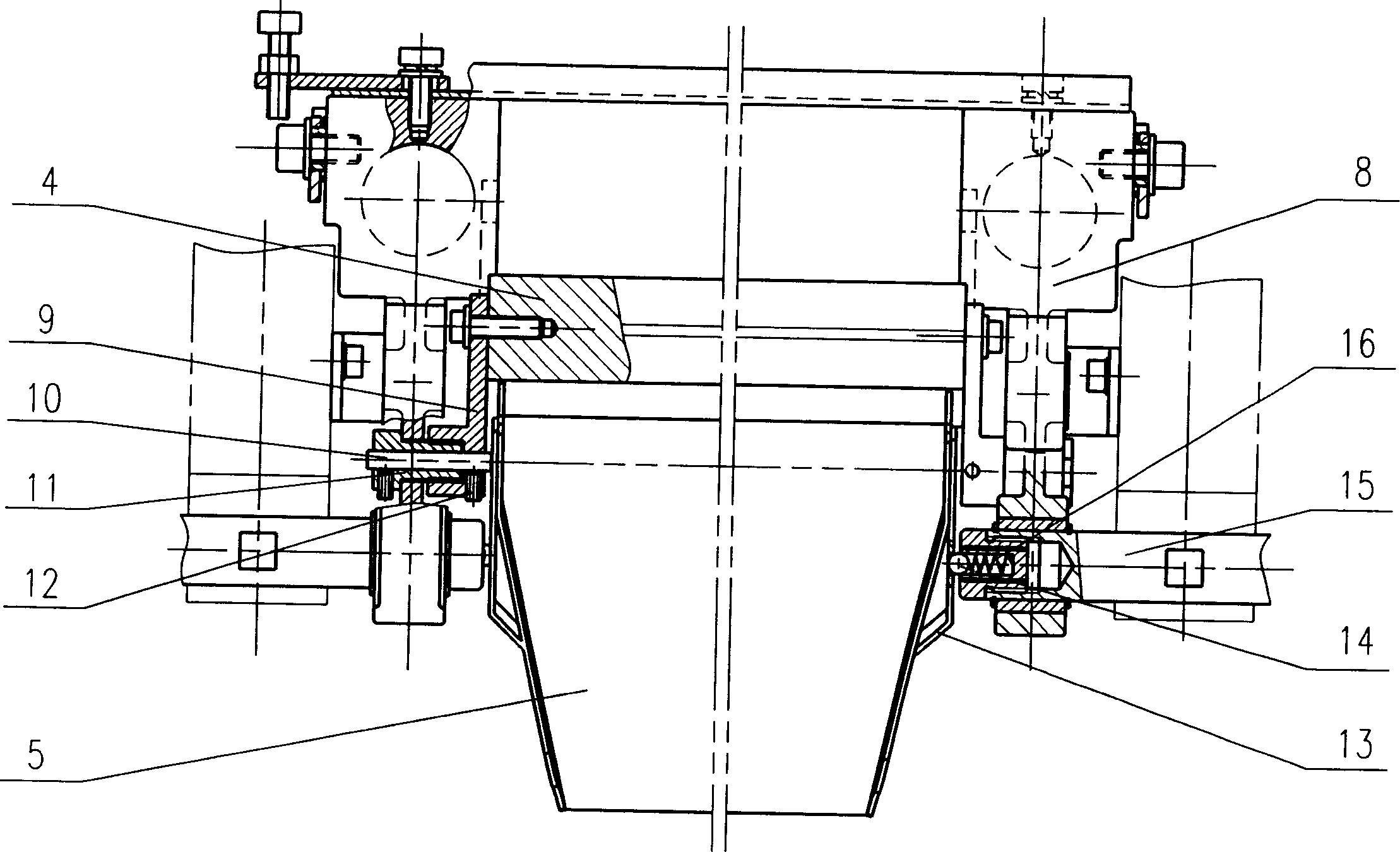

[0018] Figure 1 shows the schematic diagram of the structure of the cotton web guiding device. The combed cotton tufts are drawn into a cotton web 6 by the drafting of two pairs of separation rollers 1 and separation top rollers. In the process of regular inversion and forward rotation, the cotton web 6 is fed into the cotton guiding channel composed of the cotton guiding plate 5 and the guiding rod 4, and the cotton web entering the cotton guiding channel continues to travel along the cotton guiding plate 5 to the cotton web output The roller press roller 7 is output. The above-mentioned two separation rollers 2 are also movably placed with a cleaning fleece roller 3, the separation roller 1 on the front side and the separation roller 1 of the separation roller 2 are adjacent to the cotton guide plate 5 on the front side. The front side of the separation top roller 2 of the separation top roller 2 pair is immediately provided with a swingable guide rod 4, and the guide rod 4 is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com