Surface-modified non-metal/metal oxides coated with silicon dioxide

A surface modification, silicon dioxide technology, applied in the treatment of dyed organosilicon compounds, nanotechnology for materials and surface science, titanium compounds, etc., can solve difficult particle addition, low surface functionality intergrowth, limitations Stability and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0160] In the process for the preparation of the oxide particles used according to the invention, a base dissolved in water is added under stirring to a dispersion comprising 1-80% by weight of a metal oxide, at least one X n Si(OR) 4-n Type compounds and water; where X n Si(OR) 4-n The / metal oxide molar ratio is between 0.1 and 25 and depends on the film thickness of the silica shell; separation of the reaction product; optional rinsing; drying.

[0161] as X n Si(OR) 4-n Type compounds are preferably used as follows: X = halogen or H, R = H or a linear or branched alkyl group with 1-8 carbon atoms, n = 0-4, and if n = 4, R is not equal to H . Particular preference is given to tetraalkoxysilanes and / or oligomers thereof.

[0162] The reaction product can be isolated by filtration or centrifugation. Rinsing can be carried out with water, organic solvents or a mixture of water and organic solvents, water is preferred in the present invention.

[0163] The granules used...

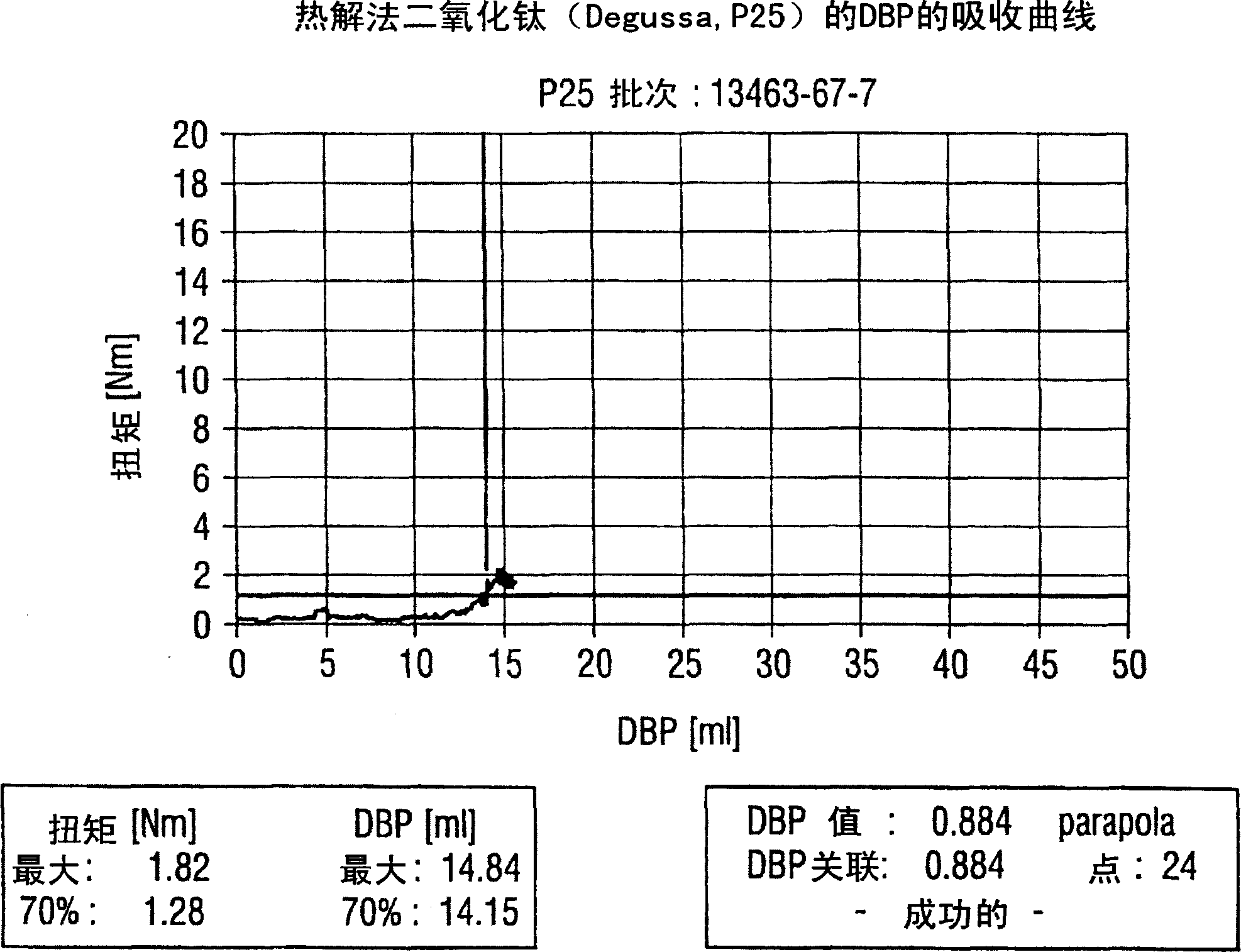

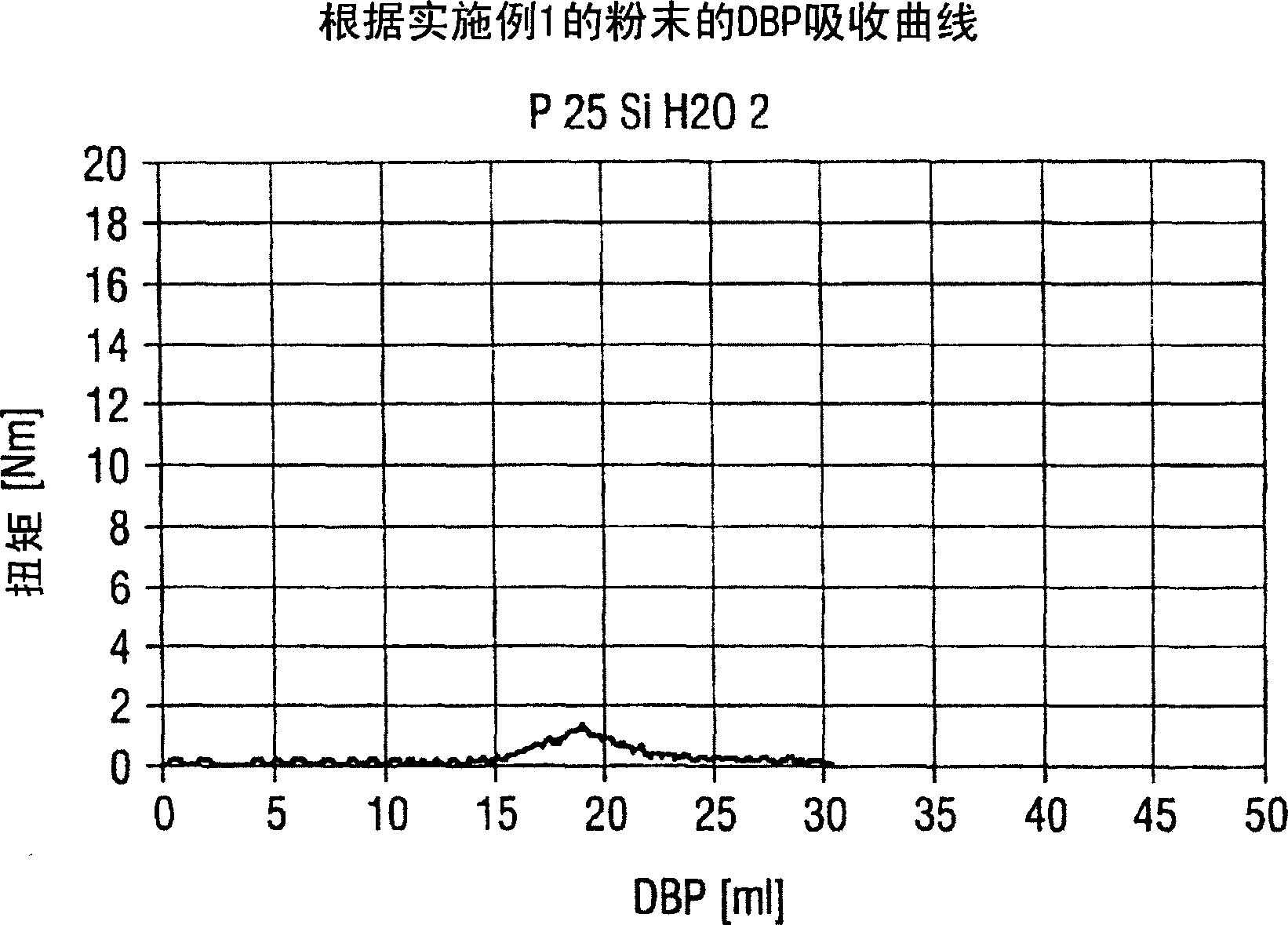

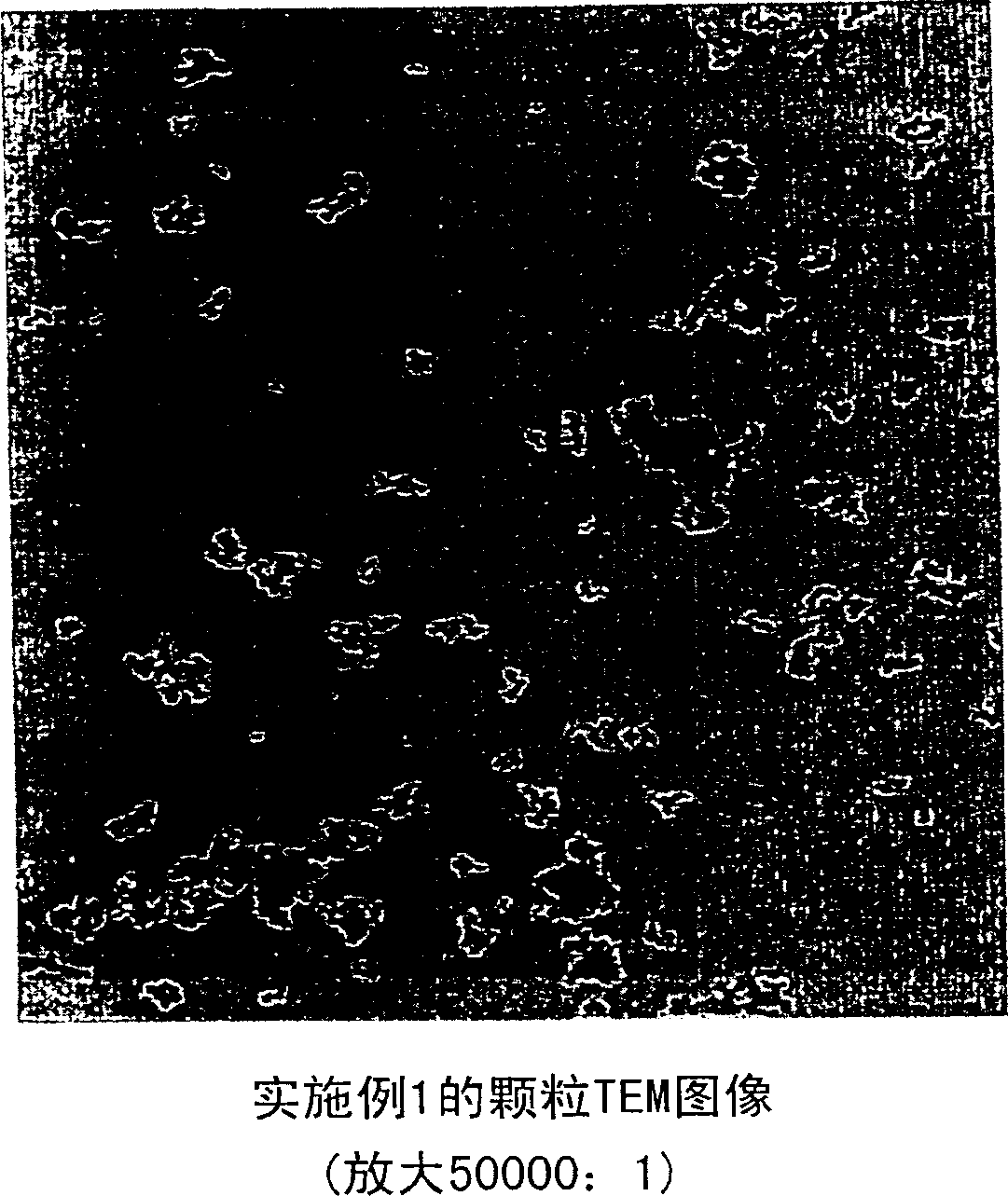

Embodiment 1

[0195] 100 g of titanium dioxide (P25 from Degussa) prepared pyrolytically by flame hydrolysis was dispersed in one liter of water. 100 ml of tetraethoxysilane was added to the solution. The mixture was stirred for 15 minutes, then 30 ml of ammonia were added. After stirring at 25°C for 2-4 hours, the product was filtered and dried.

Embodiment 2

[0197] 100 g of titanium dioxide (P25 from Degussa) prepared pyrolytically by flame hydrolysis was dispersed in one liter of water. 200 ml of tetraethoxysilane was added to the solution. The mixture was stirred for 15 minutes, then 30 ml of ammonia were added. After stirring at 25°C for 2-4 hours, the product was filtered and dried.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com