Novel quinonimine sulfur dye compositions, methods for producing them and their use for dyeing cellulose-containing material

A technology for sulfur dyes and compositions, applied in the directions of sulfur dyes, chemical instruments and methods, dyeing methods, etc., and can solve problems such as inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

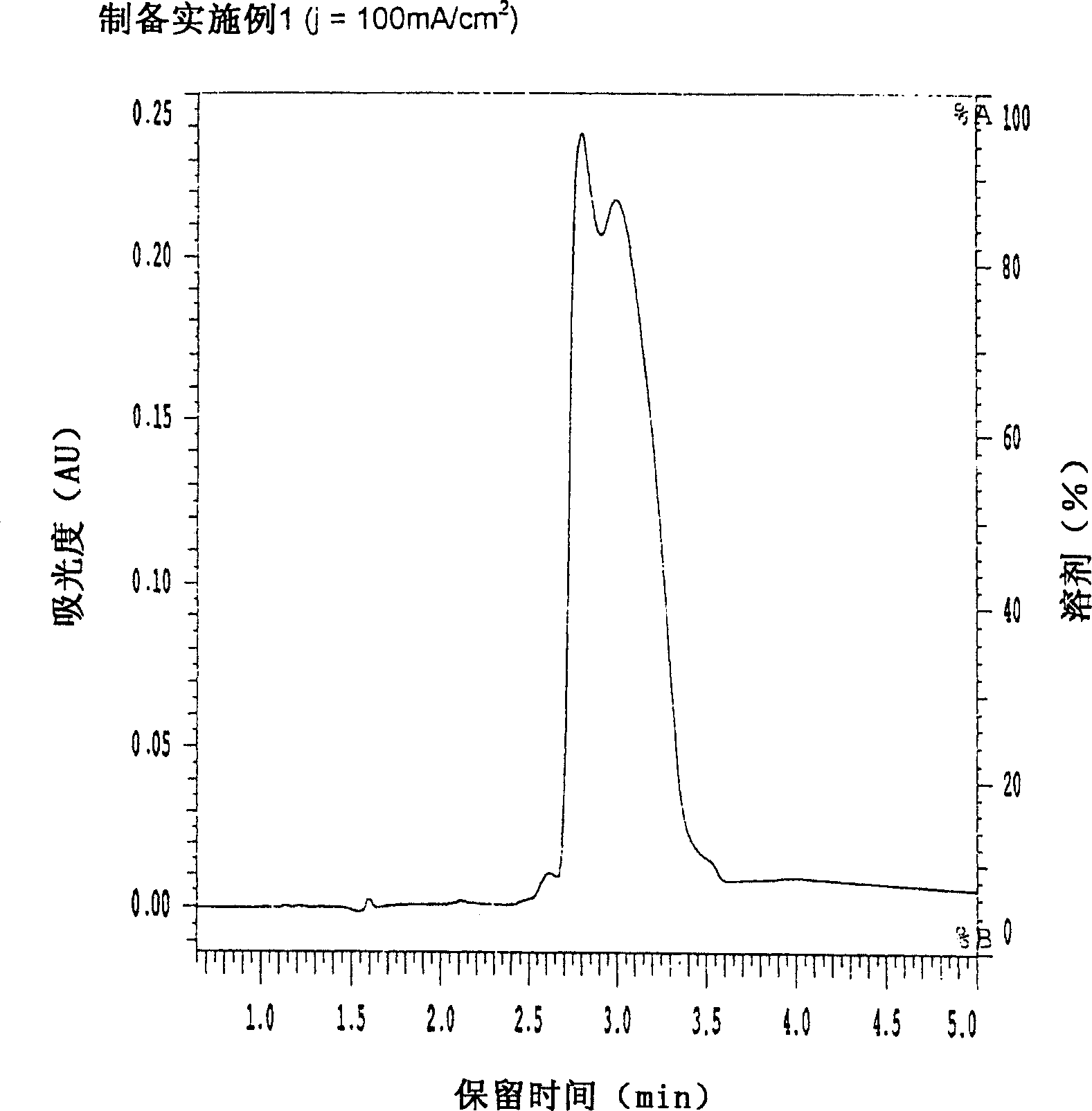

preparation Embodiment 1

[0052] Preparation Example 1 (Sample 1)

[0053] A flow-through cell separated by a cation exchange membrane (Nafion 424) was used to electrolyze the aqueous suspension of C.I. SulfurBlack 1 presscake. Start with a small amount of dye and gradually increase it during electrolysis. The reaction was started with 156.9 g of C.I. Sulfur Black 1 considered dry in 2 L of water consisting of 8 mL of 50% aqueous sodium hydroxide solution and 4 ml of Primasol NF wetting agent and continued to increase to a total volume of 5.815 L considered dry C.I.Sulfur Black 1 of up to 2271g. The anolyte used was aqueous sodium hydroxide (1 mol / l). Use 100mA / cm 2 The current density and the flow rate of 0.2m / s were electrolyzed for 3510 minutes, and the concentration of reducing equivalents that could be determined after electrolysis was 4.2, which was equivalent to a charge of 378Ah per kilogram of dye. The solution thus prepared can be used for dyeing purposes without additional addition of re...

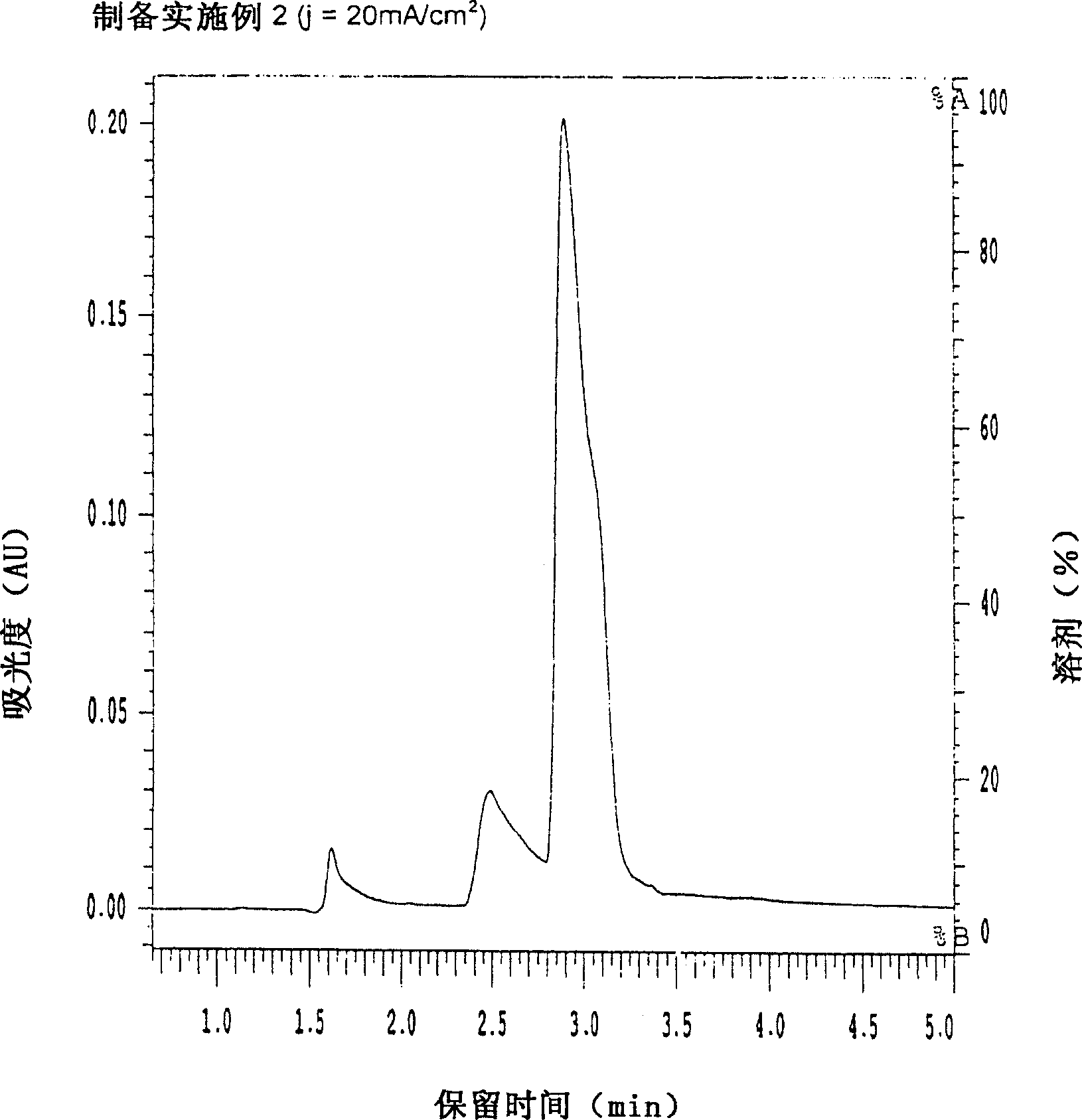

preparation Embodiment 2

[0055] Preparation Example 2 (Sample 2)

[0056] As described in DE 1906083, at 20 mA / cm using a flow-through cell separated by a cation exchange membrane (Nafion 424) 2 The current density for electrolysis of C.I.Sulfur Black 1 suspension.

[0057] The HPLC spectrum of the reaction product is shown in figure 2 middle.

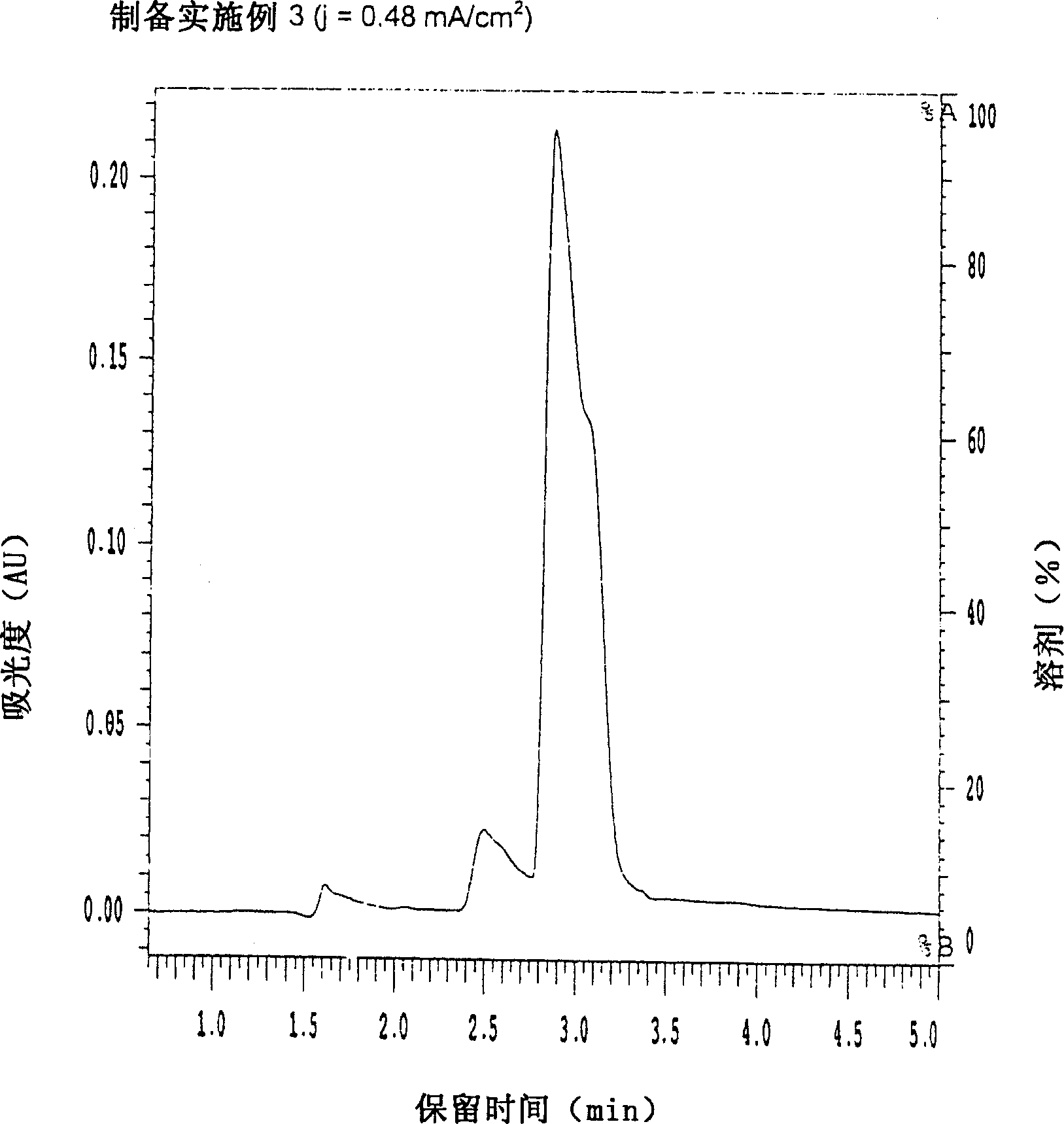

preparation Embodiment 3

[0058] Preparation Example 3 (Sample 3)

[0059] As described in DE 101222210, at 0.48 mA / cm using a flow-through cell separated by a cation exchange membrane (Nafion 424) 2 The current density for electrolysis of C.I.Sulfur Black 1 suspension.

[0060] The HPLC spectrum of the reaction product is shown in image 3 middle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com