Tab system for a metal-air electrochemical cell

A metal-air battery and tab technology, applied in battery pack components, fuel cell-type half-cells and primary-cell-type half-cells, circuits, etc., can solve the problem of low oxygen permeability, low open-circuit cell voltage, open-circuit high voltage problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

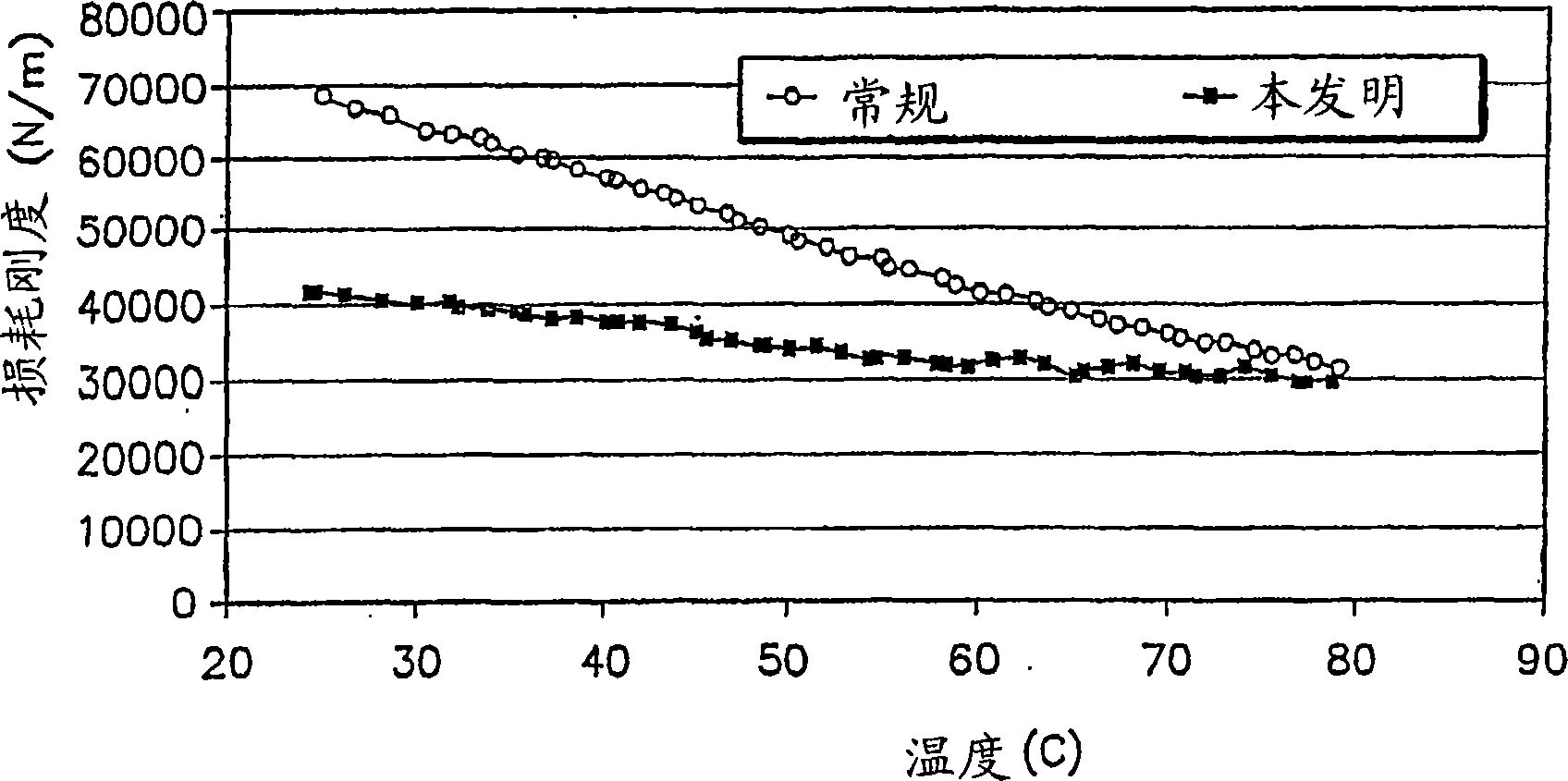

[0044] A number of samples of a conventional tab system and a sample of a tab system according to an example embodiment of the present invention were prepared. Each tab system sample was fabricated by bonding a first tape having a first polymer layer and a first adhesive layer to a second tape having a second polymer layer and a second adhesive layer. The first polymer layer, first adhesive layer and second adhesive layer were the same in all tab systems; only the first polymer layer was different.

[0045] Coating of first polymer layer and first adhesive layer for conventional tab systems available from Avery Dennison, FASSON Roll North America, Painesville, Ohio as FASSON(R) PRIMAX 350(R) 350 / R143 / 50 #SCK A polymeric tape of the binder having a polymer layer about 0.0035 inches thick (typical tensile The tensile stress is 160,000 psi and the typical tensile stress in the transverse direction is 50,000 psi). The polymer layer is coated with about 27 g / m 2 The FASSON(R) R1...

example 2

[0050] Specimens were cut from each tab system of Example 1 for burst pressure testing. Each sample was 0.386 inches long and 0.210 inches wide, and each of the two long ends had a radius of 0.105 inches.

[0051] In the burst pressure test, a tab system specimen is bonded or sealed to the surface of a test disc simulating the bottom surface of a button cell cathode can containing the air inlet, and passed from the opposite side of the disc through the The orifice applies pressure into the test specimen sealed against the orifice. The pressure is increased until the seal ruptures and the burst pressure of each specimen is the peak pressure measured before the seal ruptures.

[0052] The test discs were made of triple clad material 201 Nickel / 304 Stainless Steel / 201 Nickel available from Engineered Material Solutions Corporation and had a thickness of 0.0060 inches and a diameter of approximately 0.750 inches with a centrally located 0.0020 inch diameter orifice. The disks w...

example 3

[0057] Tab system samples were cut from each of the materials described in Example 2 for peel testing to measure the force required to remove the tab system from the cell. Previous tests have shown that test results are essentially independent of the raised design on the bottom surface of a button cell canister with air inlets; using Eveready No. AC-10 (type PR-70) Zn / air button cell (canister outer diameter is about 0.226 inches). The test coupon was placed in the center of the cell bottom during preparation and bonded or sealed to the cell bottom for testing. Store twenty batteries sealed together with each tab system at room temperature (20°C to 25°C) and 50% relative humidity, and store the cells sealed together with each tab system at a temperature of 60°C. Twenty batteries. After the specified storage time, test the peel strength of the sample. Those cells stored at a temperature of 60° C. were cooled to room temperature before testing, and tested at a temperature of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com