Gas-shield-electrode and composite bifunctional air-electrode using the same for use in metal-air batteries

一种空气电极、金属电极的技术,应用在燃料电池型的半电池和二次电池型的半电池、电池电极、电路等方向,能够解决没有双功能空气电极和二次金属-空气电池等问题,达到减少总电阻的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

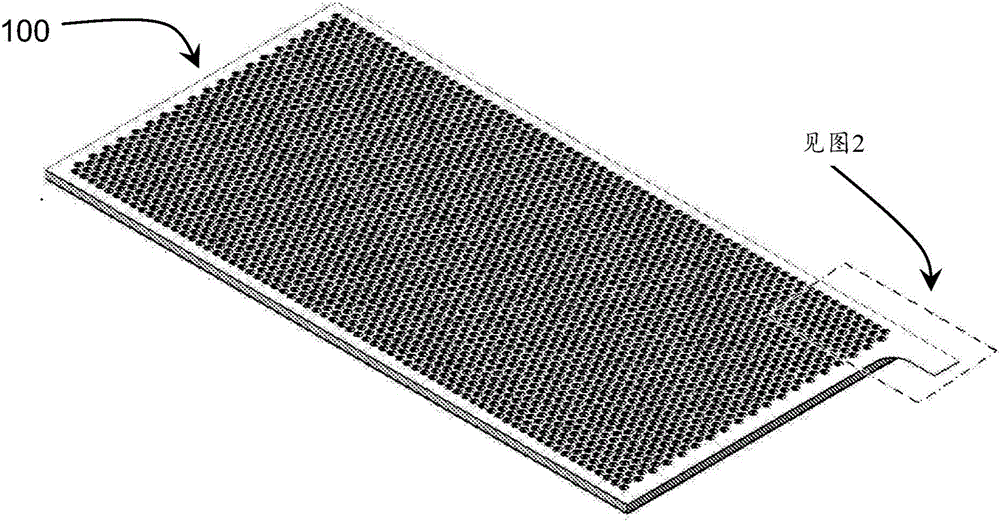

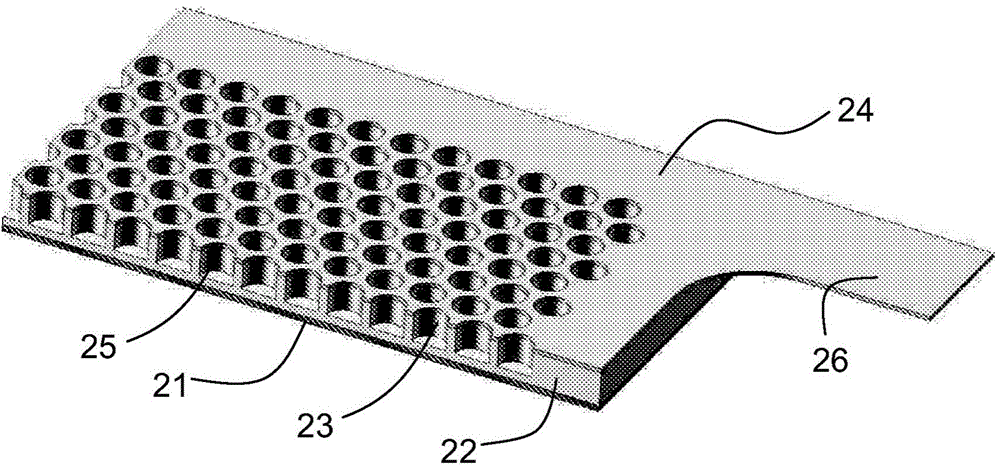

[0214] in passing figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 In the illustrated first exemplary embodiment, we utilize:

[0215] -PTFE suspension (DuPont TM PTFE TE-3893, particle size 0.05μm to 0.5μm, solid content 60%, density 1.5g / cc);

[0216] - Carbon black: Vulcan XC 72R from CABOT (BET 250m 2 / g, 30nm particle size);

[0217] - Activated carbon: SX Plus from Norit (BET 1100m 2 / g)

[0218] -MnO from Merck 2 oxygen reduction catalyst

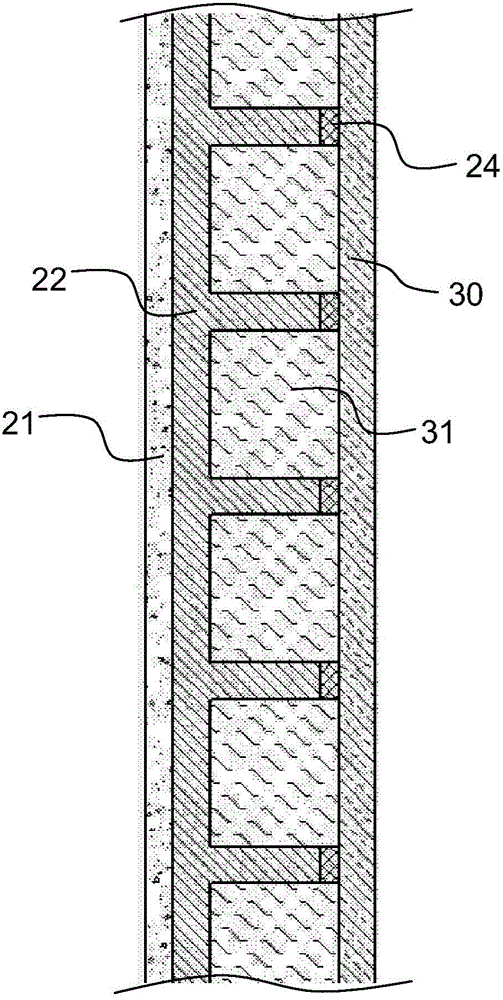

[0219] The gas diffusion layer is made of 65% carbon black + 35% PTFE, and has a thickness of 0.3mm; the hydrophilic active layer is made of 22% activated carbon + 22% MnO 2 + 46% carbon black + 10% PTFE and has a thickness of 0.6mm; the conductive layer is made of 50μm-100μm thick nickel deposits; and then the hollow space has been milled with a small end with a diameter of 0.75mm using a CNC machine This is done by machine tool drilling 0.4mm-0.5mm deep so that 3 adjacent holes form an equilater...

Embodiment 2

[0237] in passing Figure 8 with Figure 9 In the illustrated second exemplary embodiment, we utilize:

[0238] - an air electrode prepared as described for Example 1, comprising a 0.3 mm thick diffusion layer and a 0.5 mm thick active layer, but without nickel plating;

[0239] - shielding electrode comprising passages forming a 2.5mm diameter honeycomb Figure 8 The illustrated honeycomb matrix 71 is 0.8 mm thick. This honeycomb base is made of nickel with 0.2 mm thick walls and is topped by a mesh 72 made of 0.2 mm thick nickel sheet with 2 mm diameter openings. The honeycomb base and its top mesh are prepared by laser cutting.

[0240] The shield electrode is fixed to the active layer of the air electrode by some 0.2 mm thick layer of alkali resistant glue 84 such as RTV silicone rubber which also acts as an electrical insulating layer.

Embodiment 3

[0242] in passing Figure 11 , Figure 12 , Figure 13 , Figure 14 with Figure 15 In the illustrated third exemplary embodiment, we utilize:

[0243] - an air electrode prepared as described for Example 2;

[0244] - electroplating a 3 mm square pattern grid of 0.2 mm thick nickel acting as current collector 81 on the air electrode on the gas diffusion side;

[0245] - Honeycomb The honeycomb matrix is prepared by laser cutting and fixed to the active layer of the air electrode by some 0.2mm thick layer of alkali resistant glue 84 such as RTV silicone rubber which also acts as an electrical insulating layer.

[0246] After these layers are assembled, the tabs of the current collectors of the air electrode 81b are permanently connected by welding to the tabs of the electrodes of the gas shield 85b, thus resulting in a composite bifunctional air electrode that can be used with only two wires and is suitable for both cathode and anode usage in metal-air batteries.

[02...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com