Potassium sodium niobate based leadless piezoelectricity ceramic with high Qm and intermediate frequency resonator thereof

A potassium-sodium niobate-based ceramic resonator technology, which is applied to piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve the problems of no lead-free piezoelectric ceramics, very small, etc., and achieve The effect of high density and excellent resonance characteristics of ceramics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

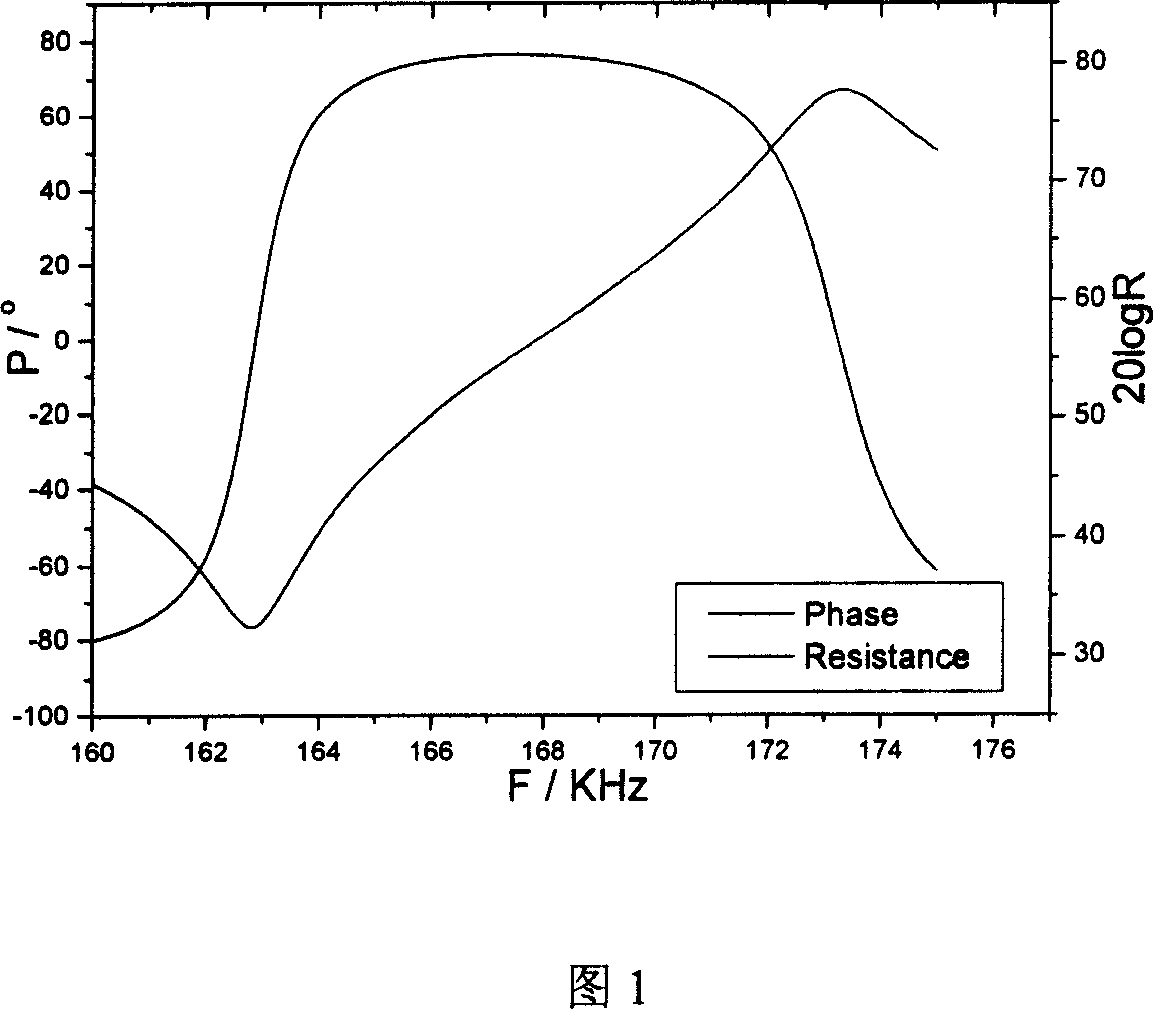

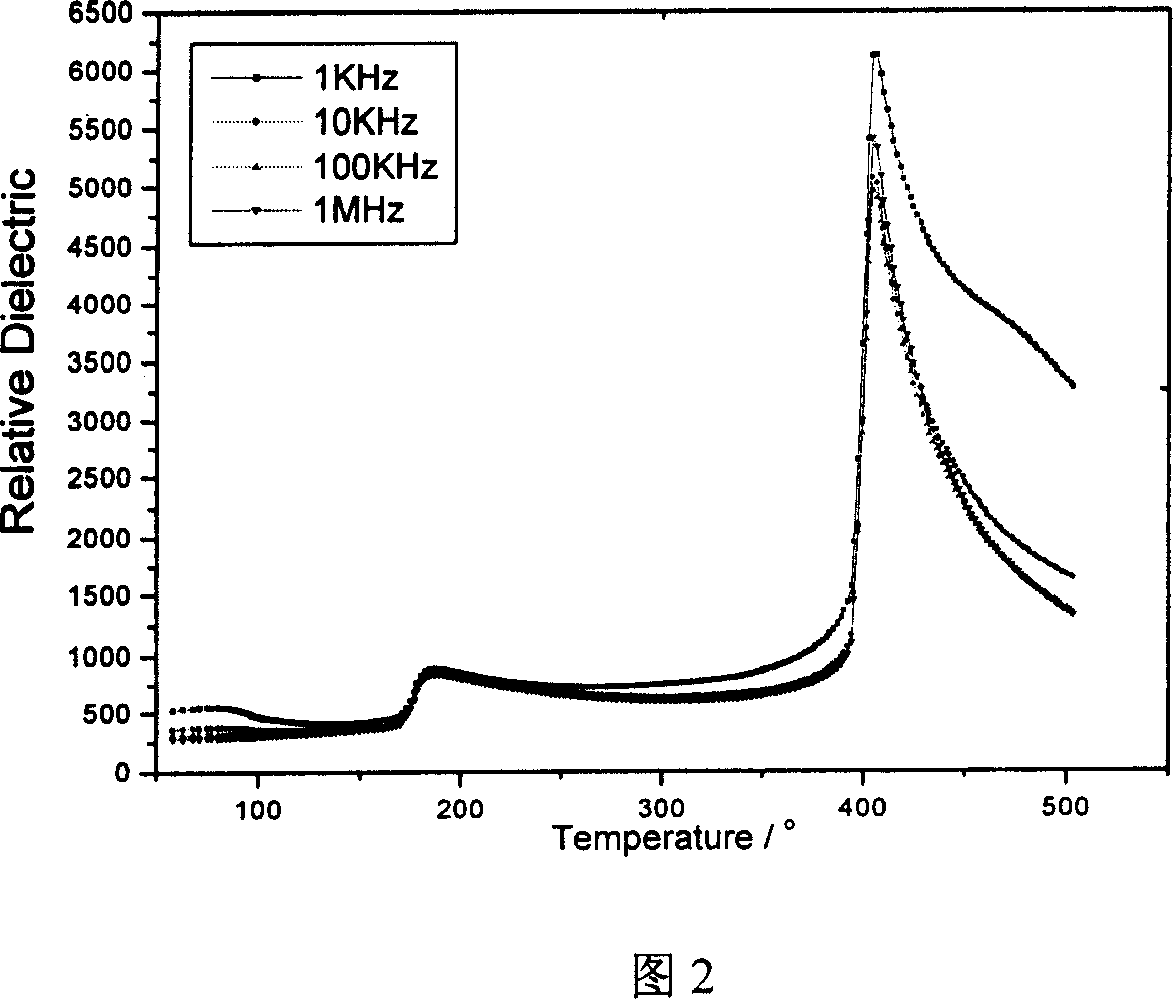

[0039] According to the stoichiometric formula (Na 0.5 K 0.505 )Nb 1.01 o 3 +0.001molCuO ingredients, weighed 132.8gNa 2 CO 3 , 176.3gK 2 CO 3 , 674.3gNb 2 o 5 , 0.524g CuO, after mixing with zirconium balls for 4 hours, put it into a corundum crucible and press it properly, and place it in a muffle furnace for pre-burning. The pre-burning process is to raise the temperature from room temperature to 850°C at a rate of 3°C / min, and keep the temperature for 4h. In order to obtain a uniform and fine powder, the block after pre-burning at 850°C for 4 hours was crushed and passed through a 20-mesh sieve, and then vibrated with zirconium balls for 7 hours; Granulate 12% PVA powder and pass through a 60-mesh sieve; the granulated powder is pressed into a disc with a diameter of 23mm and a thickness of 1.2mm, and the pressure is 20MPa, and the pressure is maintained for 30s; After fully debinding, the blank is sintered at 1085°C for 2 hours. The surface of the sintered sampl...

Embodiment 2

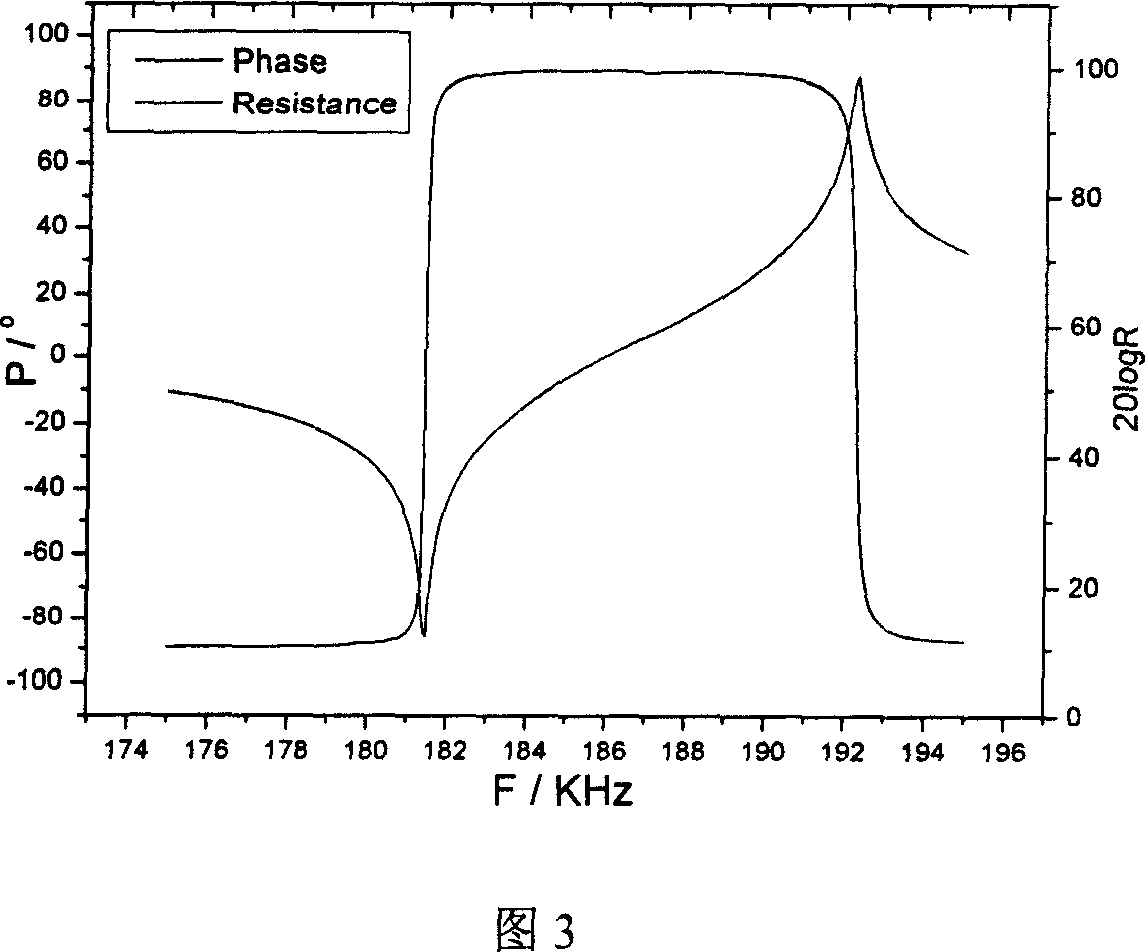

[0041] According to the stoichiometric formula (Na 0.5 K 0.516 )Nb 1.032 o 3 +0.004molCuO ingredients, weighed 132.8gNa 2 CO 3 , 180.1gK 2 CO 3 , 688.7gNb 2 o 5 , 1.605g CuO, after mixing with zirconium balls for 4 hours, put it into a corundum crucible and press it properly, and place it in a muffle furnace for pre-burning. The pre-firing was raised from room temperature to 850°C at a rate of 3°C / min, and kept for 4 hours. In order to obtain a uniform and fine powder, the block after pre-burning at 850°C for 4 hours was crushed and passed through a 20-mesh sieve, and then vibrated with zirconium balls for 7 hours; Granulate 12% PVA powder and pass through a 60-mesh sieve; the granulated powder is pressed into a disc with a diameter of 23mm and a thickness of 1.2mm at a pressure of 20MPa and hold for 30s. After the formed green body is fully degummed, it is sintered at 1075 ° C for 2 hours; the surface of the sintered sample is smooth and smooth, and there is a crisp...

Embodiment 3

[0043] According to the stoichiometric formula (Na 0.5 K 0.522 )Nb 1.043 o 3 +0.005molCuO ingredients, weighed 132.8gNa 2 CO 3 , 182gK 2 CO 3 , 696.1gNb 2 o 5 , 2.162g CuO, after mixing with zirconium balls for 4 hours, put it into a corundum crucible and press it properly, and place it in a muffle furnace for pre-burning. The pre-firing was raised from room temperature to 850°C at a rate of 3°C / min, and kept for 4 hours. In order to obtain a uniform and fine powder, the block after pre-burning at 850°C for 4 hours was crushed and passed through a 20-mesh sieve, and then vibrated with zirconium balls for 7 hours; Granulate 12% PVA powder and pass through a 60-mesh sieve; the granulated powder is pressed into a disc with a diameter of 23mm and a thickness of 1.2mm at a pressure of 20MPa and hold for 30s. After the formed green body is fully degummed, it is sintered at 1075°C for 2 hours; the surface of the sintered ceramic sample is smooth and smooth, and there is a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com