Polyester fiber enhanced breadth and high-performance polyvinyl chloride composite material and preparation thereof

A composite material and polyvinyl chloride technology, applied in textiles and papermaking, can solve the problems of low production efficiency, poor self-cleaning, and cumbersome processing, and achieve the effect of high production efficiency and strong production capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0034] Example 1: The required production quantity is 900g / m2m 2 , width 3.80M, fire retardant M2 (NFP 92503) blackout white tent;

example 2

[0035] Example 2: The required production quantity is 770g / m2m 2 , width 3.60M, blue swimming pool cloth;

example 3

[0036] Example 3: The required production quantity is 1150g / m2m 2 , width 3.40M, red inflatable cloth.

[0037] Step 1 Mixing pulp

[0038] Add DINP, Ba / Zn liquid stabilizer to the barrel, then add resin, CaCO3, flame retardant, etc. under stirring, and stir at high speed for 10 minutes to complete the premixing. After that, it is ground with a three-roll mill, filtered and stored in another clean bucket. Then according to the required color of the product, add the color paste soaked and ground with plasticizer, stir at high speed to make the system evenly dispersed. Finally vacuum stirring and defoaming for 20 minutes, the batching is finished.

[0039] Step 2 Coating

[0040] Produced according to the process indicators in Table 2.

[0041] Step 3 surface treatment

[0042] The temperature of the oven is 140°C, and the amount of sizing (moisture) is 20-30g / m 2

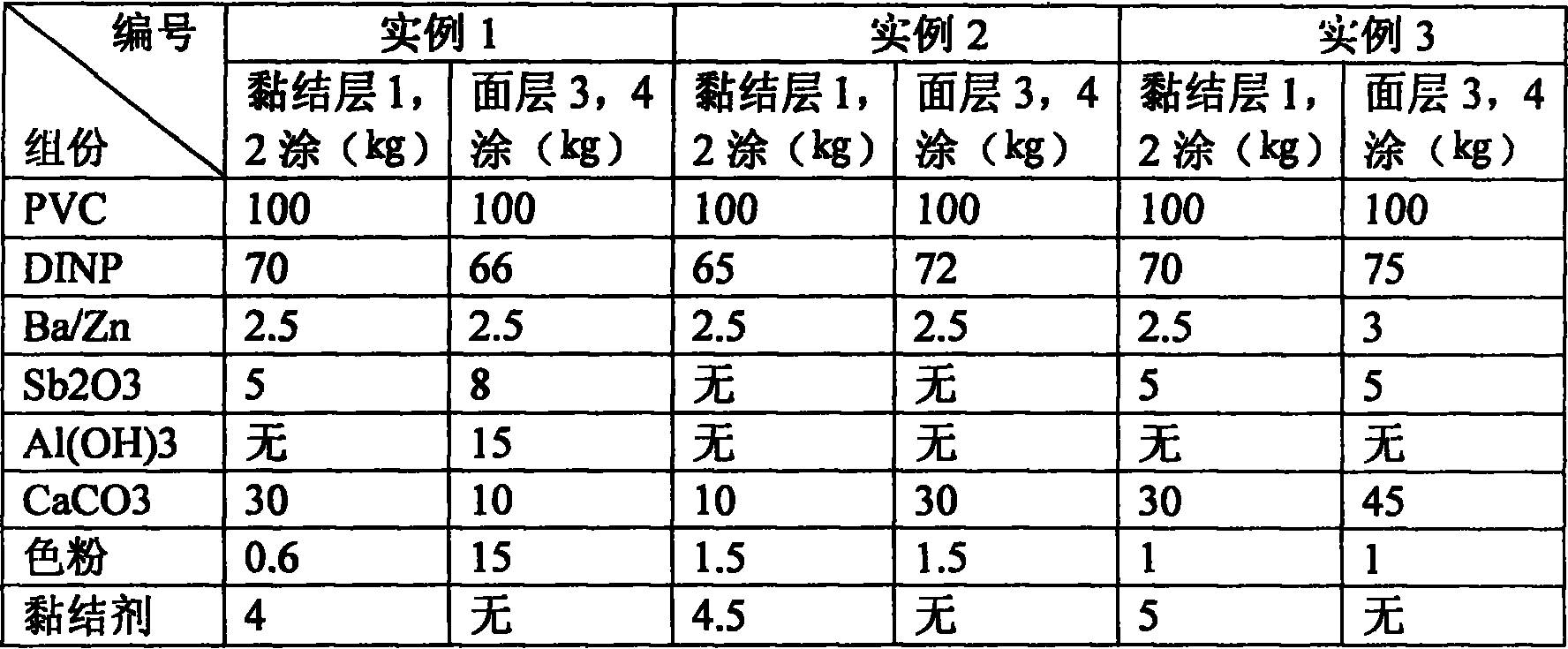

[0043] Formulation of table 1 example 1-3

[0044]

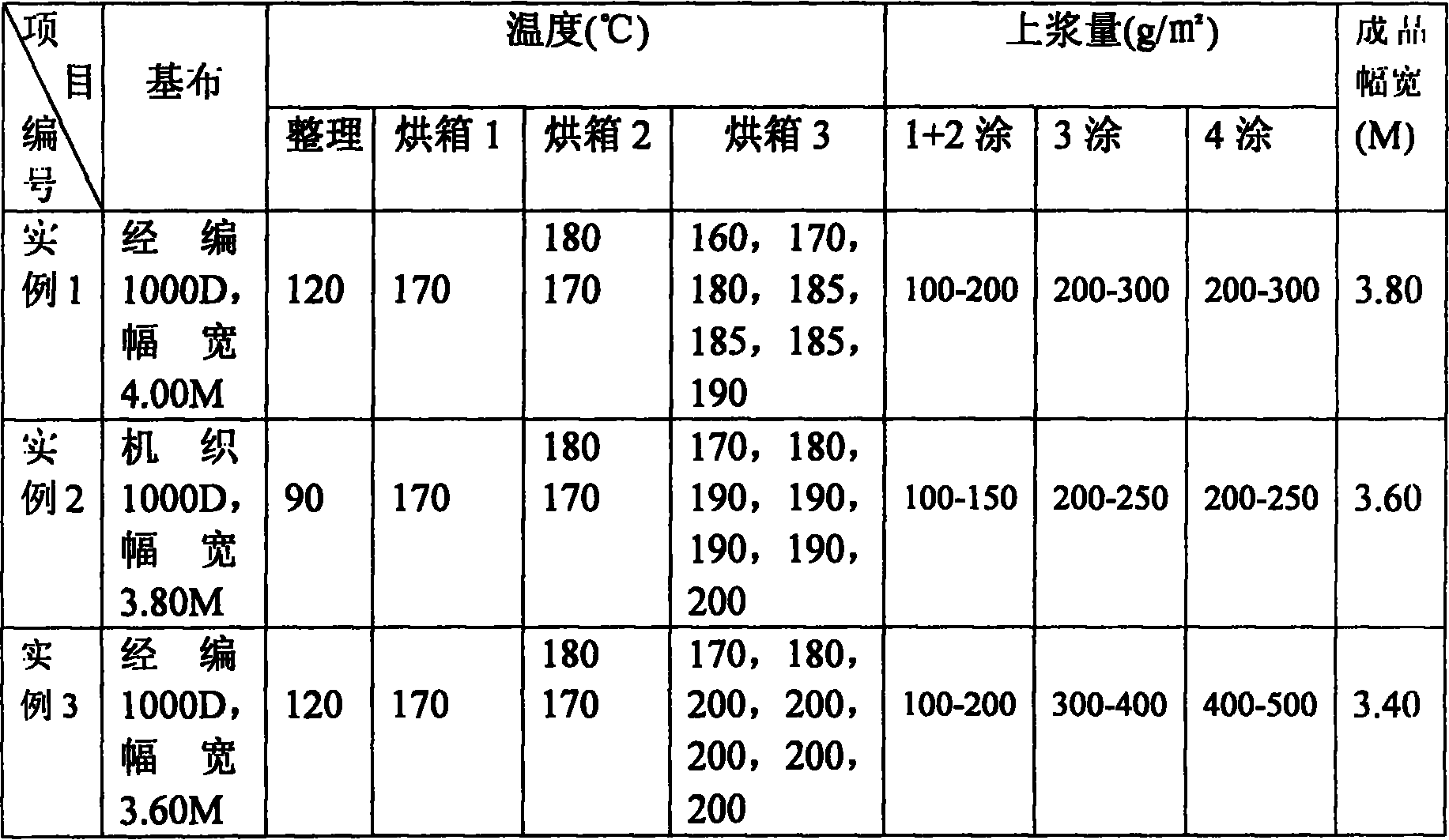

[0045] The coating process condition of table 2 e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com