Method and equipment for measuring fluid viscosity of capillary pipeline

A technology of fluid viscosity and measuring device, which is applied in the field of fluid viscosity measurement and device in capillary pipeline, can solve the problem of inability to realize online rapid detection of fluid viscosity, difficulty in heating and temperature control of sample needle, and inability to realize online measurement of Newtonian fluid viscosity measurement, etc. problems, to obtain the test results in real time, save the liquid for testing, and achieve accurate and reliable data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for measuring the fluid viscosity of a capillary pipeline, which uses a fluid viscosity measuring device for adding a sample capillary pipeline to collect data, uses a solution processor to process the collected data, and outputs the viscosity data of the measured fluid;

[0027] a. Inject the reference liquid into the reference liquid sample cup, put the measured liquid into the measured liquid sample cup, make the fluid viscosity measuring device in the environment of 20 ° C ~ 40 ° C, and make all the sample cups The temperature of the liquid should be uniform; a simple measure is to place the sample cup in the environment for 20 to 40 minutes after injecting the liquid; or use a ventilation device to generate a circulating air flow to make the liquid temperature in all the sample cups uniform;

[0028] b. Start the fluid viscosity measuring device, insert the sampling needle into the reference liquid in the reference liquid sample cup, use the sampling needle...

Embodiment 2

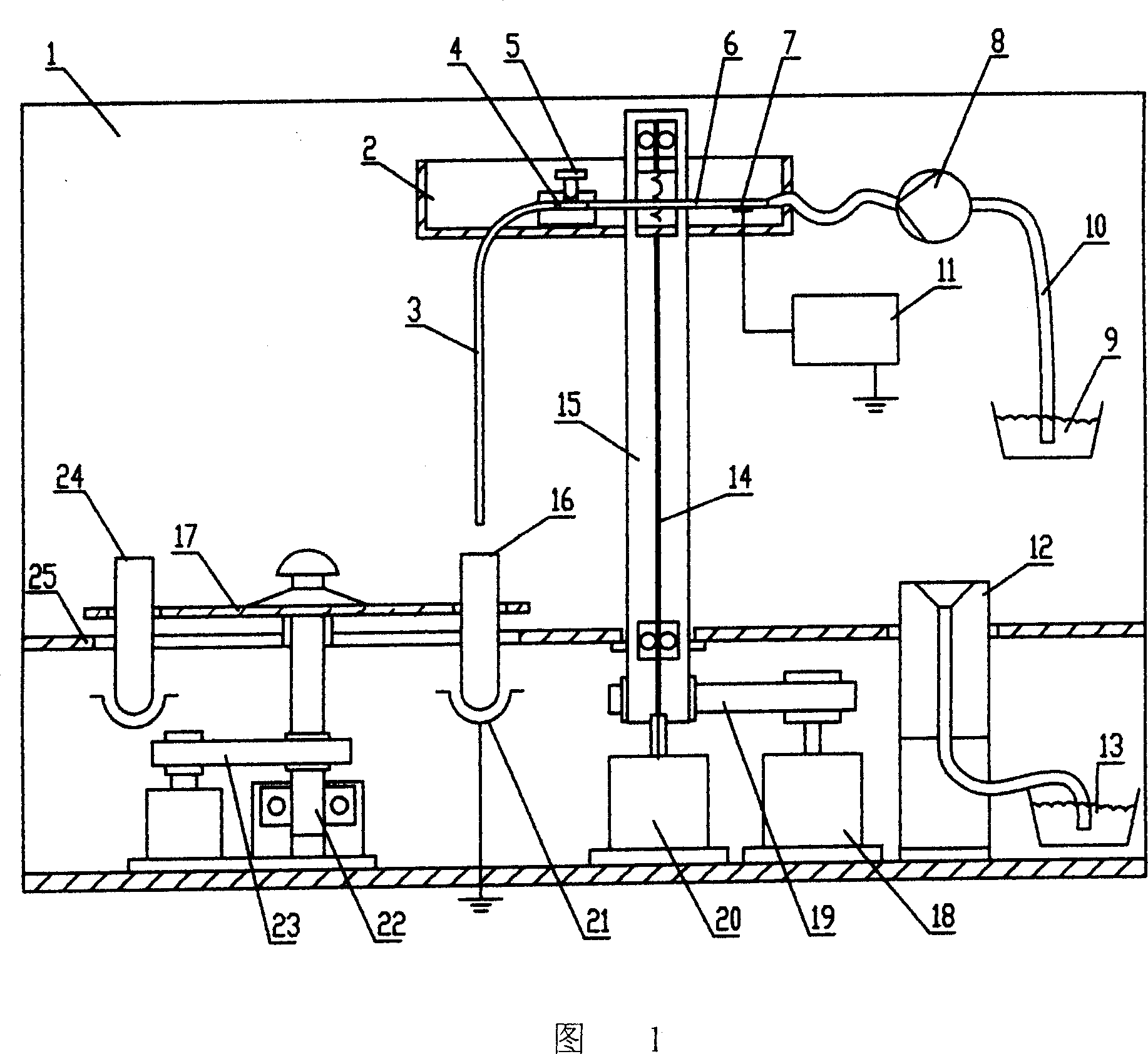

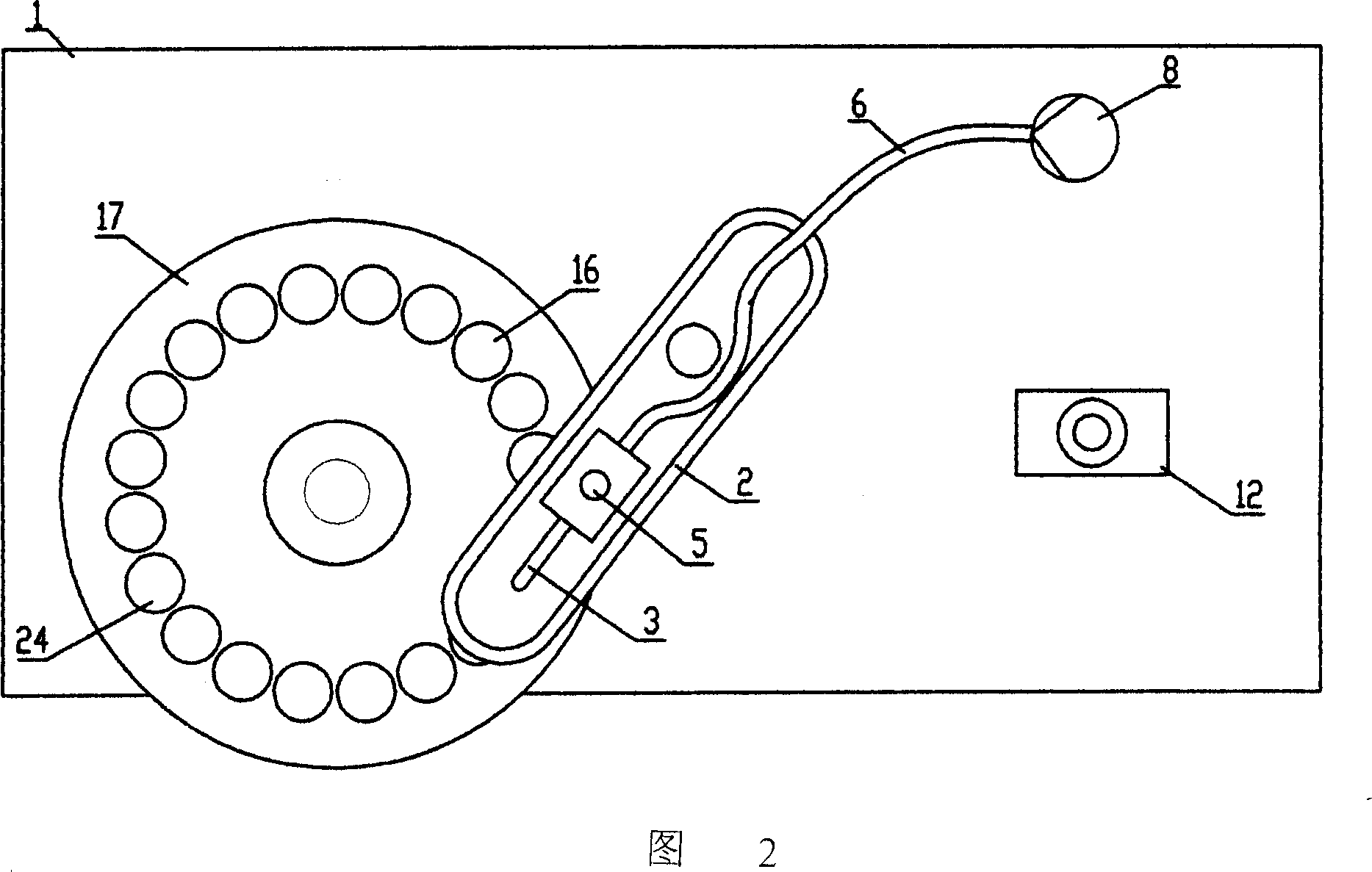

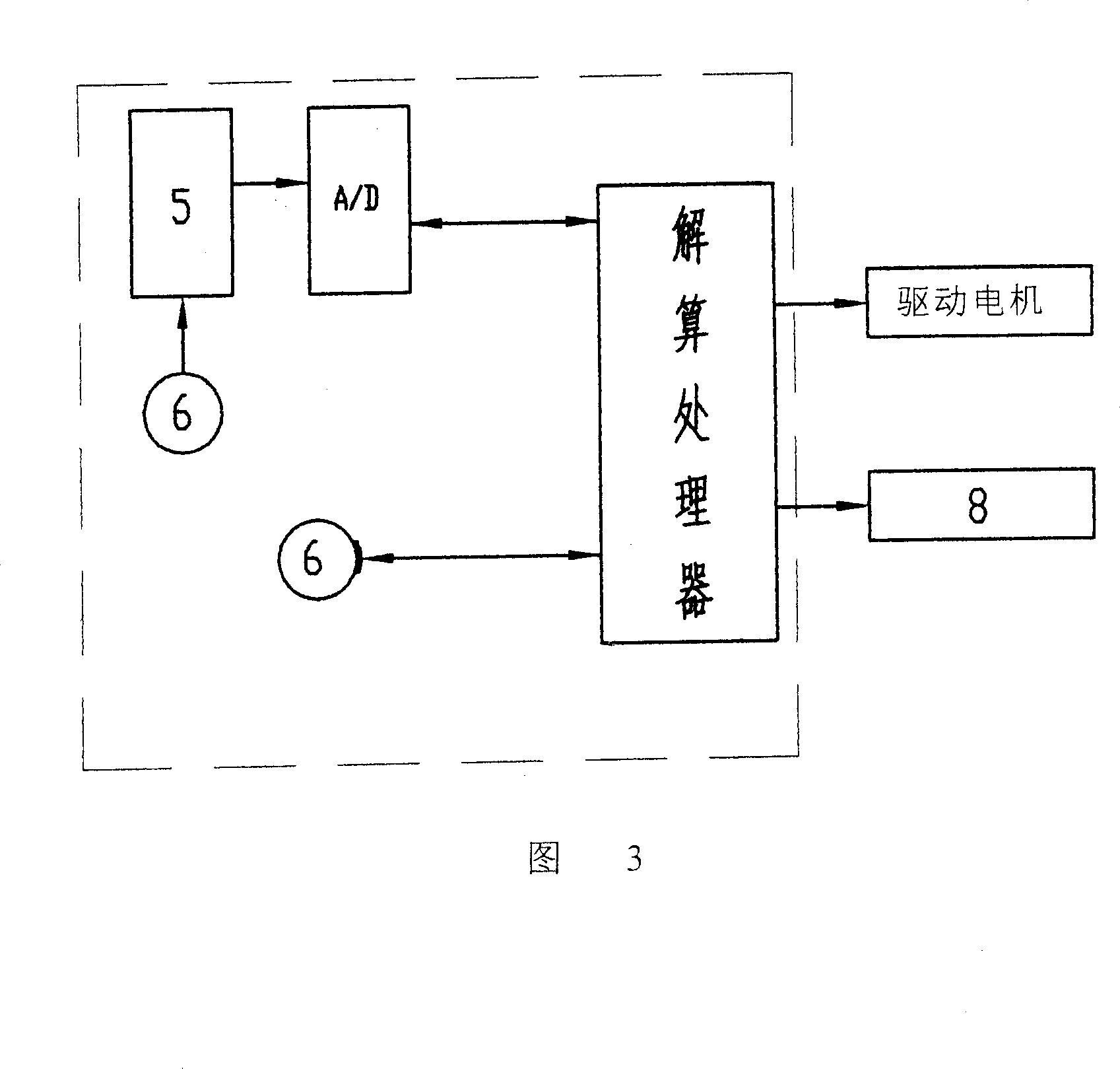

[0046] Referring to Fig. 1, Fig. 2, Fig. 3, the fluid viscosity measuring device of the present invention has a frame 1, and this frame adopts engineering plastics to make, and this frame is provided with sample needle mounting frame 2, and this mounting frame can A conventional swing arm lifting mounting bracket is adopted, and a vertical capillary sampling needle 3 is fixed on the sampling needle mounting bracket, and the sampling needle communicates with a sampling pump 8 through a sampling pipeline 6, This forms a sample filling capillary. A pressure sensor 5 is arranged on the sampling needle body or the sampling pipeline, and the pressure sensor is electrically connected to a solving processor through a data line, and the solving processor is connected to the sampling pump through a control line. The input end is electrically connected, and a sample cup holder 17 is arranged under the capillary-type sampling needle, and a reference liquid sample cup 24 and a measured liq...

Embodiment 3

[0054] In an embodiment of the present invention, the sample cup holder is a linearly transposed sample tray, and the mounting frame for the sampling needle is a linearly movable mounting frame. The linear transposition sample disk reciprocates along the Y axis, and the sample needle installation frame reciprocates along the X axis, and can be raised and lowered. The sample disk is provided with a reference liquid sample cup and a measured liquid sample cup.

[0055] Fig. 4, Fig. 5 have shown the specific structure of embodiment, have a frame 201, are provided with sample needle mounting frame 212 on this frame, this mounting frame is linear movable type mounting frame, can drive motor 217, transmission wire Driven by the bar 214, the guide column 215 moves up and down along the Z direction. The drive motor, transmission screw, and Z guide column are installed on a Z seat plate 227, and the Z seat plate is installed on the X seat plate 213 through the X guide rail 203, the bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com