Device for filling tubes, containers and the like with bulk materials

A loose material, test tube technology, used in loading/unloading, transportation and packaging, chemical instruments and methods, etc., can solve the problem of wasting time, and achieve the effect of saving a lot of cost and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

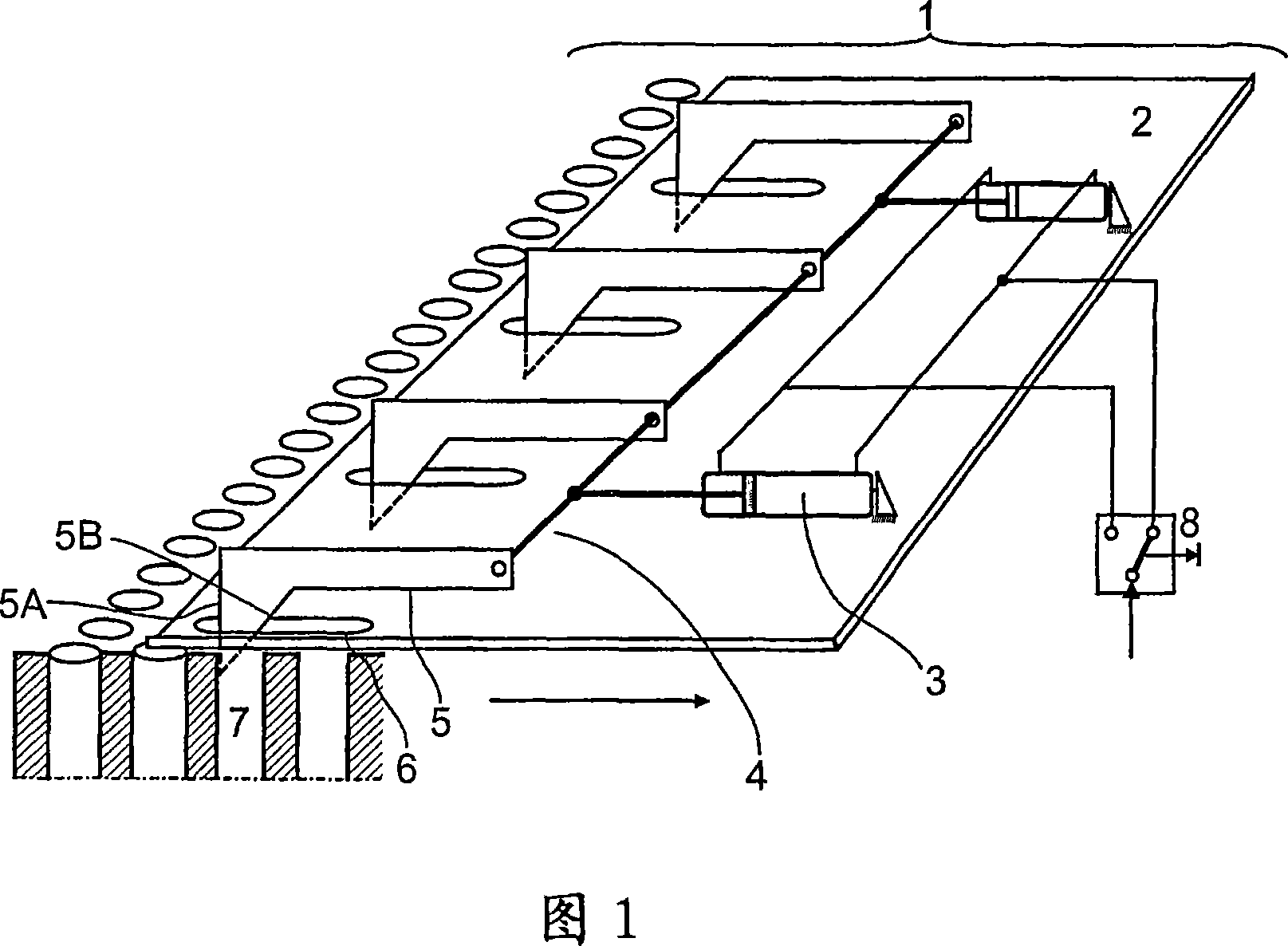

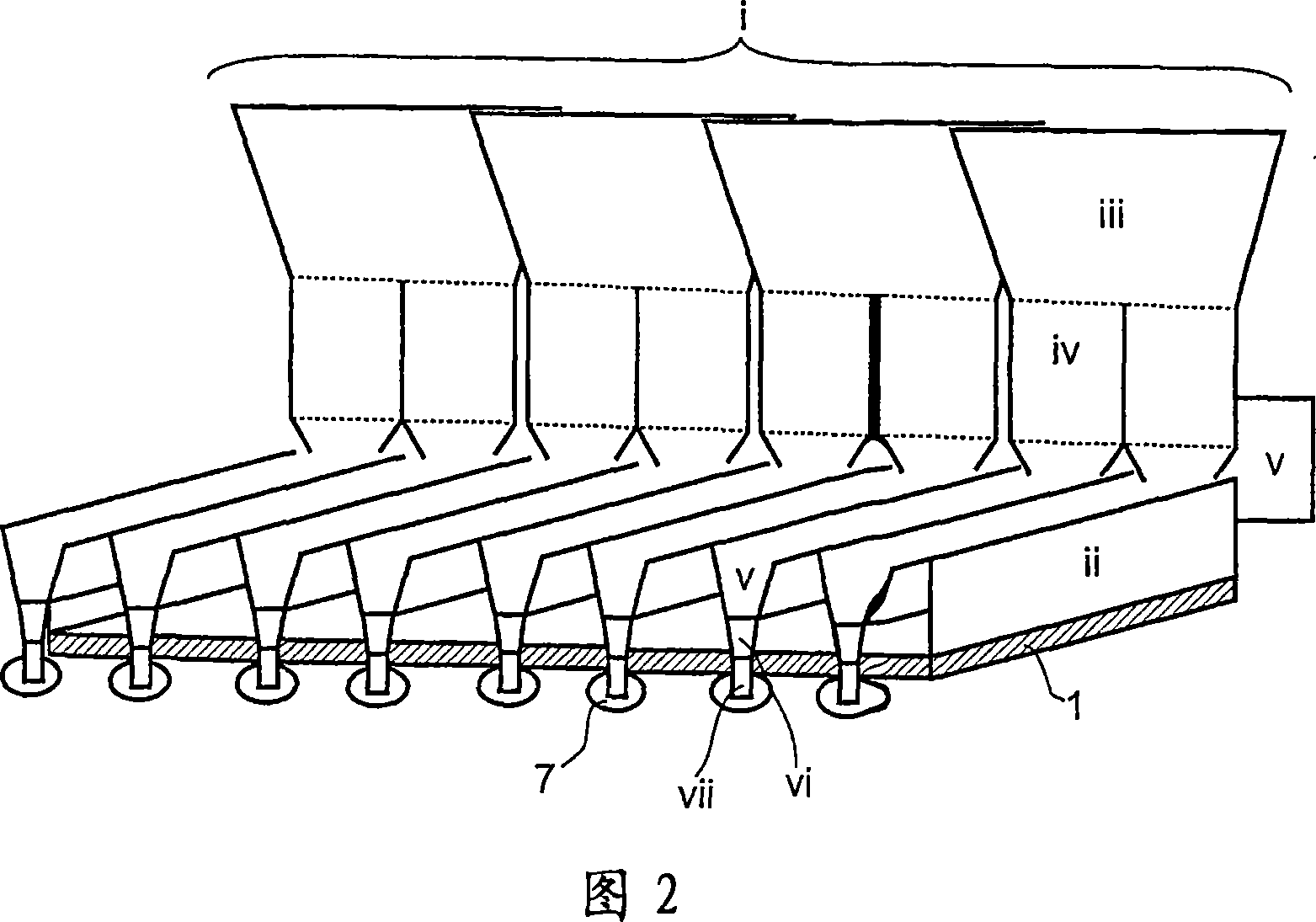

[0031]The conveying device 1 generally comprises a base plate 2 on which two piston-cylinder units 3 are fixed. The push rod of the piston-cylinder unit is connected to the delivery claw 5 via the connecting rod 4 . The free ends of the transport claws 5 protrude through openings 6 in the bottom plate into test tubes 7 of the shell and tube reactor. The transport claw 5 has a straight side 5A and a beveled side 5B. The repositioning of the delivery means is triggered by means of the pneumatic button 8 . When the button is pressed, the jaw 5 is pulled back from its rest position by means of the push rod of the piston-cylinder unit 3 . Due to (the presence of) the beveled edge 5B, this movement of the transport jaw does not stop at the tube edge; the transport jaw slides over the test tube edge and the free jaw falls into the next column of test tubes. When button 8 is pressed again, cylinder 3 moves in reverse. However, due to (the presence of) the straight edge 5A, the cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com