Carbon nanotube preparing apparatus and process

A carbon nanotube and preparation device technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of poor alignment of carbon nanotubes, affecting the upright growth of carbon nanotubes, etc. , to achieve the effect of mass production and increasing growth area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

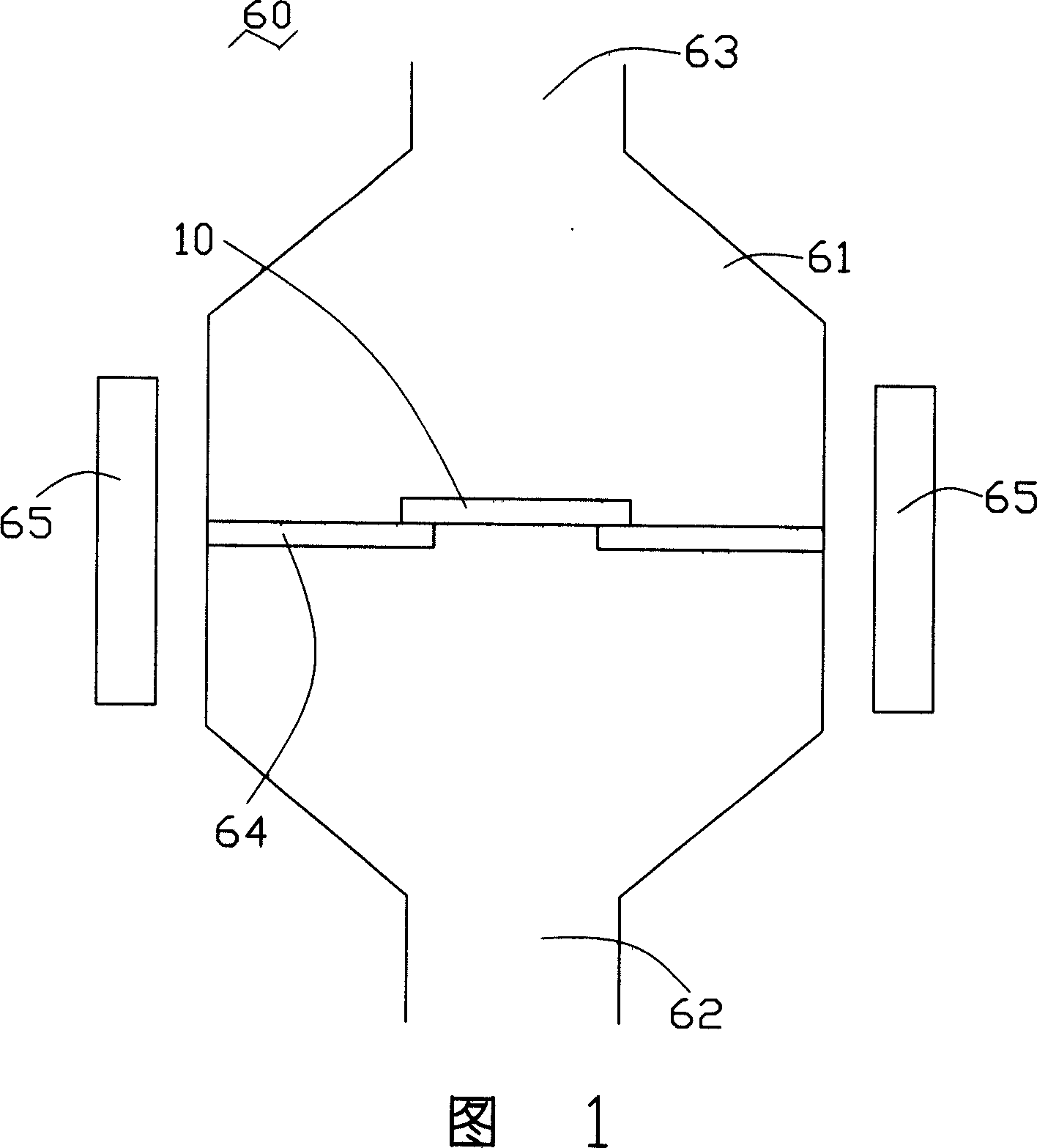

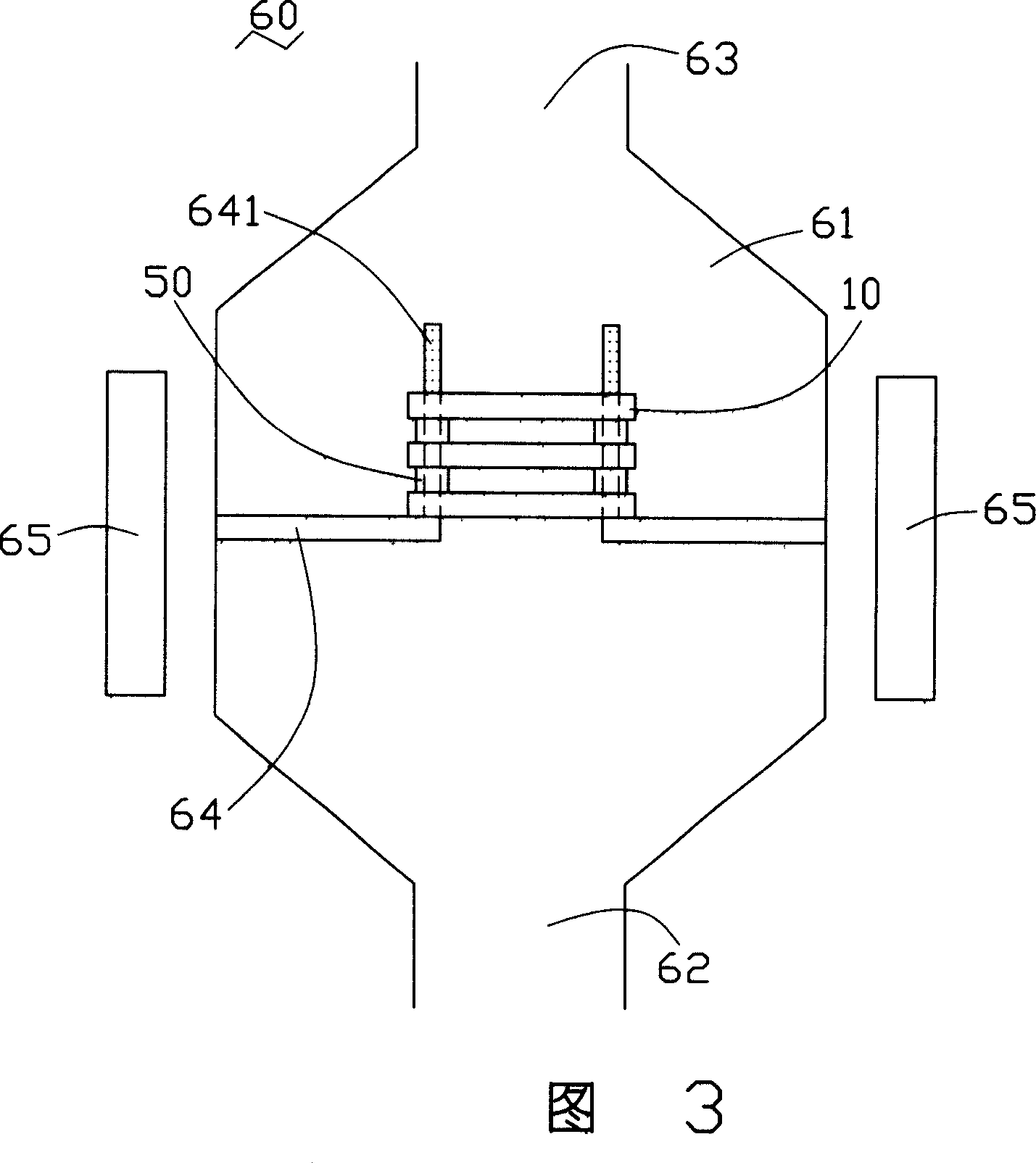

[0023] Referring to FIG. 1 , a carbon nanotube preparation device 60 provided by the first embodiment of the present invention includes: a reaction chamber 61 , a heating device 65 and a substrate 10 .

[0024] The reaction chamber 61 also includes an air inlet 62, an exhaust port 63 and a substrate carrying device 64; Into a carbon source gas; the exhaust port 63, which is located at the top of the reaction chamber 61 and is opposite to the air inlet 62, and it cooperates with the air inlet 62 can make the carbon source gas flow direction and the growth of carbon nanotubes The directions are parallel; the substrate carrying device 64 is arranged in the reaction chamber 61 and is located between the air inlet 62 and the air outlet 63 .

[0025] The heating device 65 is arranged around the reaction chamber 61 for heating the reaction chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com