Oil-free dry multi-motor head stock and foot end drafting drive system for ring spinning frame

A technology of transmission device and spinning frame, which is applied in the direction of spinning machine, continuous winding spinning machine, textile and paper making, etc. It can solve the problems of broken end and high cost of servo system, so as to expand the suitable range of spinning and simplify the The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

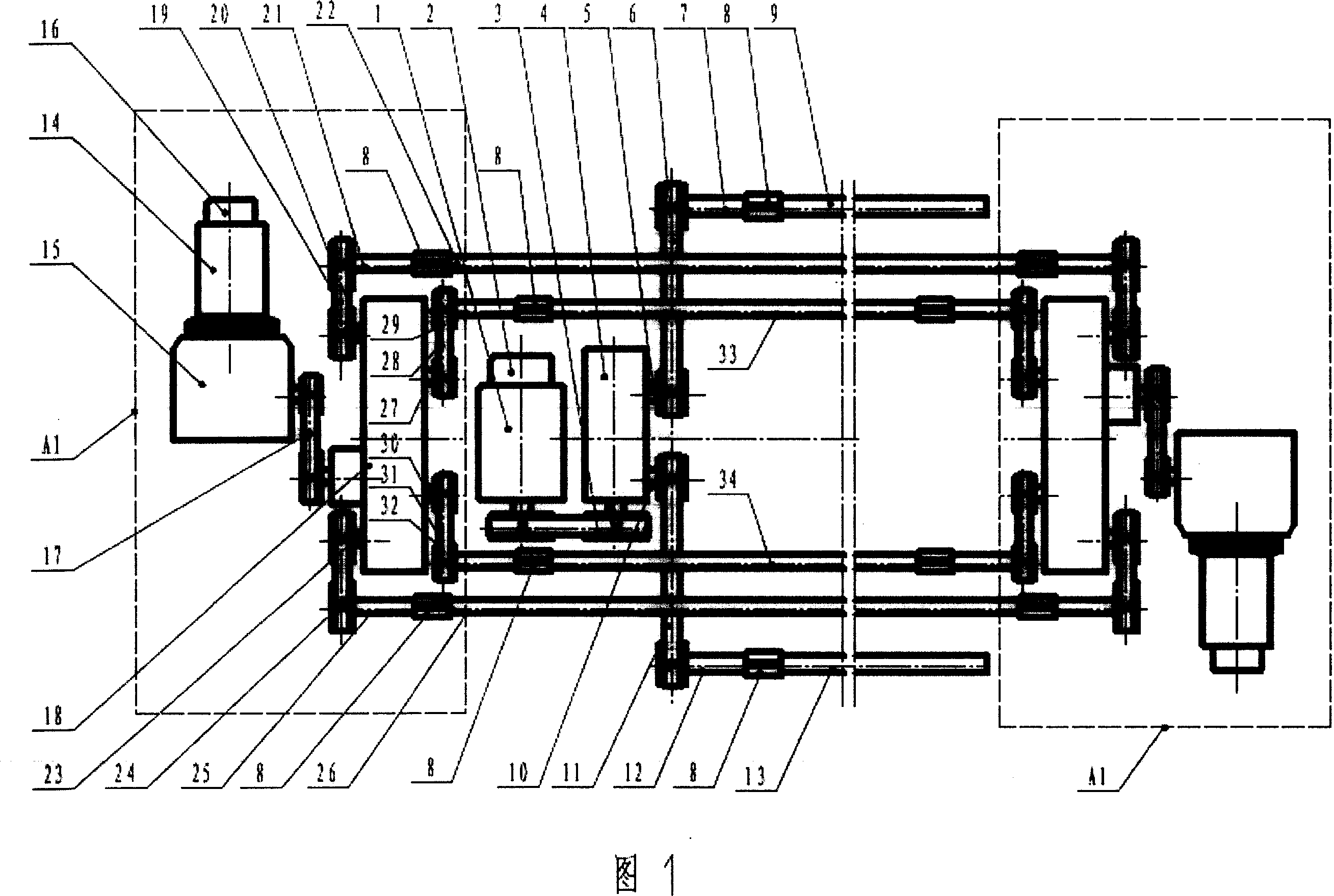

[0009] The structure shown in Figure 1 shows the transmission mode and transmission route of the multi-motor drafting transmission device of the ring spinning locomotive head and rear. When working, the first three-phase permanent magnet synchronous motor 1 drives the front roller to decelerate through the first synchronous belt 3 Box 4, the left output shaft 5 of the front roller reduction box 4 drives the left front roller transmission shaft 7 through the second synchronous belt 6, the left front roller transmission shaft 7 is connected with the left front roller 8 through a coupling 8, the right output of the front roller reduction box 4 The shaft 10 drives the right front roller transmission shaft 12 through the third synchronous belt 11, and the right front roller transmission shaft 12 is connected with the right front roller 13 through the coupling 8; the second three-phase permanent magnet synchronous motor 14 drives the middle and rear rollers through the fourth synchron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com