Helical rotor for high density hydraulic pulper

A hydraulic pulper and screw technology, applied in the field of pulping and papermaking, can solve the problems of difficulty in ensuring processing accuracy, failure to achieve pulping effect, complex unfolding shape, etc., achieving simple and symmetrical structure, good disintegration flow field, Easy to create effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings.

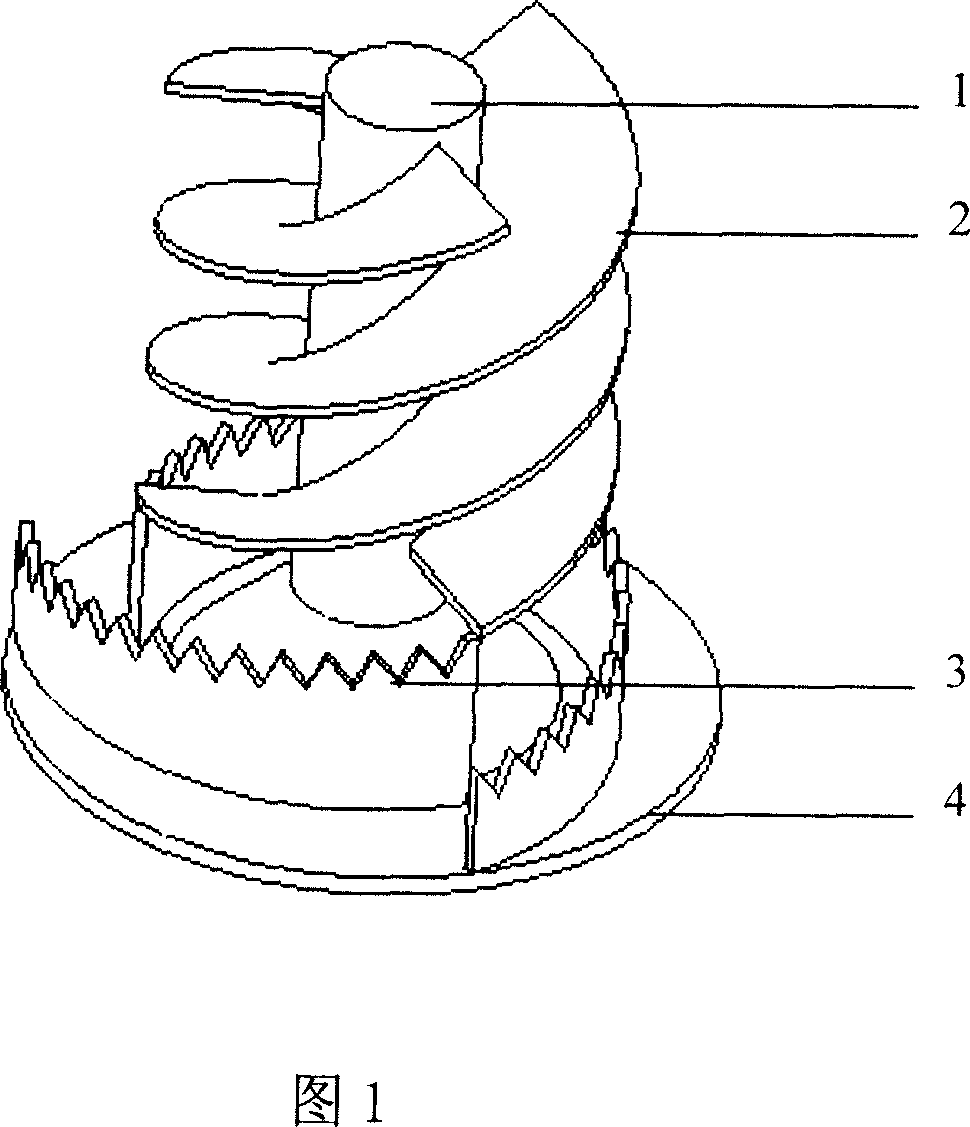

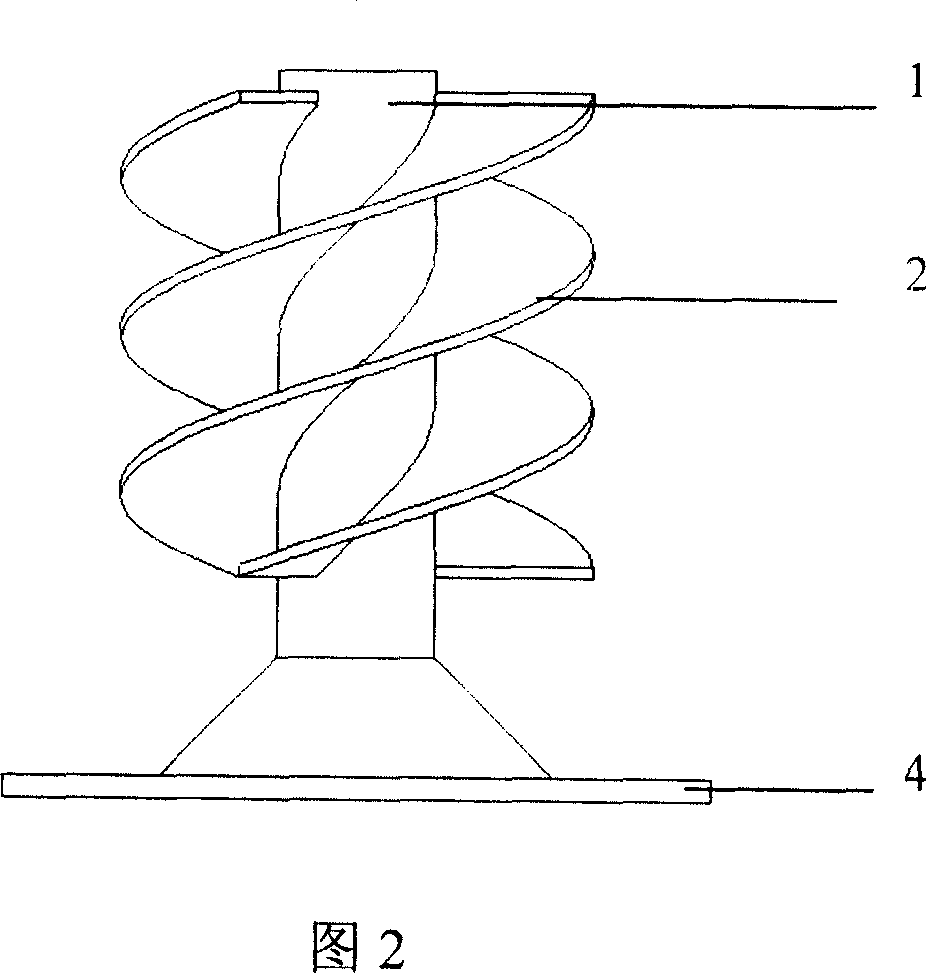

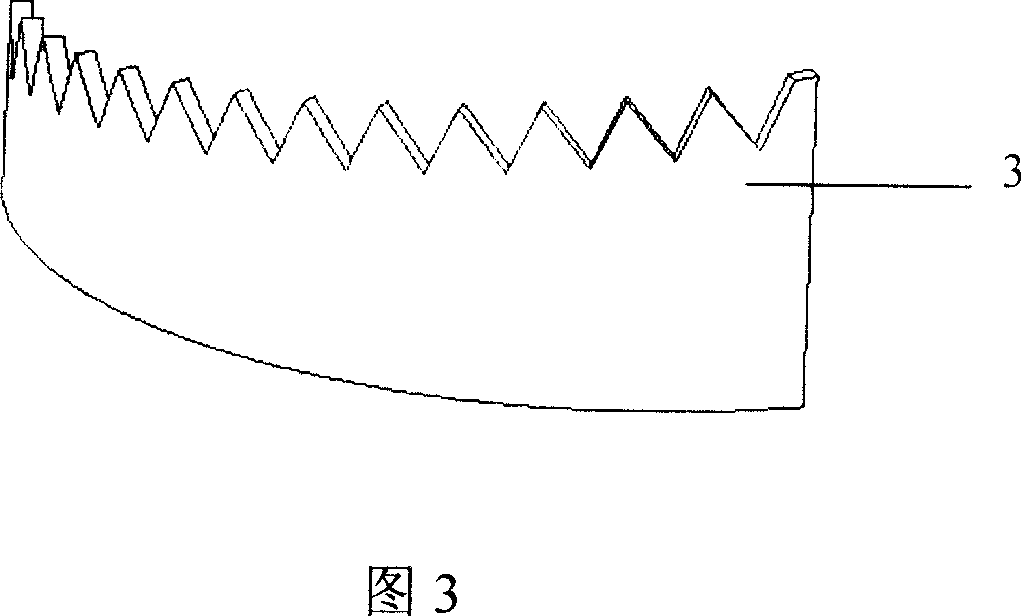

[0013] A helical rotor of a high-concentration hydraulic pulper includes a rotating core 1, a helical blade 2, a toothed blade 3 and a chassis 4. The upper part of the rotor core 1 is a cylinder, and the lower part is a cone. The cylinder part is welded with three single-line spiral blades. The spiral blades are positive helicoids and are evenly distributed on the rotor core; On the chassis and connected with the spiral blade, the fine teeth on the toothed blade are evenly distributed, which mainly shreds the waste paper, and also transports the slurry to the inner wall of the tank to form an overall vortex circulation of the slurry flow field ; The main function of the chassis is to connect with the transmission.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com