Method for producing golden convex points with more smooth surface

A technology of surface flattening and manufacturing method, applied in the field of gold bump manufacturing, can solve the problems of high edge portion of gold bumps, affecting the reliability of semiconductor devices, rough surface of gold bumps, etc., so as to improve the packaging density and improve the pass rate and welding ability, the effect of improving integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

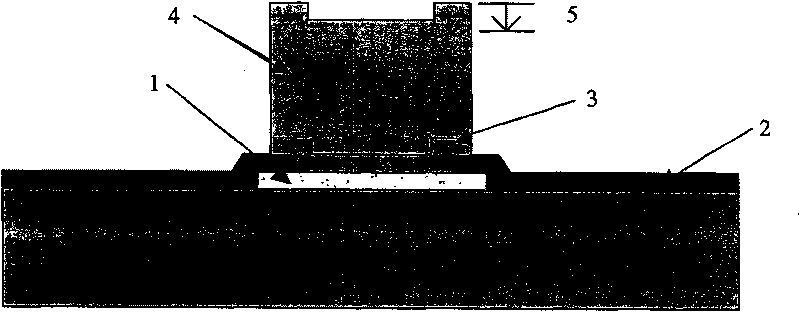

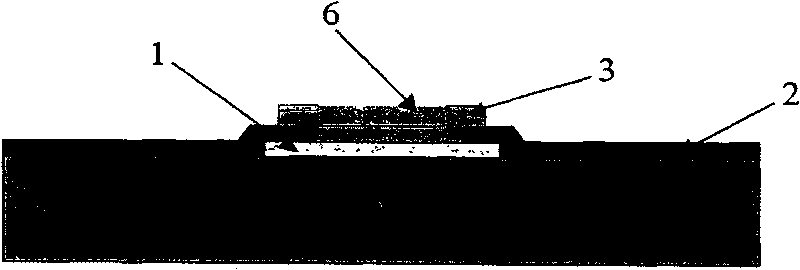

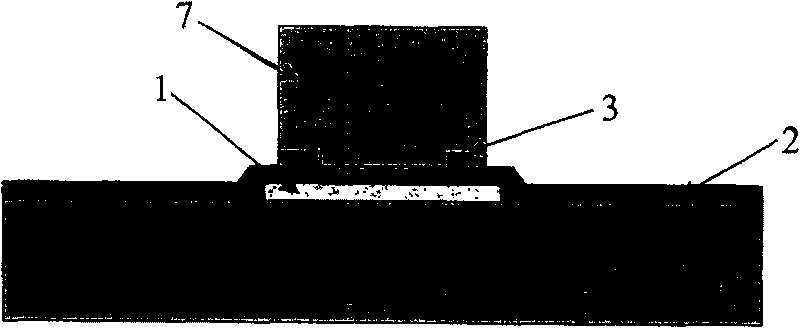

[0024] see below figure 2 and image 3 The gold bump manufacturing method according to the present invention will be described.

[0025] According to a technical solution of the present invention, the gold bump manufacturing method comprises the following steps:

[0026] Step 1, chemical vapor deposition (CVD) TiN passivation layer 2 is to be formed around the region of gold bump on the aluminum pad on the semiconductor wafer substrate, and the thickness of the TiN passivation layer 2 is 1-2 μm;

[0027] Step 2, sputtering and depositing the TiW-Au metal layer 3 under the gold bump, wherein the thickness of the TiW layer is 0.3-0.5 μm, and the thickness of the Au layer is 0.1-0.2 μm;

[0028] Step 3, electroplating on the TiW-Au metal layer 3 forms the first layer of electroplating gold (Au) layer 6, and the current density used for electroplating is 0.05-0.15 ampere / decimeter 2 ), the thickness of the formed electroplated gold layer 6 is slightly larger than the thickness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com