Stage device

一种载物台、基座的技术,应用在机电装置、测量装置、采用光学装置等方向,能够解决构造受制约、成本高、移动物体检测装置制约等问题,达到降低制造成本、减轻装置重量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

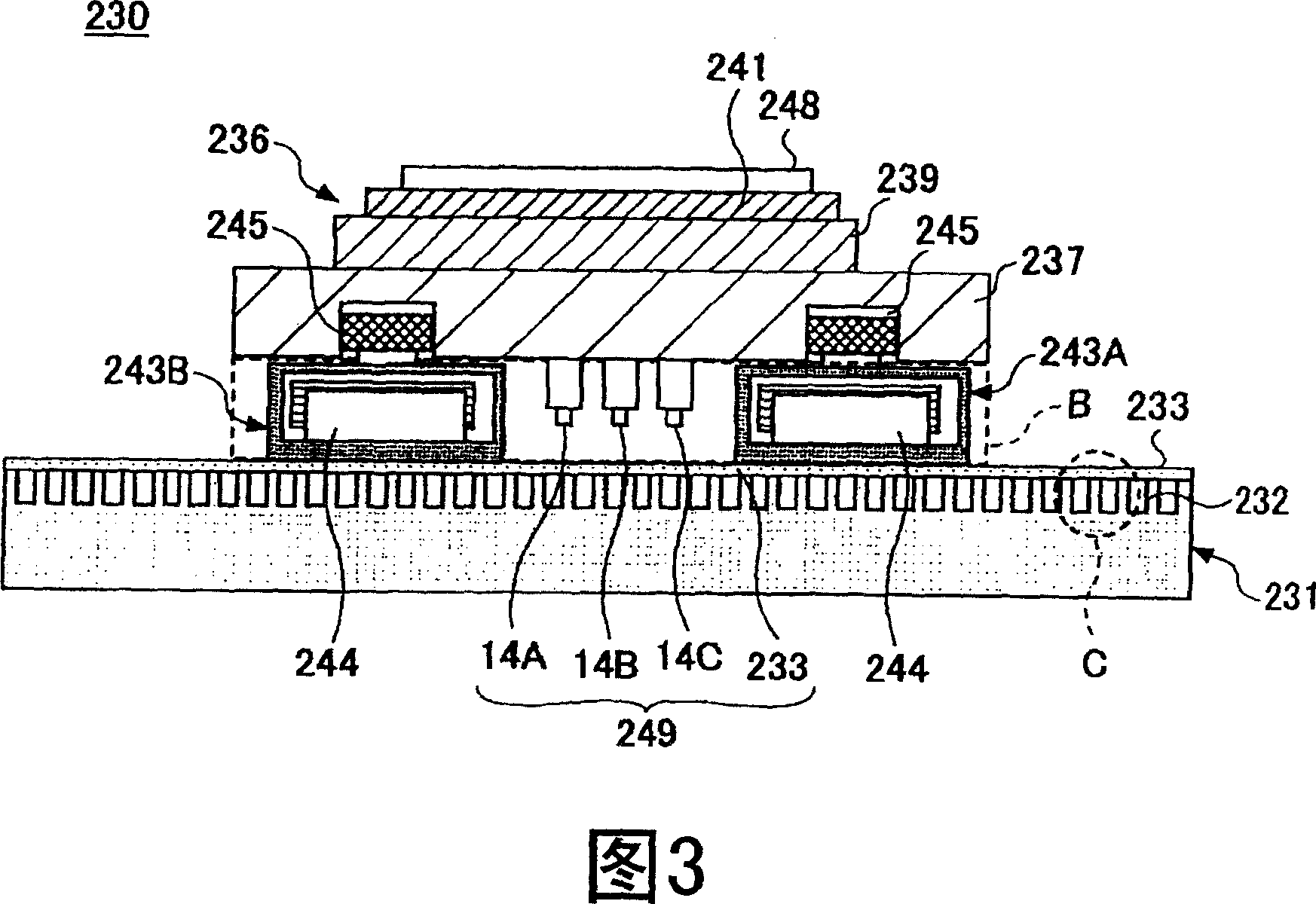

[0092] First, referring to FIG. 3 and FIG. 4 , the stage device 230 according to the first embodiment of the present invention will be described. 3 is a sectional view of the stage device of the first embodiment, and FIG. 4 is a plan view of the stage device corresponding to the area A shown in FIG. 3 .

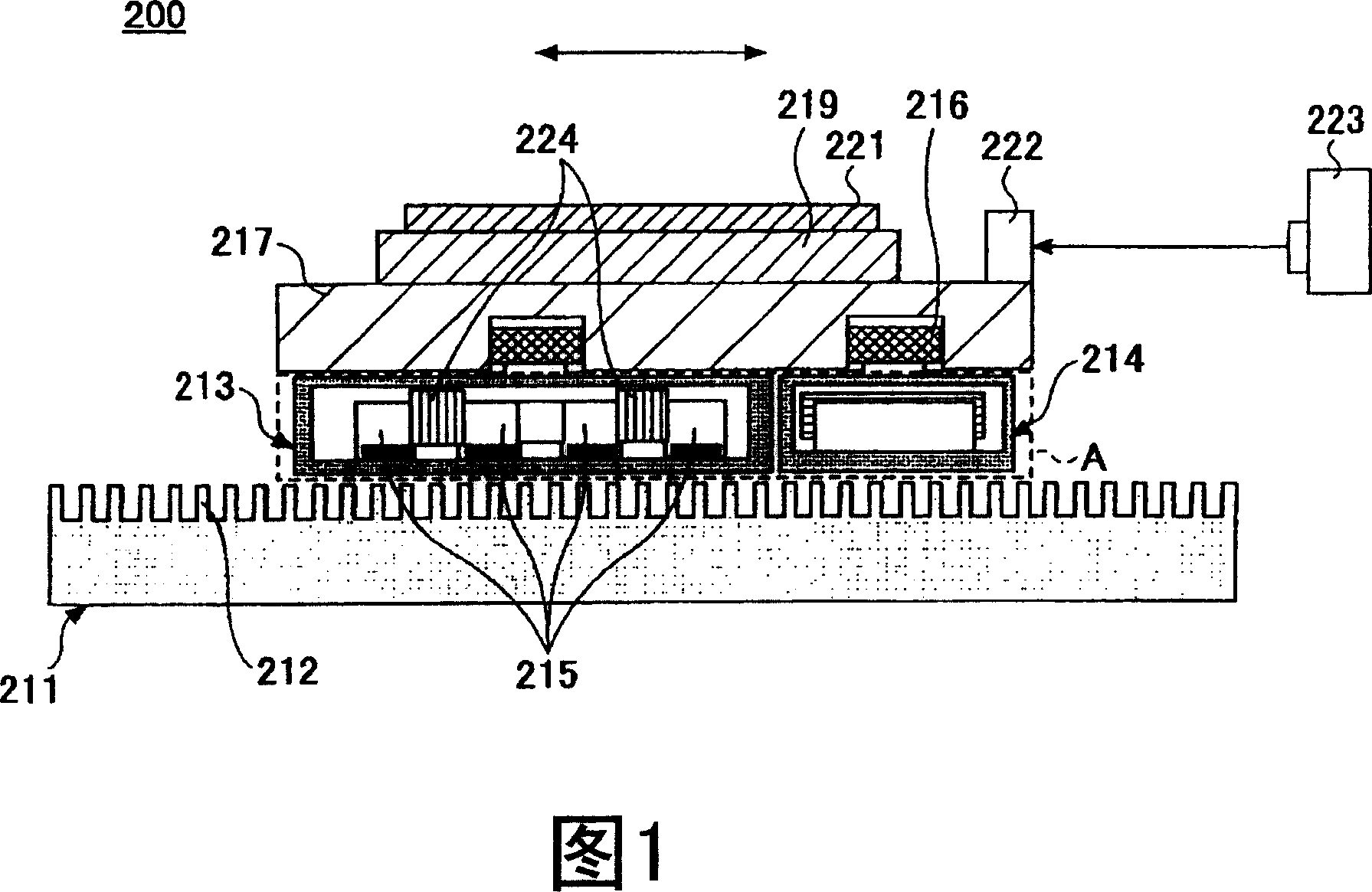

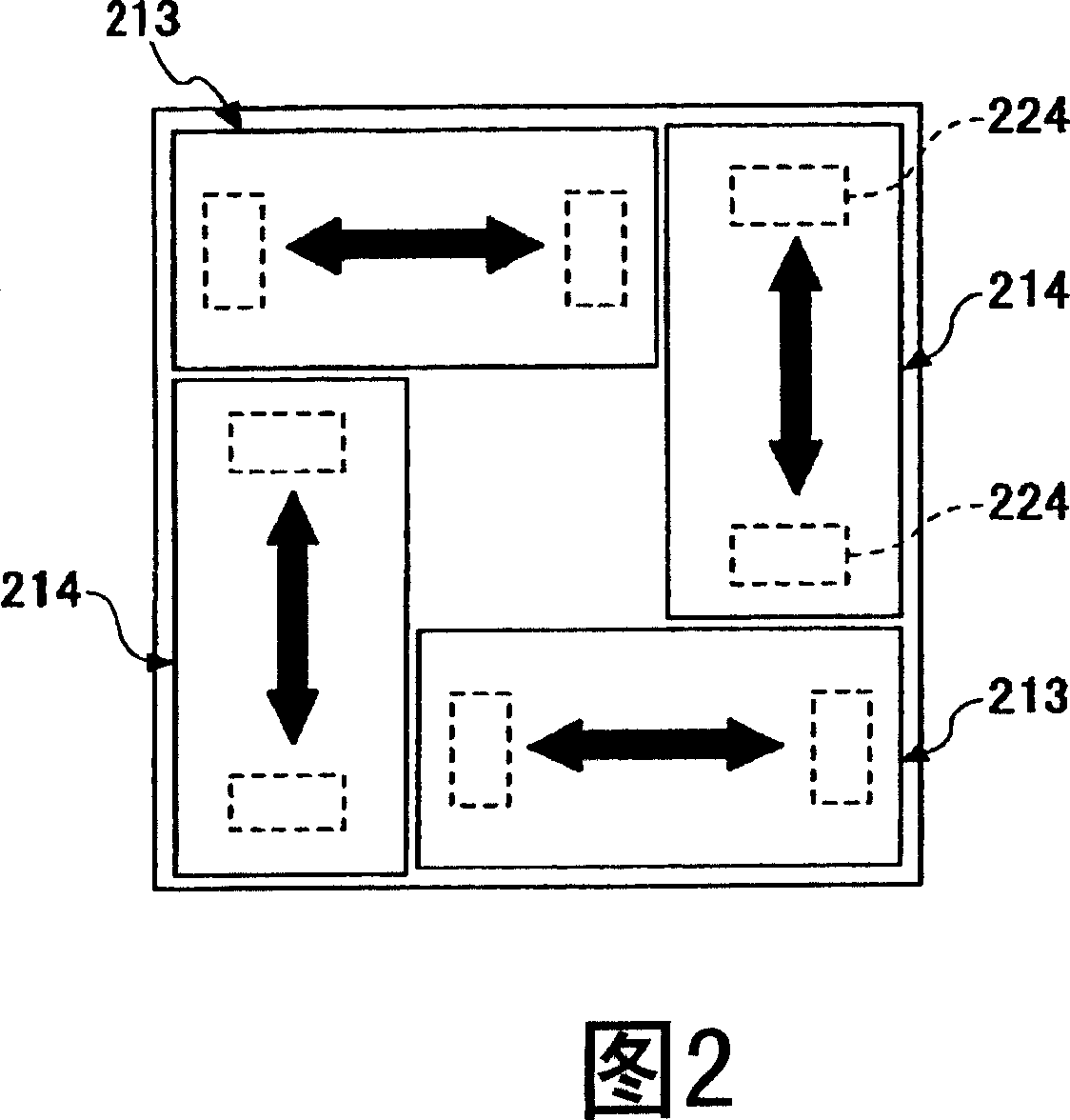

[0093] The stage device 230 is a device having a SAWYER motor drive unit. Referring to FIG. 3 , the stage device 230 is composed of a base 231 , a stage 236 , and a surface encoder 249 . A plurality of protrusions 232 are formed at a predetermined pitch on the surface of the base 231 . This predetermined pitch becomes the minimum unit when movable stage 237 moves. In addition, the base 231 is made of metal such as iron. Stage 236 is composed of movable stage portion 237 , fixed stage portion 239 , jig 241 , X-direction actuators 242A, 242B, Y-direction actuators 243A, 243B, and tilt drive portion 245 .

[0094] The movable stage portion 237 is a base portion driven by X-d...

no. 2 Embodiment

[0129] Referring to FIG. 10 and FIG. 11, a stage device 10 as a second embodiment of the present invention will be described. FIG. 10 is an exploded perspective view of a stage device 10 according to a second embodiment of the present invention, and FIG. 11 is a perspective view of a partially cutaway assembled state of the stage device 10 . The stage device 10 is used for moving a wafer to be moved to a predetermined position in, for example, a stepper for semiconductor manufacturing.

[0130] The stage device 10 is composed of a base 11, a stage 12, a surface encoder 24, a driving device, and the like. The base 11 is a base of the stage device 10, and is provided with linear motor structure parts 20A and 25A, a Z-direction electromagnet 30, two-dimensional angle sensors 14A to 14C, etc. which will be described later. In addition, in this embodiment, the case of using the two-dimensional angle sensors 14A to 14C employed in the first embodiment will be described as an exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com