Method for preparing carbon nano tube

A technology of carbon nanotubes and substrates, which is applied in the field of preparation of open carbon nanotubes, can solve the problems of carbon nanotube structure damage and the inability to ensure uniform length of carbon nanotubes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the preparation method of the present invention will be further described in detail below in conjunction with the accompanying drawings.

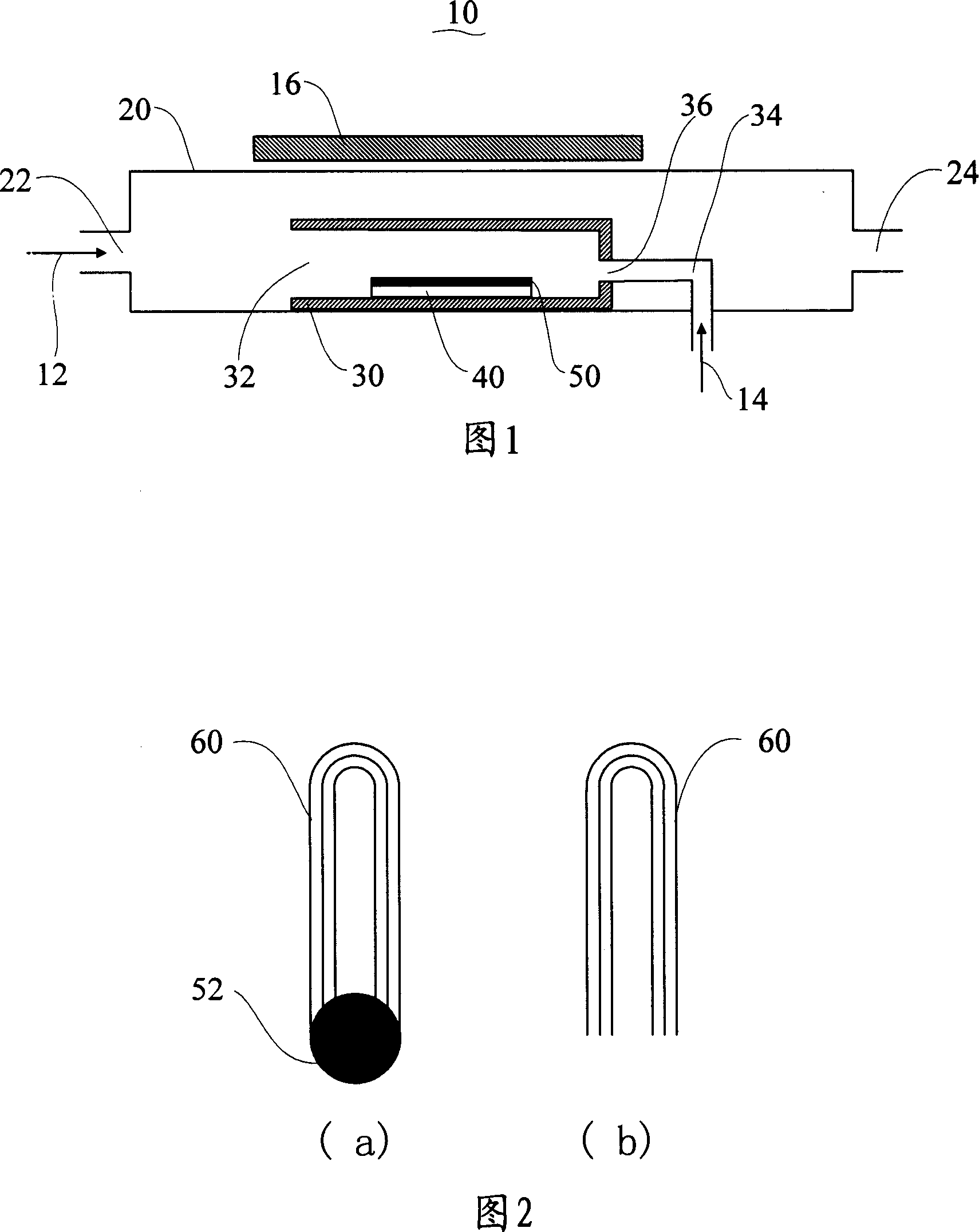

[0019] Please refer to Fig. 1, a kind of carbon nanotube preparation device 10 used in the carbon nanotube preparation method that the embodiment of the present invention provides, it comprises: a heating device 16; A reaction furnace 20; A quartz boat 30, it is arranged on reaction In the furnace 20; a gas guiding device, one end of which is connected to the quartz boat 30; a substrate 40, which is arranged in the quartz boat 30, and a catalyst layer 50 is formed on the surface of the substrate 40.

[0020] The reaction furnace 20 includes an air inlet 22 and a gas outlet 24 opposite thereto, wherein the air inlet 22 is used to feed the reaction gas 12, for example, the carbon nanotube growth stage and the growth stage can pass through the gas outlet respectively. The gas port 22 feeds the carrier gas and the carb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com