High-refractivity reflecting microbead glass

A technology of reflective microbeads and high refractive index, applied in the field of high refractive index reflective microbead glass, can solve the problems of low reflectivity of microbeads, and achieve the effects of simple production process, prolonging service life and reducing high temperature viscosity

Inactive Publication Date: 2007-03-28

SICHUAN HENGHUI NEW TECH DEV

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The above information introduces the research and production of reflective glass microsphere materials, but the reflectivity of the microspheres is relatively low, at 550Cd / m 2 the following

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

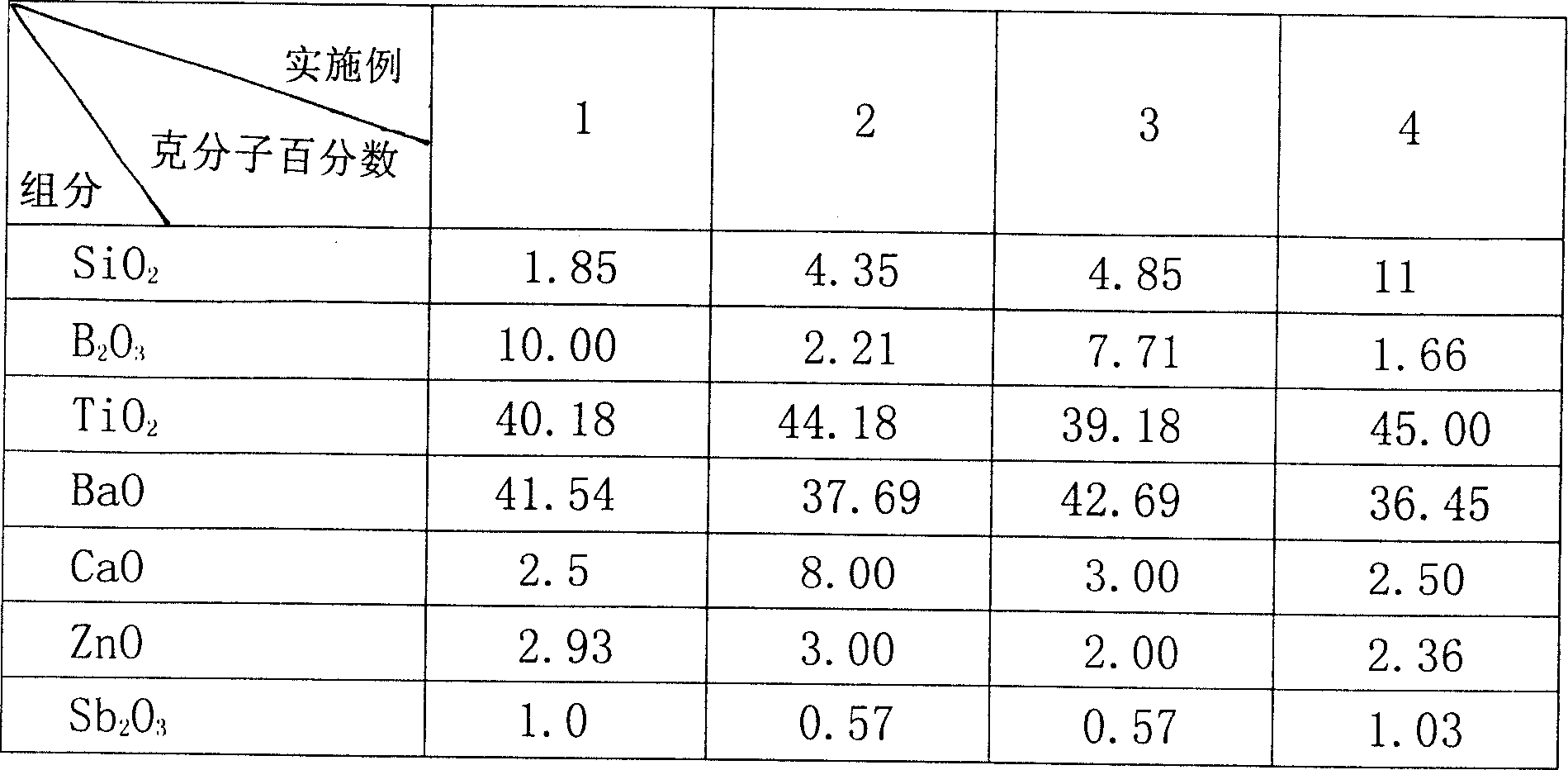

[0031] Examples of microbead glass of the present invention are shown in Table 1.

[0032] Table 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides a high-refractivity, light-reflecting microspheric glass, comprising the following components in gram molecular percent: SiO2 1-12, B2O3 1.5-11, TiO2 20-55, BaO2 5-56, CaO 2-10, ZnO 0.3-10 and Sb2O3 0.1-2. And it has characters of high reflection brightness, no harmful components, and safety and no pollution.

Description

Technical field: [0001] The present invention relates to reflective beaded glass, especially high refractive index reflective beaded glass. Background technique: [0002] A lot of work has been done on the microbead glass material by predecessors. "Glass and Enamel" in 1988, 16(6)-36 "Glass Microbeads and Application Research" introduced that the main composition of glass is SiO 2 B 2 o 3 、Al 2 O, BaO, TiO 2 , The refractive index is 1.87~2.04 or 2.10~2.21, respectively, the magazine 2001, 29 (5)-44-47 article from the aspects of the influence factors of the performance parameters of the glass beads, the selection of the chemical composition system and so on. Changchun Institute of Optics and Fine Mechanics Journal 1996, 19(4)-4-49 "Research and Production of High Refractive Index Glass Beads" describes the powder method of forming beads. China Science and Technology Achievement Library 194201782 "Research and Production of High Refractive Index Glass Beads" describes ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C03C12/00C03C3/066

CPCC03C3/066C03C12/02

Inventor 熊喜定

Owner SICHUAN HENGHUI NEW TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com