Steel-continuous-fiber composite-rib reinforced concrete earthquake-resisting structure

A technology for strengthening concrete and concrete structures, which can be used in building structures, buildings, etc., and can solve problems such as limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

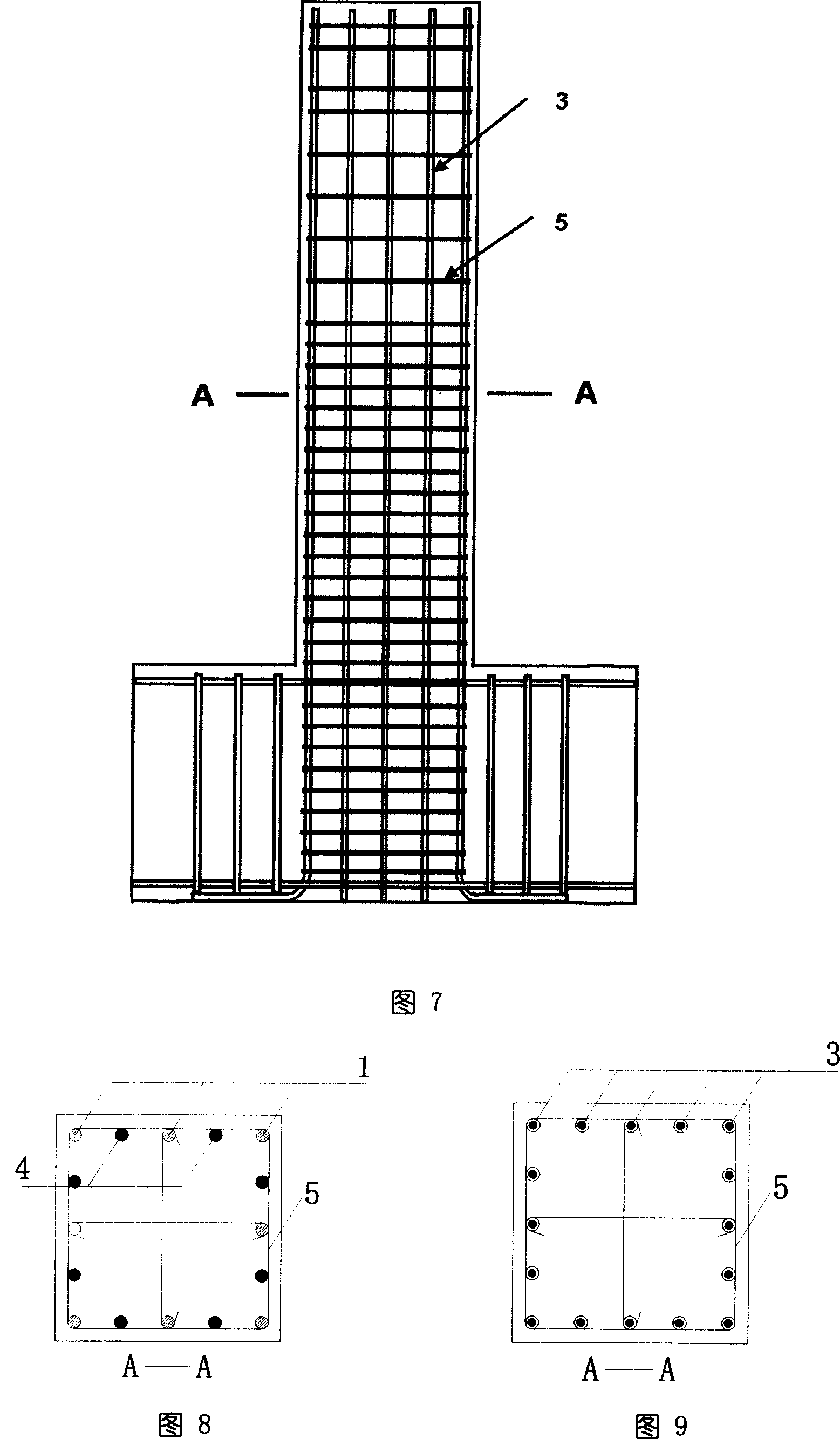

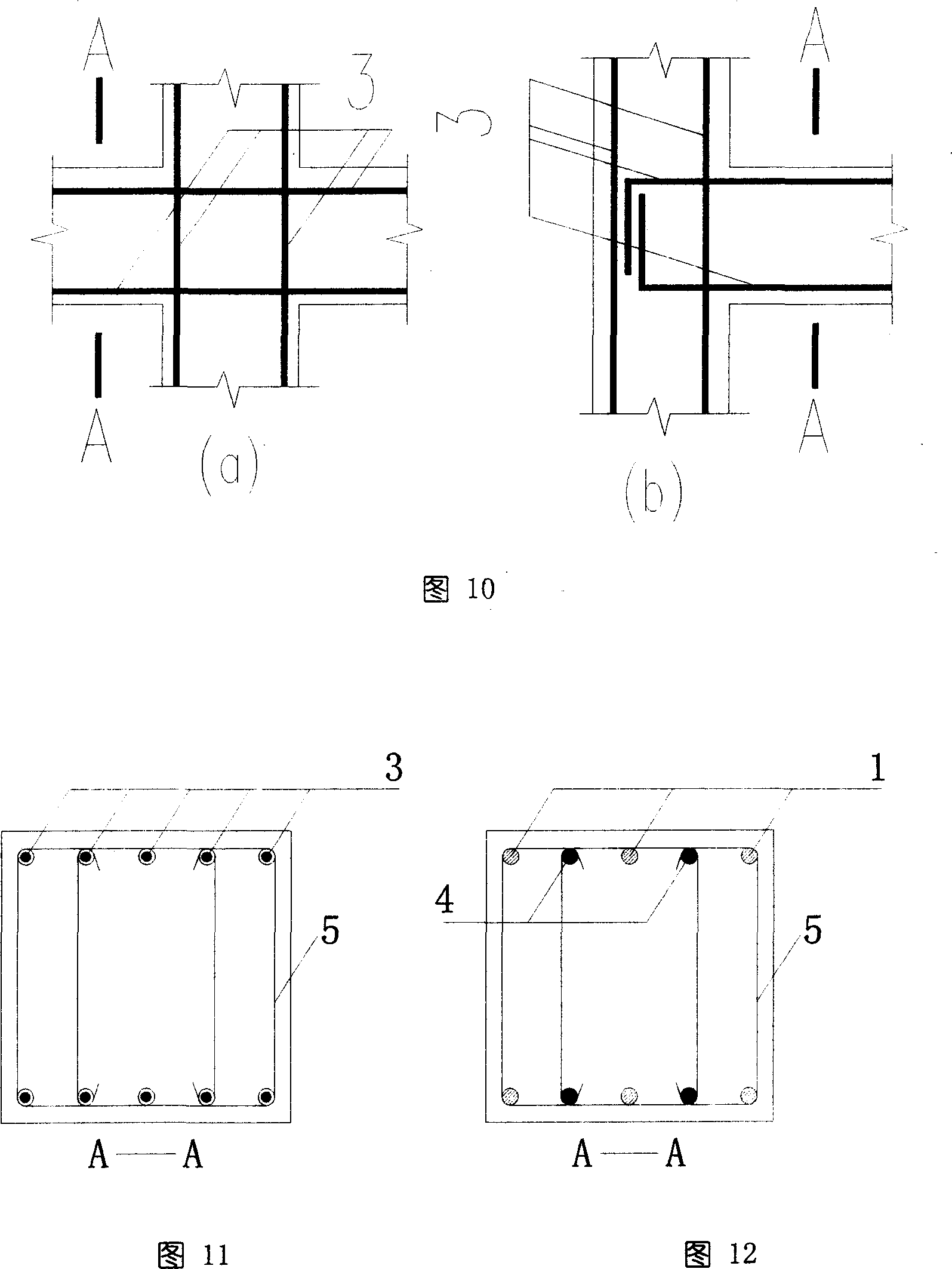

[0070] (1) Basic principles of design

[0071] For the purpose of obtaining stable secondary rigidity and achieving moderate earthquake repairability, the SFCB composite bar obtained by compounding FRP and steel bar is used to strengthen the concrete anti-seismic structure, and the anti-seismic performance is improved by controlling its bonding performance with concrete .

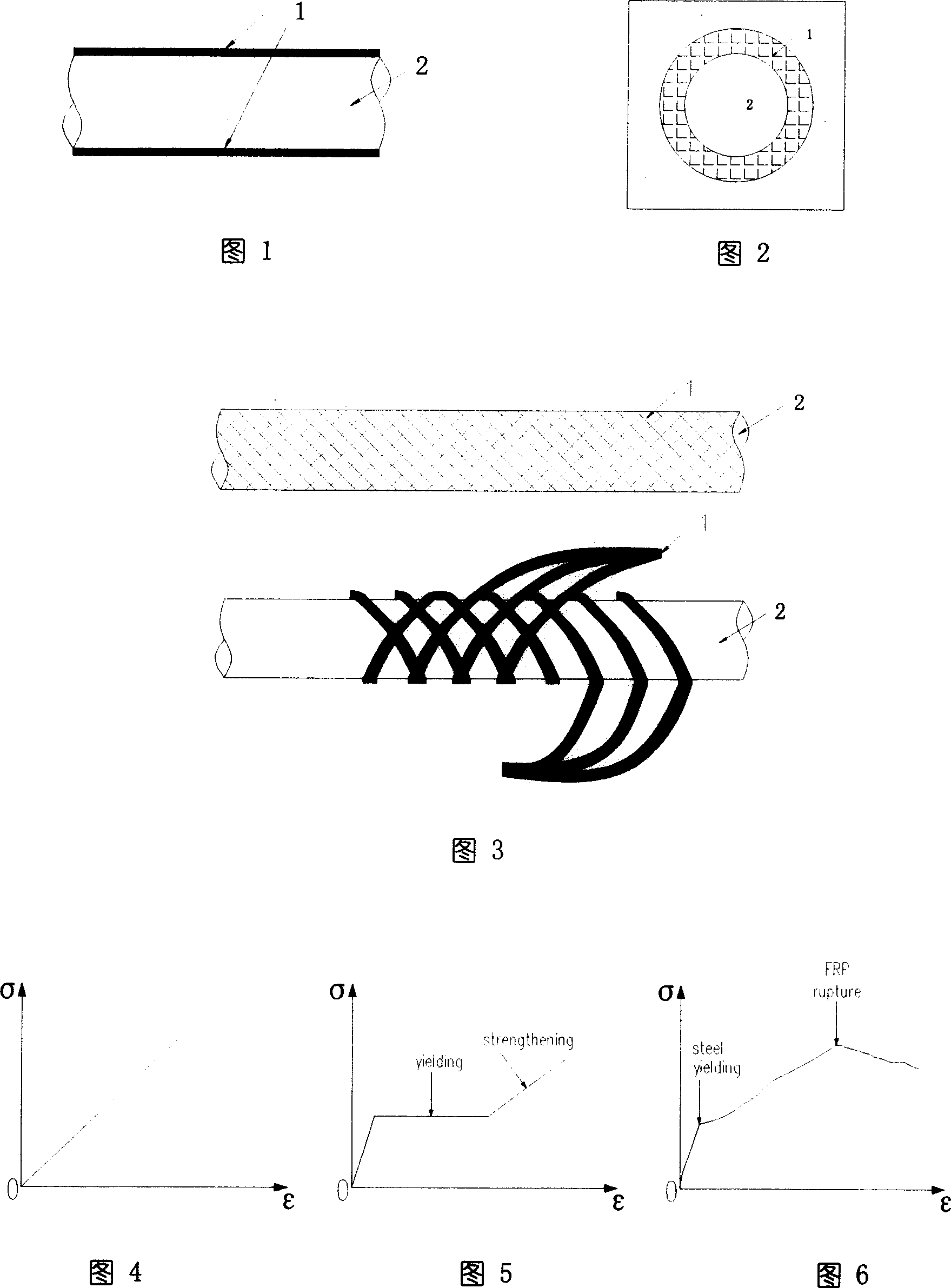

[0072] When manufacturing SFCB, based on structural performance requirements, using classical lamination theory and hybrid theory, changing various parameters (fiber type, resin type, steel bar type, steel, fiber ratio, surface treatment, fiber winding angle and method, etc.) Properties of steel-continuous fiber composite bars (SFCB), systematically studied to summarize its basic mechanical properties.

[0073] At the same time, through some effective methods to control the bond performance between SFCB and concrete, as well as SFCB-concrete bond mechanism and load-slip curve, the corresponding structure i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com