Sterilizer

A sterilizing device and drying device technology, which is applied in food preservation, dryers, lighting and heating equipment, etc., can solve the problems of few practical examples, small effect, weak bactericidal power, etc., and achieve the effect of strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

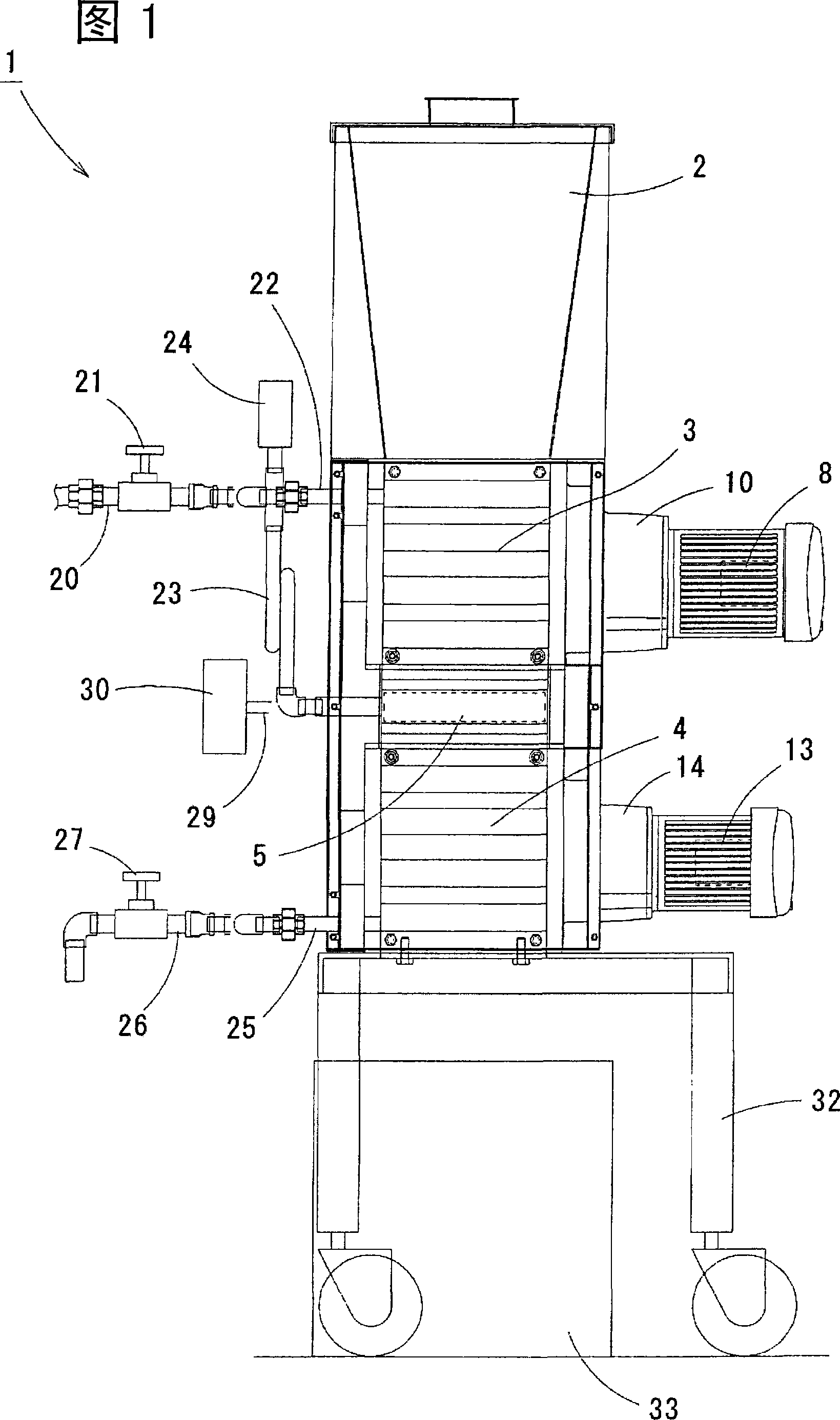

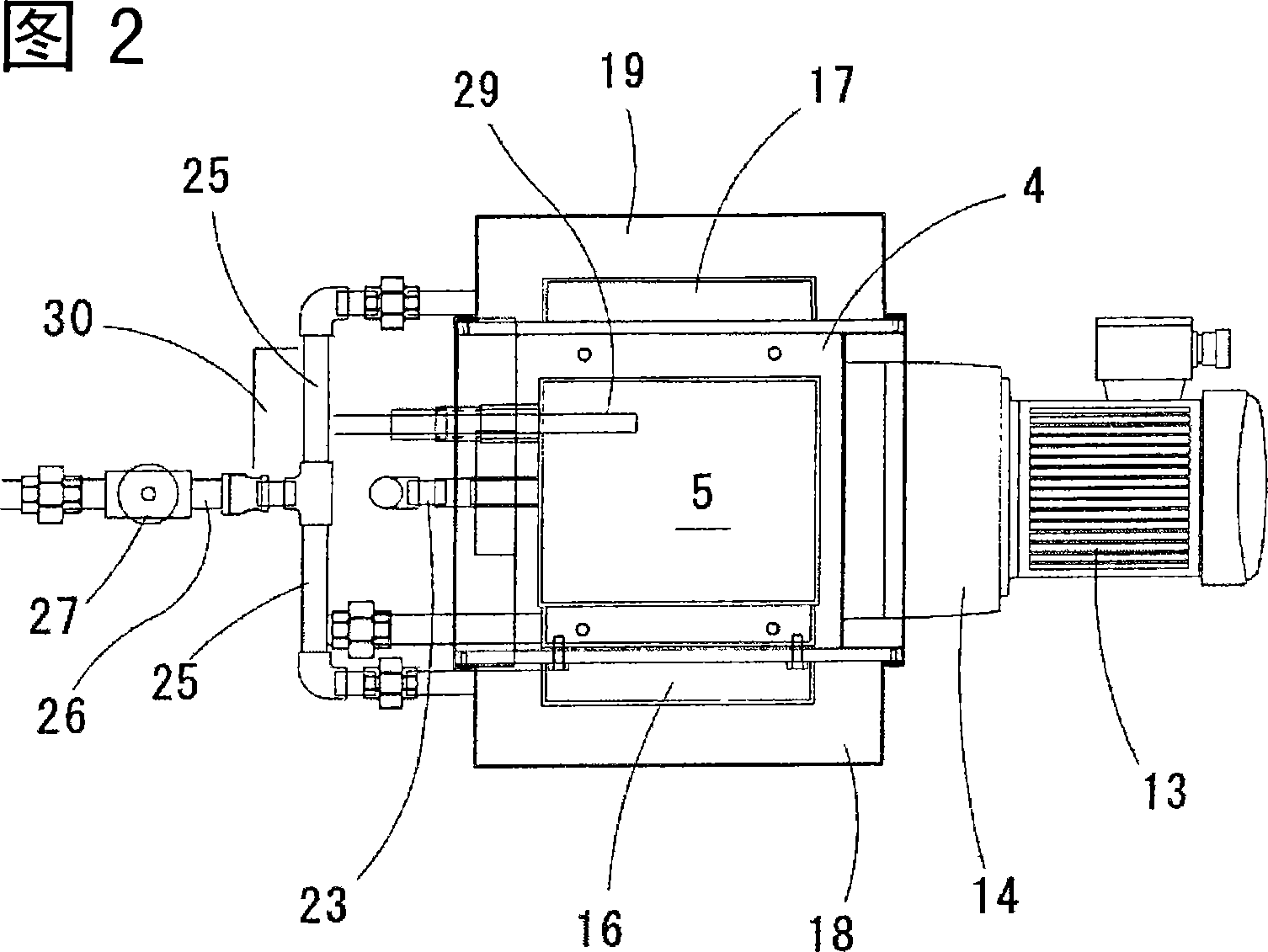

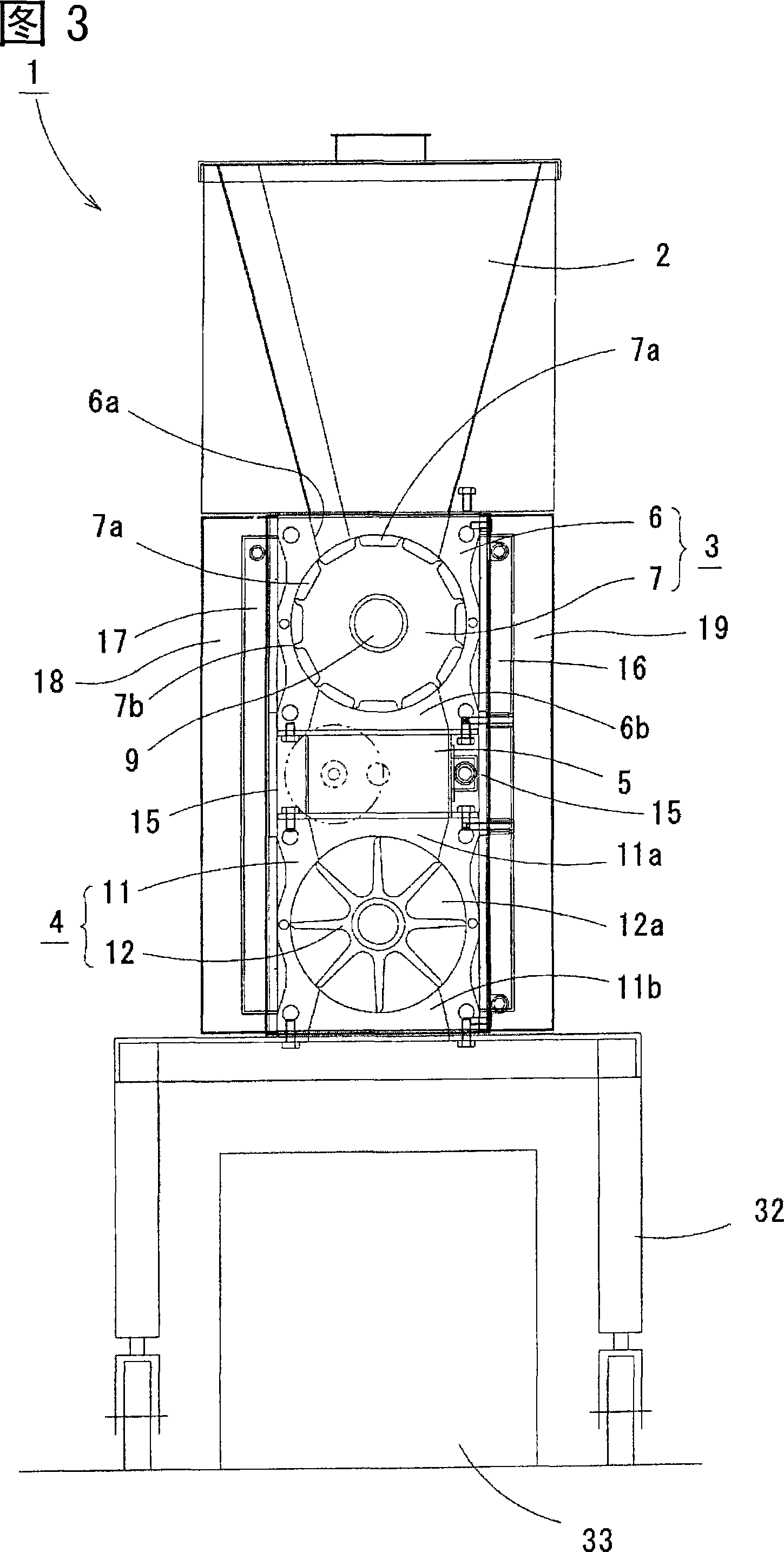

[0047] The best mode for implementing the present invention will be described in detail below with reference to the drawings. First, the sterilization device of the first embodiment will be described.

[0048]As shown in FIG. 1, the sterilization device 1 includes a hopper into which powder or granular materials are placed, a first rotary valve 3 provided below the hopper 2, a second rotary valve 4 provided below the rotary valve 3, and The airtight space 5 formed between the first rotary valve 3 and the second rotary valve 4 described above. As shown in Fig. 1, the planar shape of the hopper 2 is formed into a square shape, and is formed by gradually narrowing from top to bottom. In addition, as shown in FIG. 3, the first rotary valve 3 includes a housing 6, a valve body 7 housed in the housing 6, and a first drive motor 8 that drives the valve body 7 to rotate. The housing 6 is formed with a housing space (notation omitted) in which the valve main body 7 is housed and can be rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com