Medical leading wire and manufacture thereof

A technology of guiding wires and core wires, applied in the direction of guiding wires, catheters, etc., to reduce the burden and reduce the effect of invasion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] In the following detailed description of the embodiments, the same reference numerals are used for the same kind of structural features.

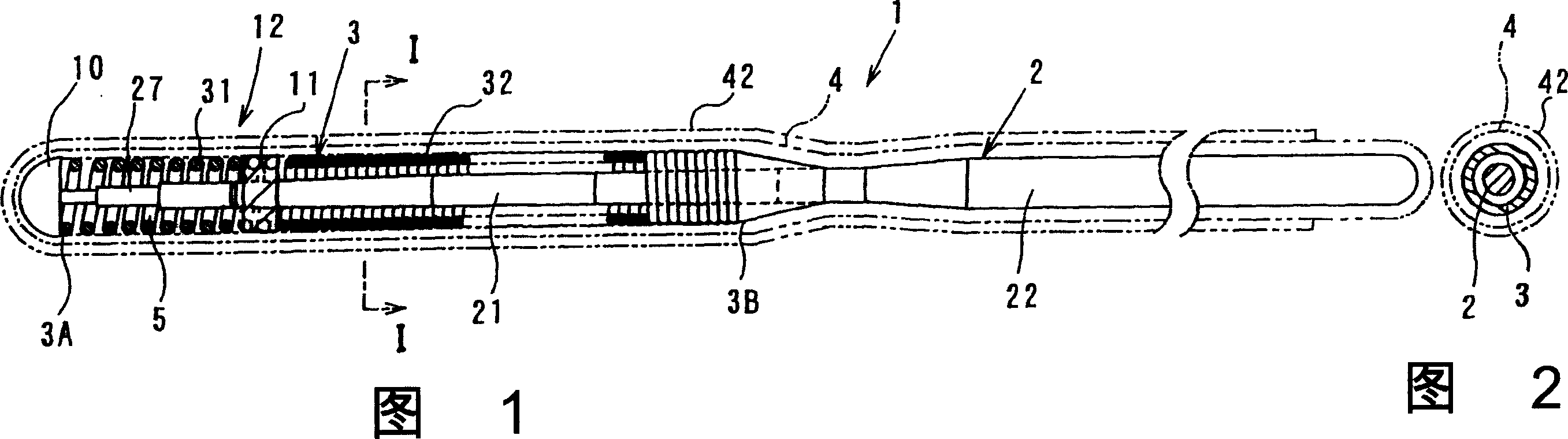

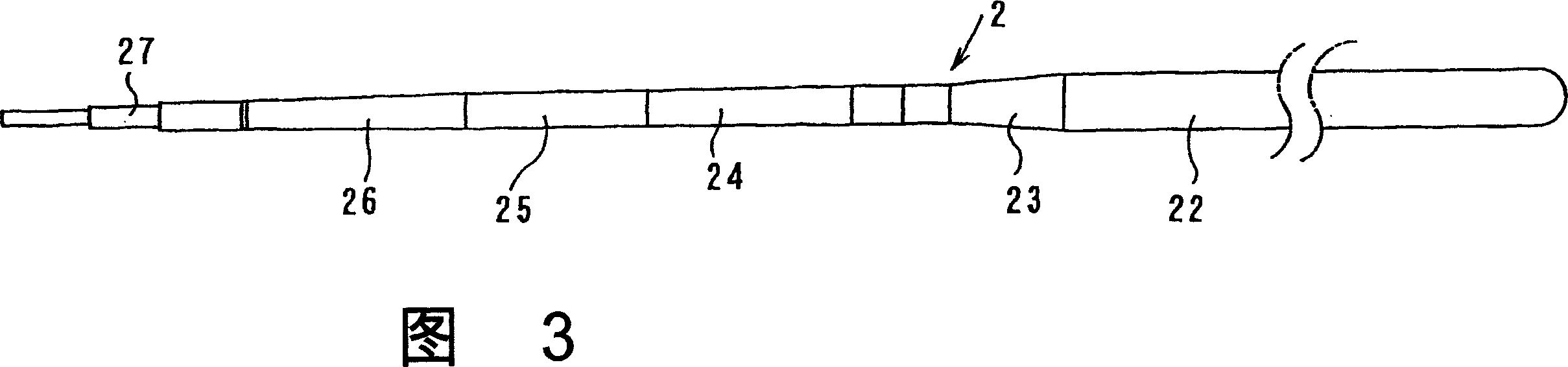

[0064] Referring to FIGS. 1 to 4, there is shown a medical guide wire 1 according to a first embodiment of the present invention. The medical guide wire 1 (hereinafter simply referred to as "guide wire 1") has an elongated core wire 2 and is sheathed in a thin A helical spring 3 on the outer surface of the distal portion 21 of the long core wire 2 . The elongated core wire 2 is made of stainless steel wire and its distal portion 21 is about 300 mm in length, while the remaining guide wire 1 acts as a proximal portion 22 extending in length by about 1200 mm or about 2700 mm.

[0065] The distal portion 21 has a large tapered portion 23 of a taper, a small tapered portion 24 of a taper, a cylindrical portion 25, a small tapered portion 26 of a taper and a multi-step flat portion 27 (for example, from the far The thickness from the end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com