Hydrogen permeation alloy and a method of manufacturing the same

An alloy and hydrogen permeable technology, applied in separation methods, chemical instruments and methods, methods for reacting gas media with gas media, etc., can solve problems such as lack of hydrogen permeability, and achieve shortened length and excellent hydrogen permeability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

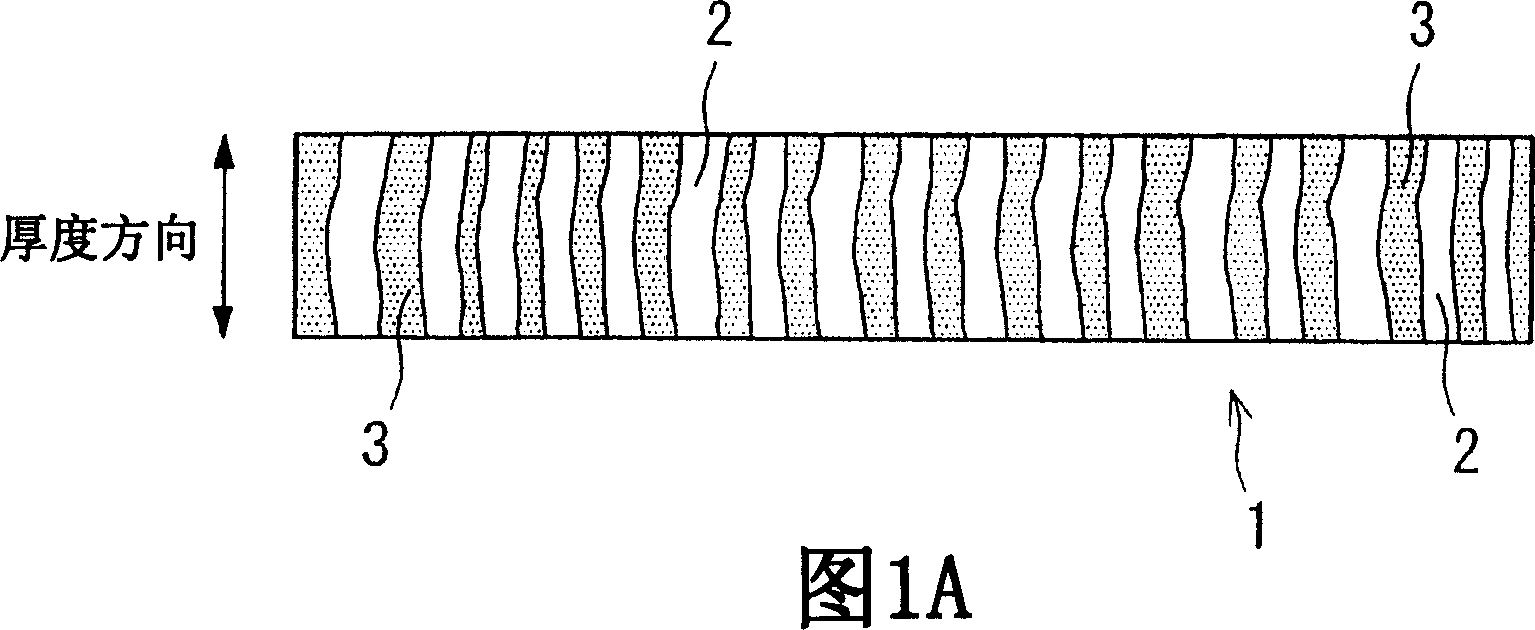

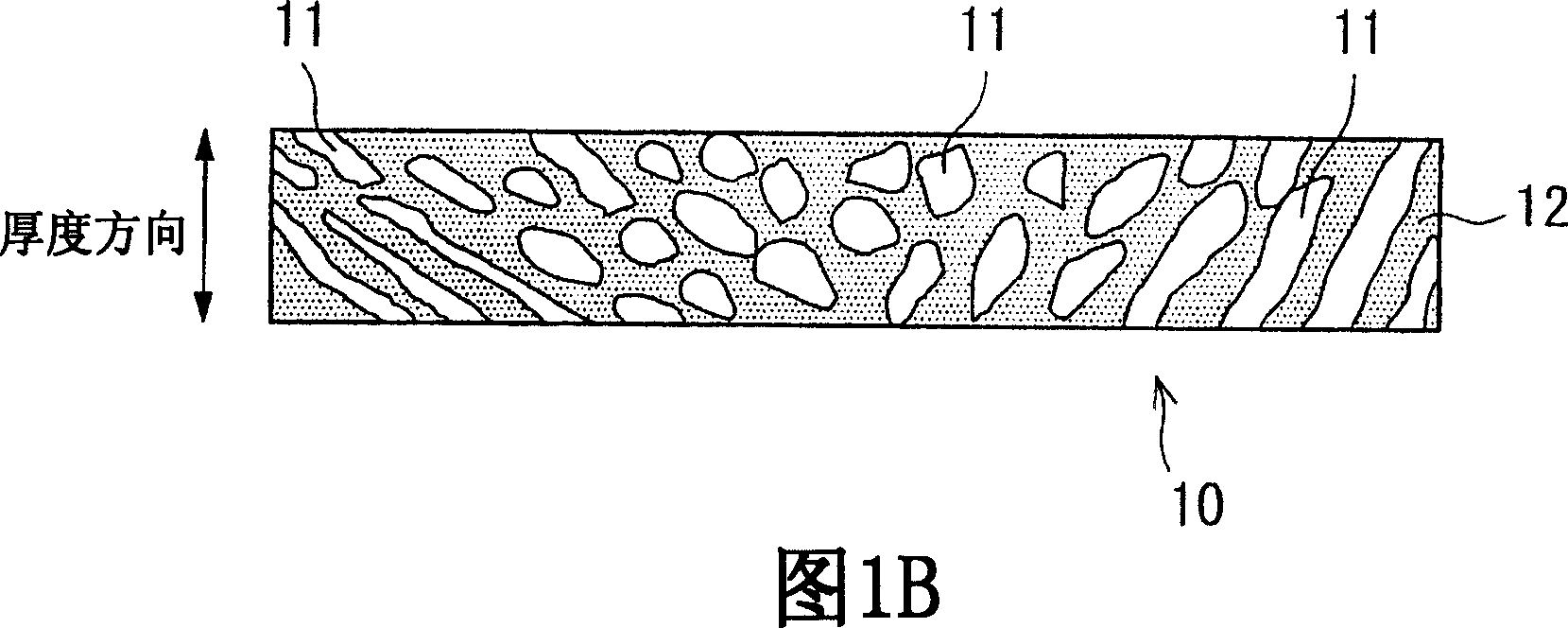

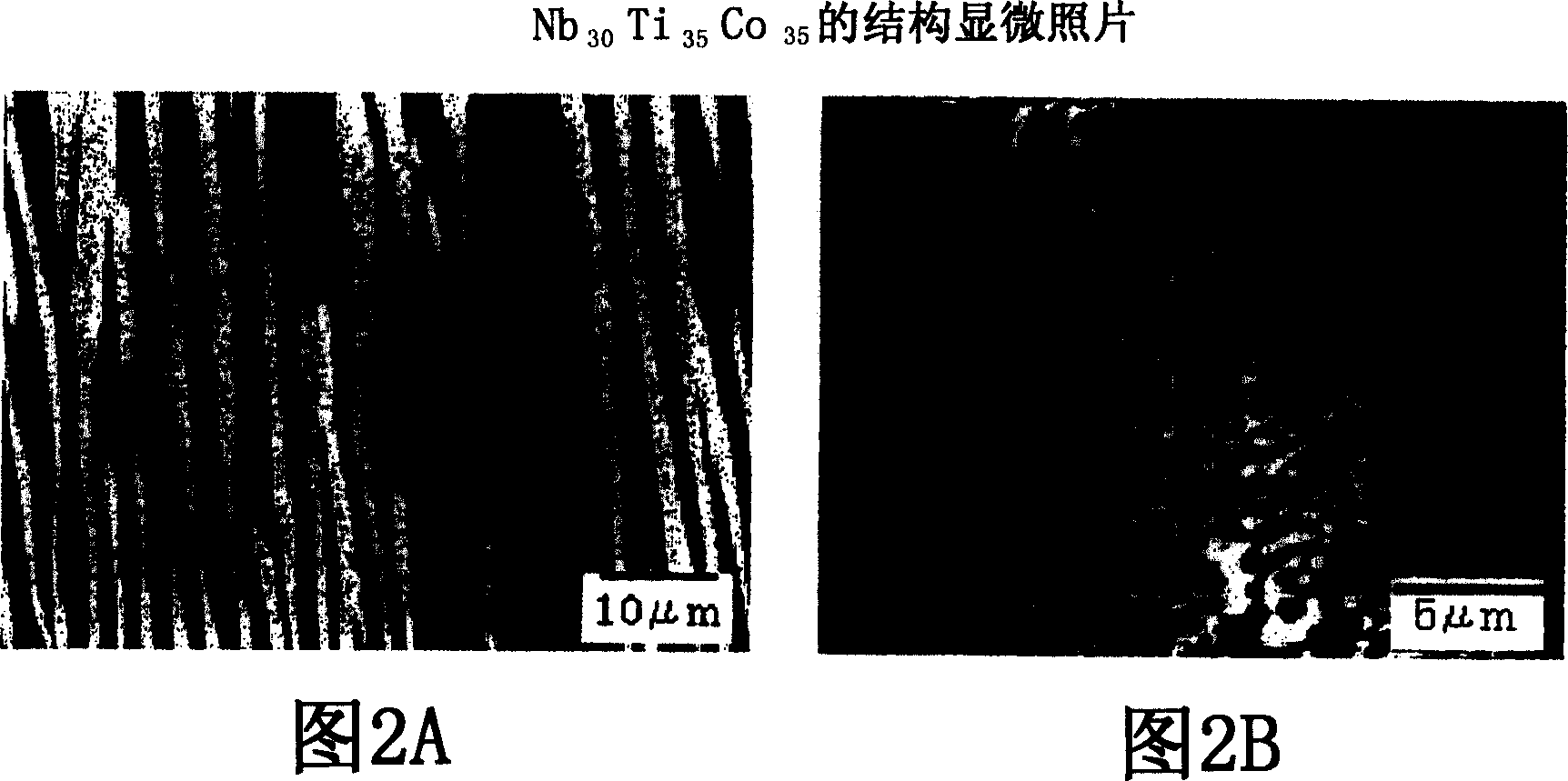

[0027] The hydrogen permeable alloy of the present invention is a multiphase hydrogen permeable alloy including a phase responsible for hydrogen permeability and a phase responsible for resistance to hydrogen embrittlement. The types of these phases are not particularly limited, but are generally Nb-Ti-Co-based alloys in which the phase responsible for hydrogen permeability is the (Nb,Ti) phase and the phase responsible for hydrogen embrittlement resistance is the CoTi phase. Regarding the quantitative ratio of the Nb-Ti-Co alloy, the present invention is not particularly limited, and as a representative example, it can be proposed to use the general formula Nb x Ti (100-x-y) co y (here x≤70, 20≤y≤50, x+y<100 (mol%)) represents the alloy.

[0028] The relationship between the above quantitative ratios and physical properties will be briefly described below. First, when the Nb content exceeds the range defined above, hydrogen embrittlement tends to occur. Therefore, the Nb ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com