Hydrogen permeation alloy material and preparation thereof

An alloy material and a hydrogen permeation technology are applied in the field of hydrogen permeable alloy materials and their preparation, which can solve problems such as incapability and achieve the effect of excellent hydrogen permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

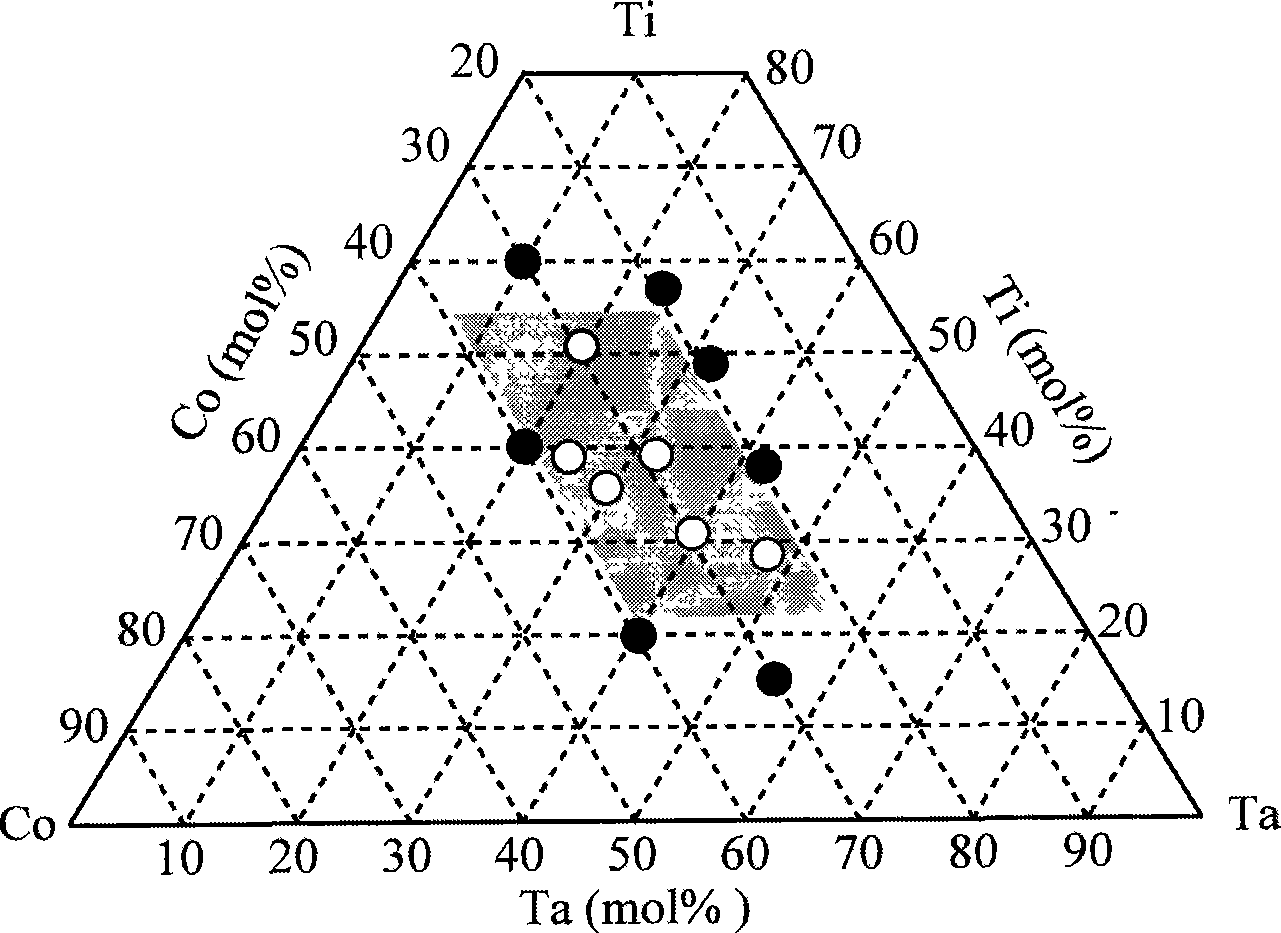

[0022] Example 1: Preparation of Ti 26.9 Co 25.0 Ta 47.8 Alloy (mole percentage composition is 26.9mol% Ti, 25.0mol% Co, 47.8mol% Ta) material

[0023] The preparation method is as follows:

[0024] 1) Weigh out 0.054 mol of titanium (Ti) with a purity of 99%, 0.050 mol of cobalt (Co) with a purity of 99.5%, and 0.096 mol of tantalum (Ta) with a purity of 99.5%. The total mass of the metal raw materials is about 22.902 grams.

[0025] 2) Put the weighed tantalum, titanium, and cobalt raw materials into a non-consumable vacuum arc furnace and vacuumize to 3×10 -3 Below Pa, fill with high purity argon to 4×10 4 Pa, smelted into Ti 27 Co 25 Ta 48 alloy.

[0026] The alloy material includes 26.9mol% of titanium, 25.0mol% of cobalt and 47.8mol% of tantalum by mole percentage. The total content of titanium, cobalt and tantalum is 99.7mol%. Impurities include niobium (Nb) and nickel (Ni). , Silver (Ag). The alloy is composed of a BCC-(Ta, Ti) solid solution with a body-centered cubic con...

Embodiment 2

[0026] The alloy material includes 26.9mol% of titanium, 25.0mol% of cobalt and 47.8mol% of tantalum by mole percentage. The total content of titanium, cobalt and tantalum is 99.7mol%. Impurities include niobium (Nb) and nickel (Ni). , Silver (Ag). The alloy is composed of a BCC-(Ta, Ti) solid solution with a body-centered cubic configuration and a B2-TiCo metal compound, and is composed of a primary phase (Ta, Ti) and a eutectic phase {TiCo+(Ta, Ti)}. After palladium plating by magnetron sputtering, Ti is measured with a hydrogen permeability tester 27 Co 25 Ta 48 The hydrogen permeability of the alloy at 673K is 2.8×10 -8 (mol H 2 m-1s -1 Pa -0.5 ), and has excellent resistance to hydrogen embrittlement. Example 2: Preparation of Ti 28.5 Co 26.9 Ta 43.6 Alloy (mole percentage composition is 28.5mol% Ti, 26.9mol% Co, 43.6mol% Ta) material

[0027] The preparation method is as follows:

[0028] 1) Weigh out 0.058 mol of titanium (Ti) with a purity of 99%, 0.054 mol of cobalt (Co...

Embodiment 3

[0031] Example 3: Preparation of Ti 28.9 Co 30.1 Ta 39.0 Alloy (mole percentage composition is 28.9mol% Ti, 30.1mol% Co, 39.0mol% Ta) material

[0032] The preparation method is as follows:

[0033] 1) Weigh out 0.075 mol of titanium (Ti) with a purity of 99%, 0.075 mol of cobalt (Co) with a purity of 99.5% and 0.100 mol of tantalum (Ta) with a purity of 99%. The total mass of the metal raw materials is about 26.105 grams.

[0034] 2) Put the weighed tantalum, titanium, and cobalt raw materials into a non-consumable vacuum arc furnace and vacuumize to 3×10 -3 Below Pa, fill with high purity argon to 4×10 4 Pa, smelted into Ti 30 Co 30 Ta 40 alloy.

[0035] The alloy material includes 28.9 mol% titanium, 30.1 mol% cobalt and 39.0 mol% tantalum by mole percentage. The total content of titanium, cobalt and tantalum is 98.0 mol%. Impurities include niobium (Nb) and nickel (Ni). , Copper (Cu), zinc (Zn), silver (Ag), silicon (Si). The alloy is composed of a BCC-(Ta, Ti) solid solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com