Eject nozzle and eject system

A technology of injection nozzles and gas supply channels, applied in injection devices, liquid injection devices, casting and molding equipment, etc., can solve the problems of large-scale injection units, lag in injection control, and quality reduction, and achieve miniaturization, resistance reduction, The effect of reducing manufacturing cost and construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

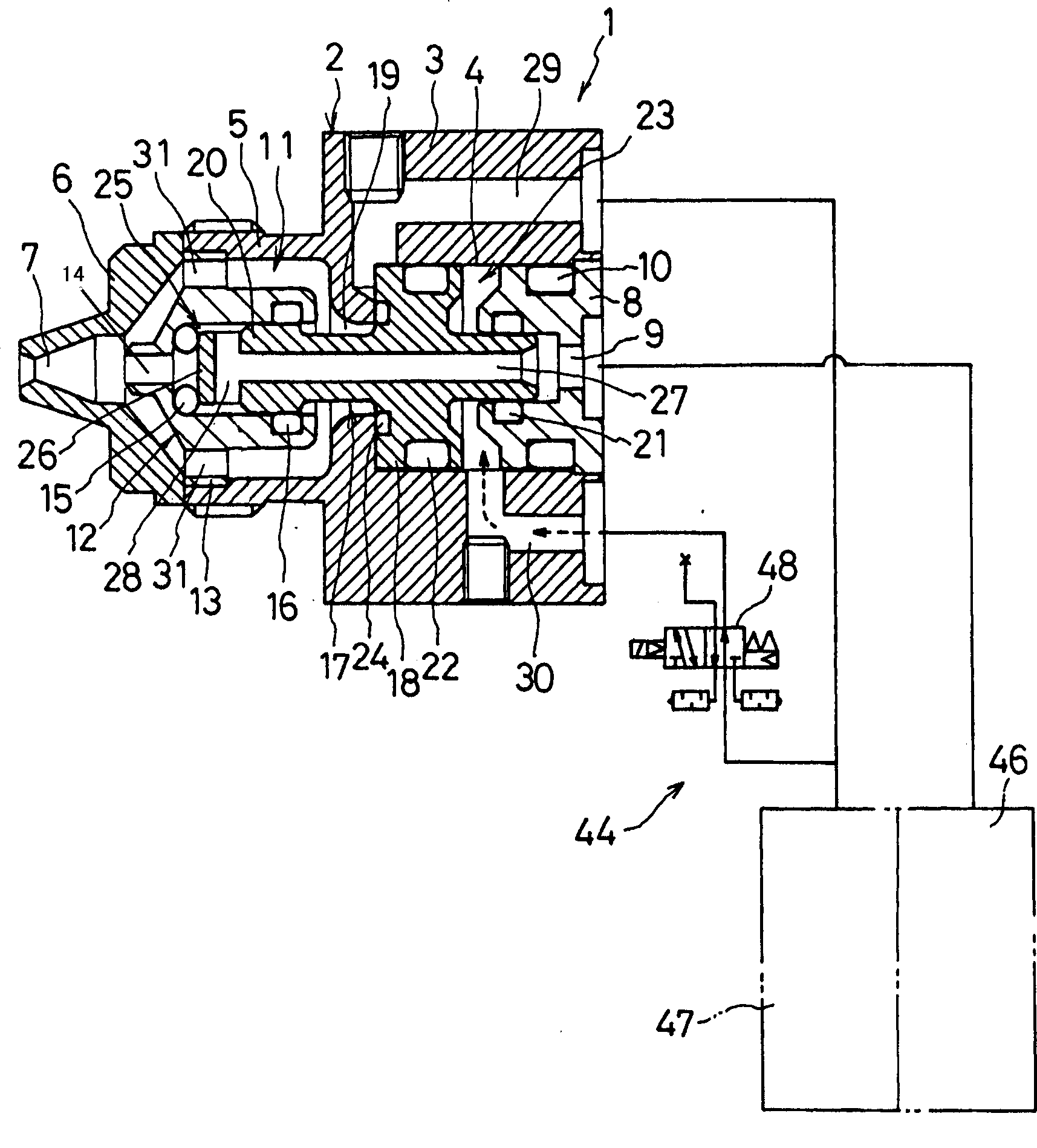

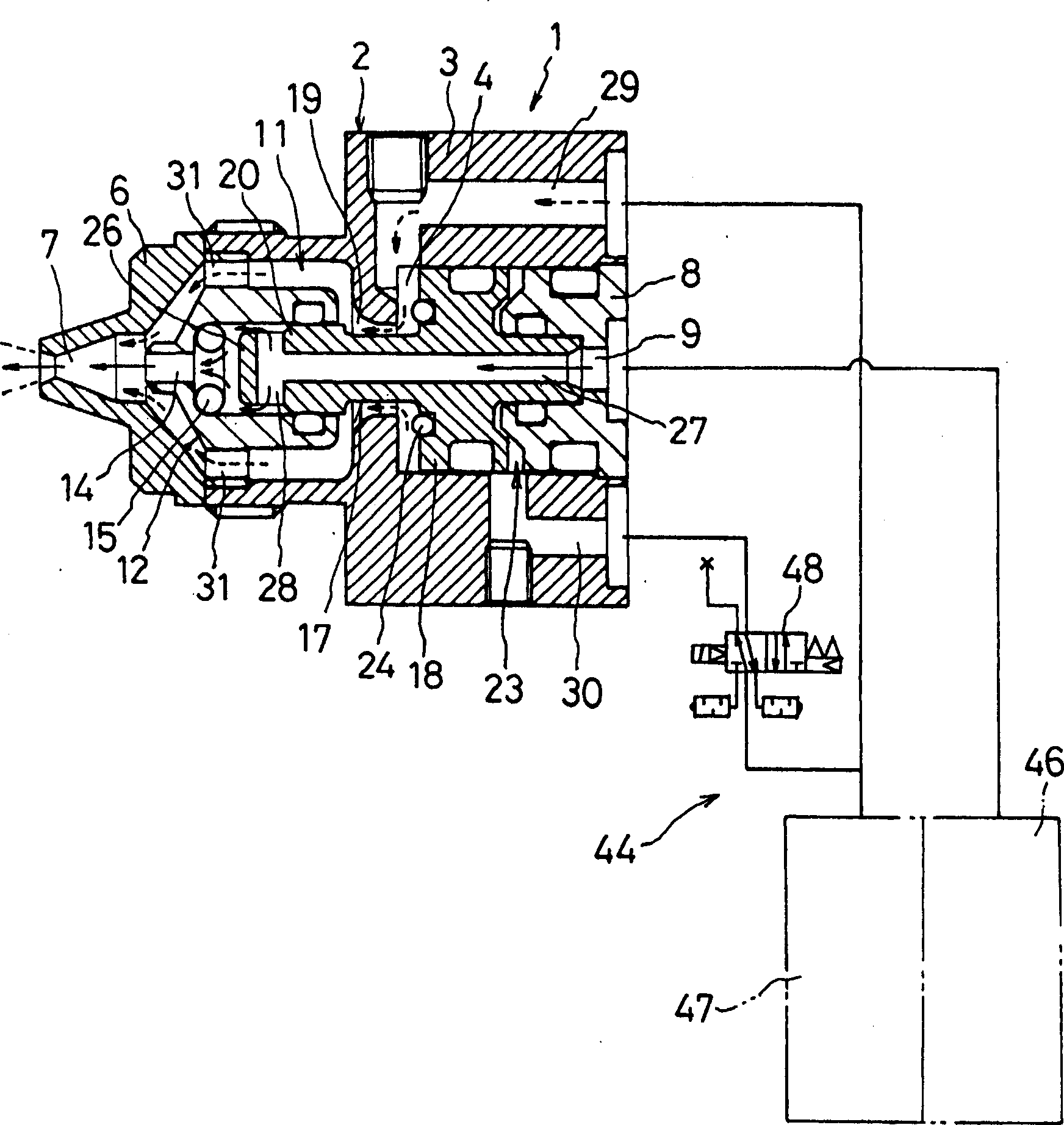

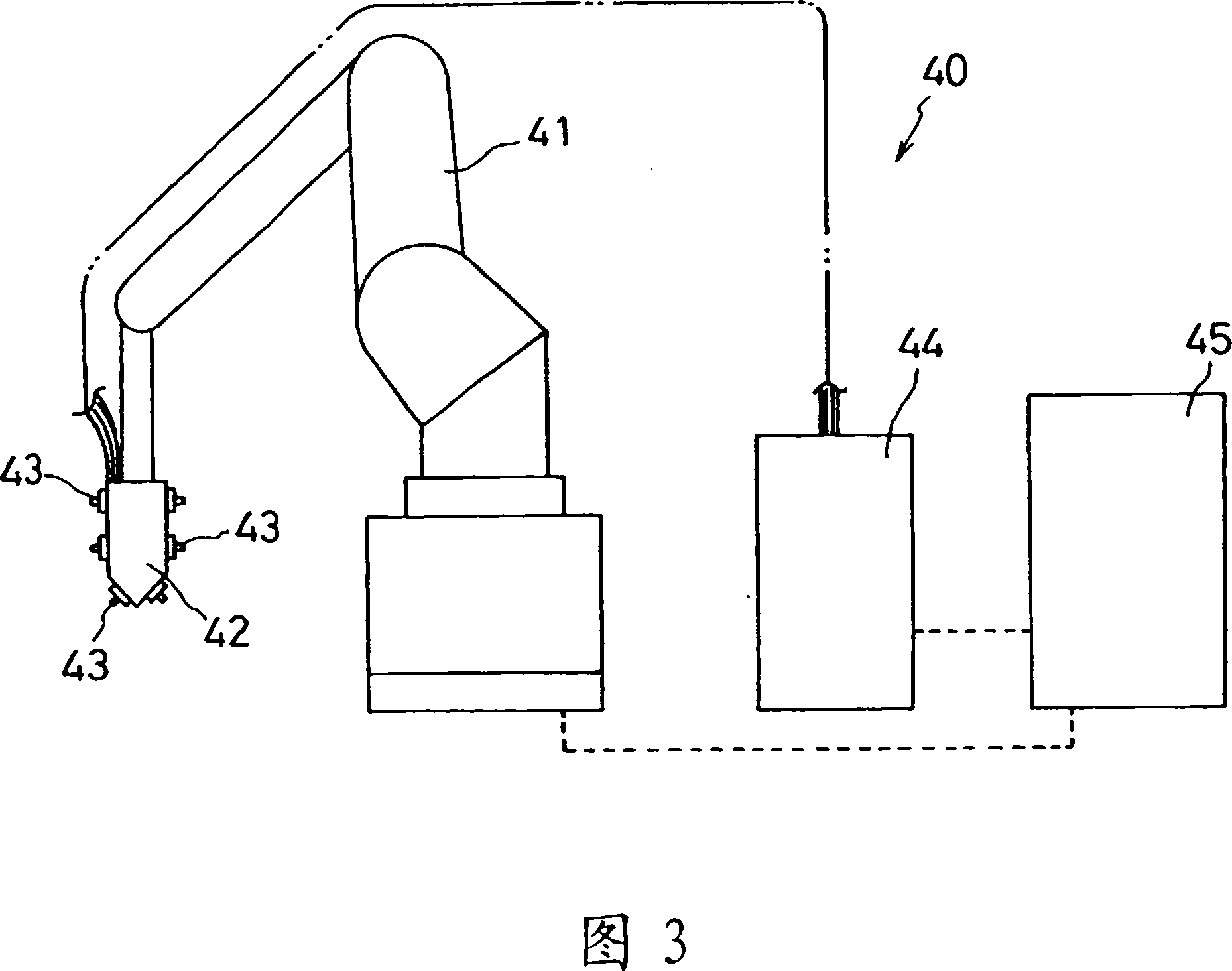

[0049] Embodiments of the present invention will be described below with reference to the drawings.

[0050] figure 1 is expressed in image 3 The longitudinal section view of the injection nozzle 1 used instead of the injection nozzle 43 in the shown injection system 40. Here, the manipulator 41 and the injection unit 42 etc. are omitted, and only the injection nozzle 1 and the control panel 44 and the connection between the two are shown. Fluid channels and gas flow channels. The body 2 of the spray nozzle 1 is formed by a body 3 of two-stage diameter, which is at the rear ( figure 1 A piston chamber 4 with a circular cross-section is formed on the axis, and a small-diameter cylindrical portion 5 protrudes from the front; and a cap ring (cap ring) 6 is coaxially connected with the cylindrical portion 5 of the main body 3 , the front end has a spray hole 7 with a thin head. The rear of the piston chamber 4 has a through hole 9 along the axis, which is closed by a piston ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com