Welding-performance testing and tester for solar battery and its assembly

A technology for solar cells and welding performance, used in welding equipment, manufacturing tools, metal processing equipment, etc., can solve problems affecting the reliability of power output components, welding area detection, and increasing series resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

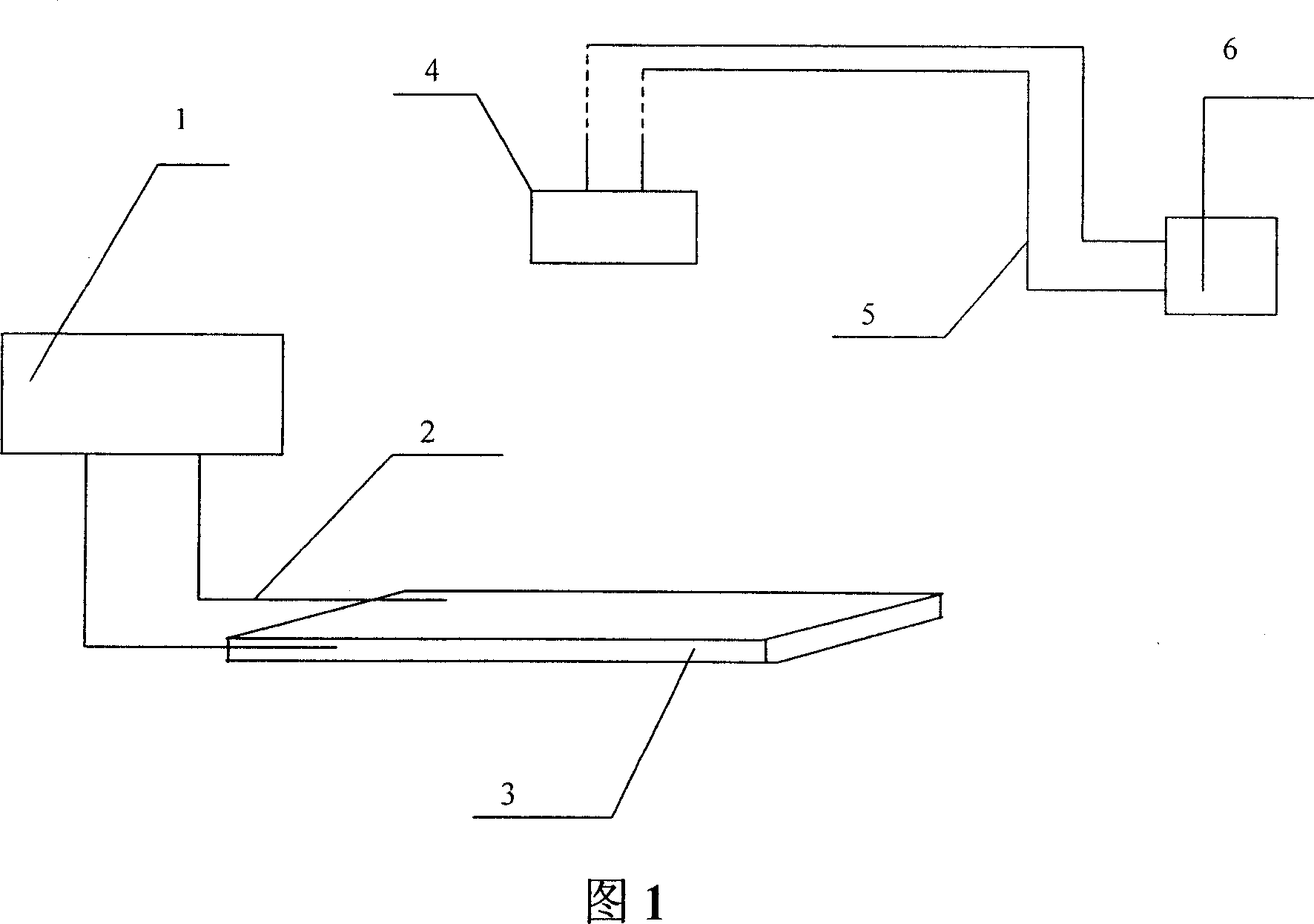

[0010] The present invention will be further described below in conjunction with drawings and embodiments.

[0011] A solar cell and its component welding performance testing process proposed in the first embodiment of the present invention, passes a certain amount of current to the solar cell or component to change the temperature of the welding area; if the welding is not good, the contact resistance will be large, The temperature change is large, so by collecting the data of temperature change, the welding performance parameters can be obtained by image processing and data processing and analysis software in the computer.

[0012] As shown in Figure 1, the solar cell and its component welding performance tester dedicated to the first embodiment is composed of a current and voltage controller 1, a wire 2, an infrared thermometer 4 and a computer 6, and the current and voltage controller 1 passes through the wire 2 is connected to the solar cell or component 3; the infrared t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com