Multiple-metal reforming catalyst and its production

A reforming catalyst and catalyst technology, applied in the direction of naphtha catalytic reforming, etc., can solve the problem of high cracking activity, and achieve the effects of improving aromatics selectivity, inhibiting cracking activity, and reducing carbon deposits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of the catalyst provided by the invention comprises molding the alumina carrier, then preparing the soluble salt of the compound containing VIII group metal, the compound containing VIIB group metal, magnesium and titanium into an impregnating solution, impregnating the alumina carrier, and After impregnation, the solid is dried and roasted.

[0020] The compound containing Group VIII metal is preferably platinum-containing compound, the compound containing Group VIIB metal is preferably rhenium-containing compound, and the soluble salts of magnesium and titanium are preferably chloride, nitrate or oxalate of magnesium and titanium respectively. The titanium mentioned in the catalyst can also be introduced in the form of titanium oxide when the carrier is formed, and the magnesium-containing compound selected when preparing the impregnation solution can also be magnesium hydroxide, magnesium bromide or magnesium iodide.

[0021] The platinum-conta...

example 1

[0030] Catalysts described in the present invention are prepared.

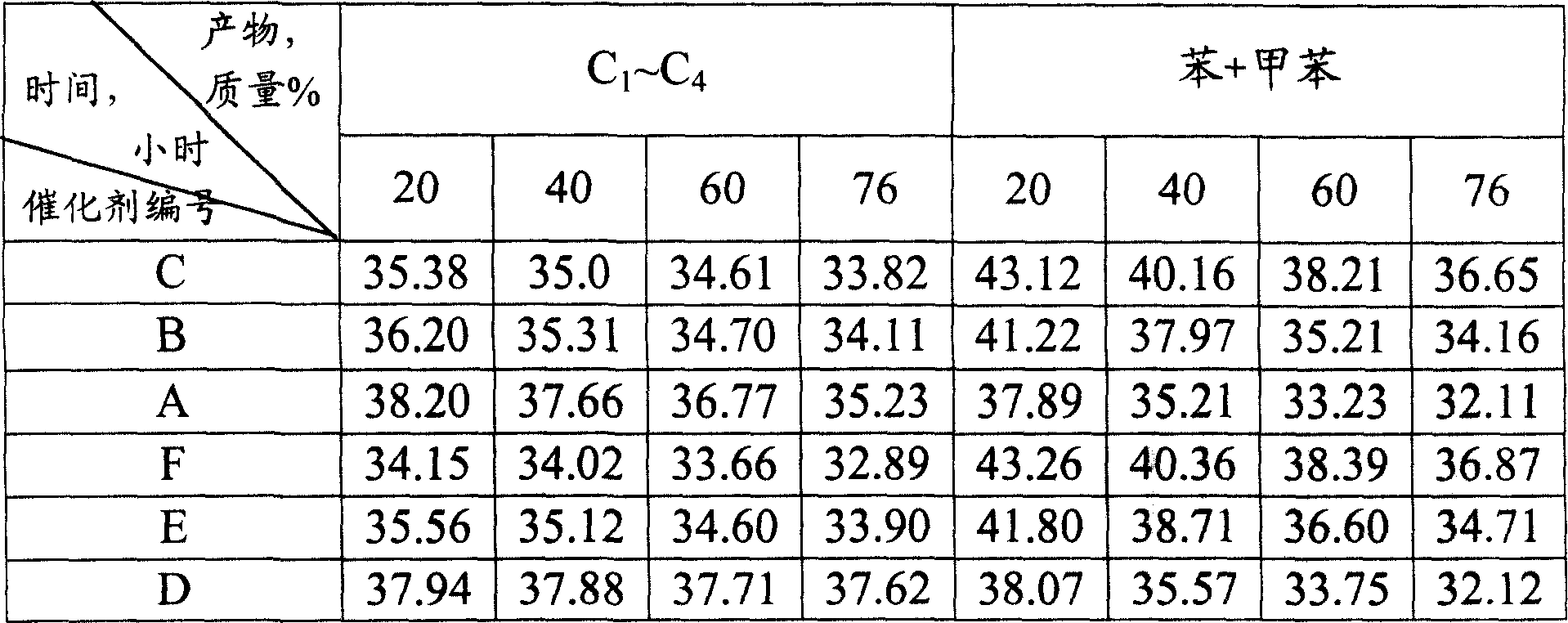

[0031] Get 60 grams of industrial strip-shaped γ-alumina carriers (produced by Changling Catalyst Factory), and make impregnation solution with chloroplatinic acid, titanium trichloride, perrhenic acid, magnesium chloride and hydrochloric acid (analytical pure), so that the impregnation solution contains Pt 0.22%, Ti 0.12%, Re 0.58%, Mg 0.2%, Cl 1.8% (all relative to the mass of dry alumina), the liquid / solid volume ratio is 1.9. Immerse at 25°C for 24 hours, filter, and dry at 60°C 24 hours, dry at 120°C for 12 hours, and bake for 4 hours under the conditions of 500°C in dry air and a gas / agent volume ratio of 700. Then, under the conditions of 480°C and gas / agent volume ratio of 500, use H 2 After reduction for 4 hours, catalyst C was prepared, and 0.10% (relative to the mass of the catalyst) hydrogen sulfide was added into the hydrogen flow at 425° C. for presulfurization. The composition of catalyst C is ...

example 2

[0033] Catalyst F is prepared by the method of example 1, and difference is that when preparing impregnating solution, contain Pt0.25%, Ti 0.14%, Re 0.30%, Mg 0.5%, Cl 1.8% (all with respect to dry basis alumina in impregnating solution) quality), the composition of the prepared catalyst F is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com