Method and device for gasifying water

An aerator and gas technology, applied in mixing methods, distribution devices, transportation and packaging, etc., can solve the problems of foam formation temperature, fluctuation, etc., achieve high release speed, and avoid complete failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

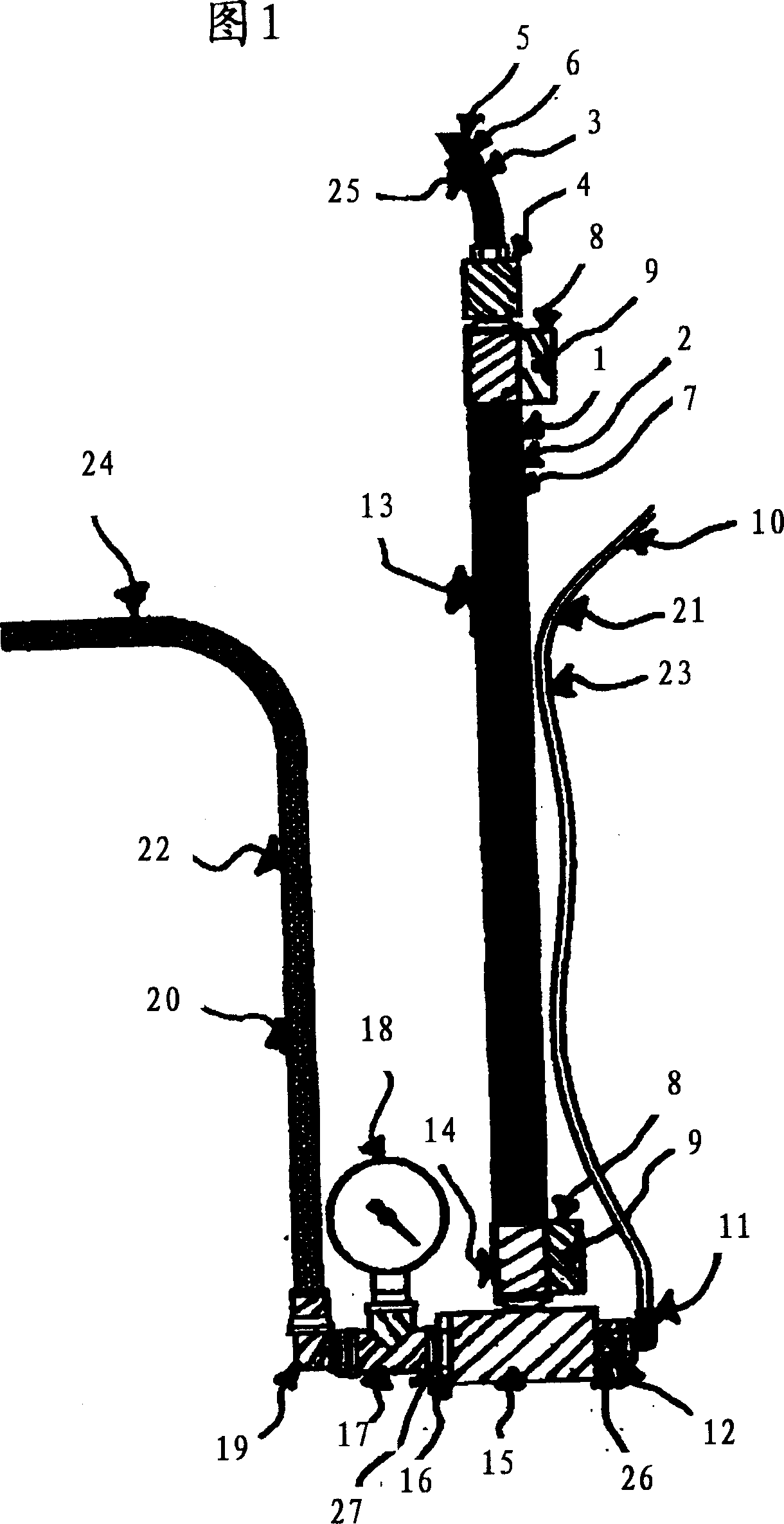

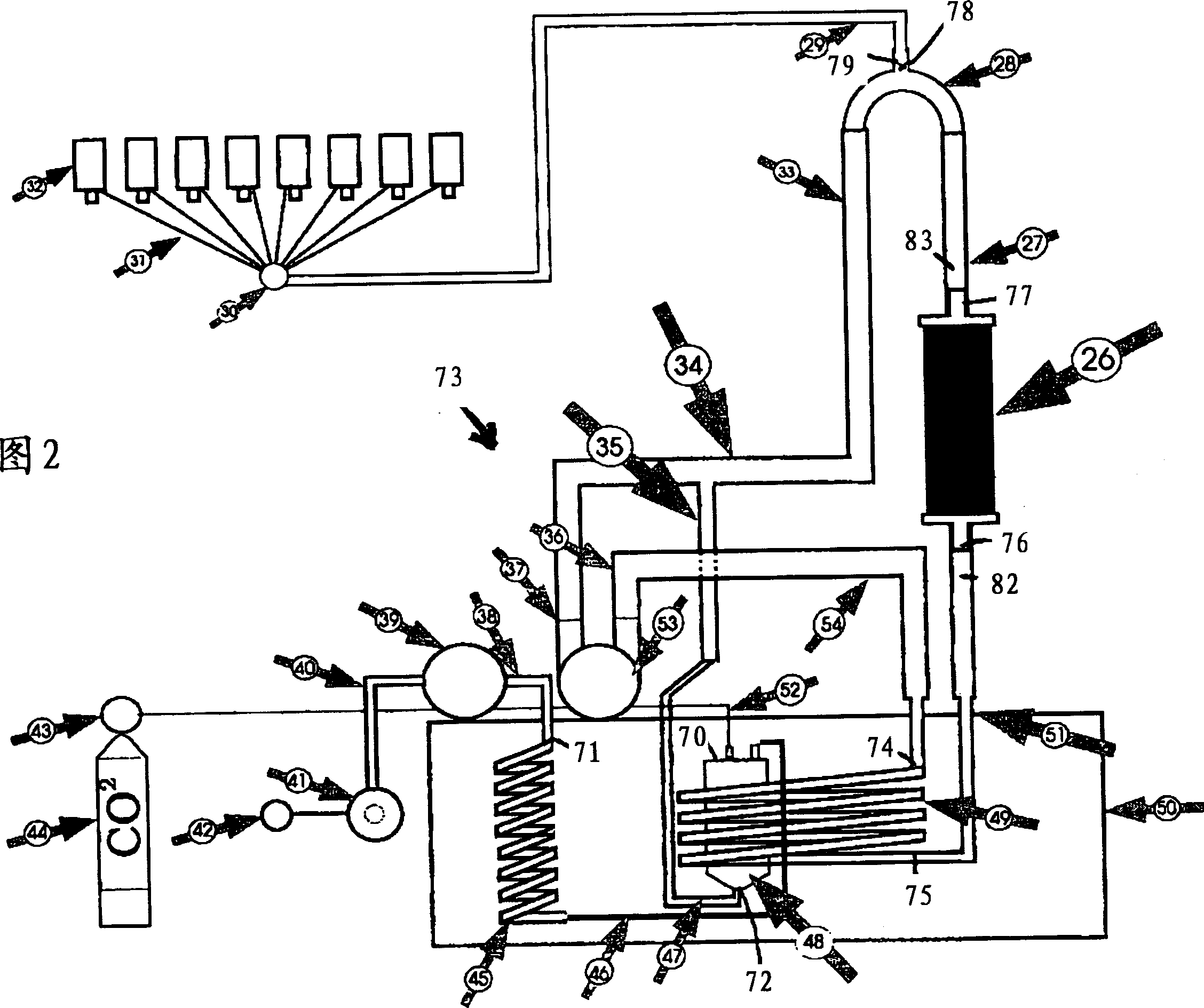

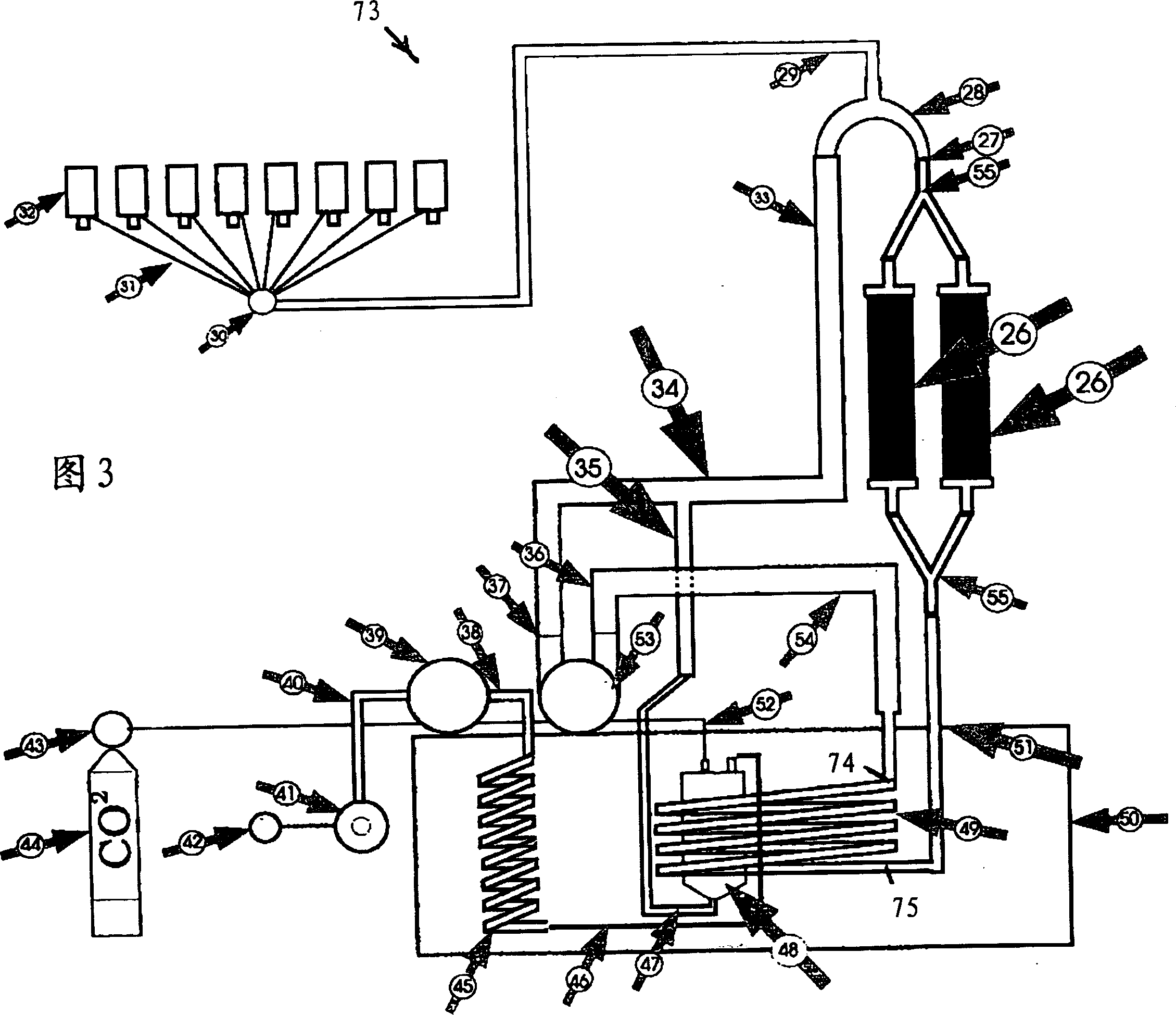

[0026] The device used to add gas to the liquid mainly includes a CO 2 When aerated, it is defined as the aerated container of the carbonation container 48, one when using CO 2 The in-line aerator and pressure lift pump 39 , gas supply 44 , bleed point 32 , housing 50 , first cooler 45 and second cooler 49 are defined as in-line carbonator 26 when aerated. The first cooler 45 is connected to the upper closure cover 70 of the carbonation vessel 48 through the connection pipe 46 , this cover has a channel extending into the interior cavity of the carbonation vessel 48 . In this cavity, the cold water supplied to the carbonation container through the connection pipe 46 is mixed with the gas supplied from the gas supply device 46 to the inside of the carbonation container 48 through the supply pipe 52 and the upper closure cap 70 .

[0027] The first cooler 45 is connected at its upper end 71 remote from the connecting pipe 46 to the inlet pipe 40 , through which liquid is suppli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com