Method for breaking wall of spirullina princeps

A technology of spirulina and spirulina powder, applied in the field of spirulina, can solve the problems of low wall breaking rate, difficult to achieve ideal breaking effect, etc., and achieve the effect of increasing intestinal absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

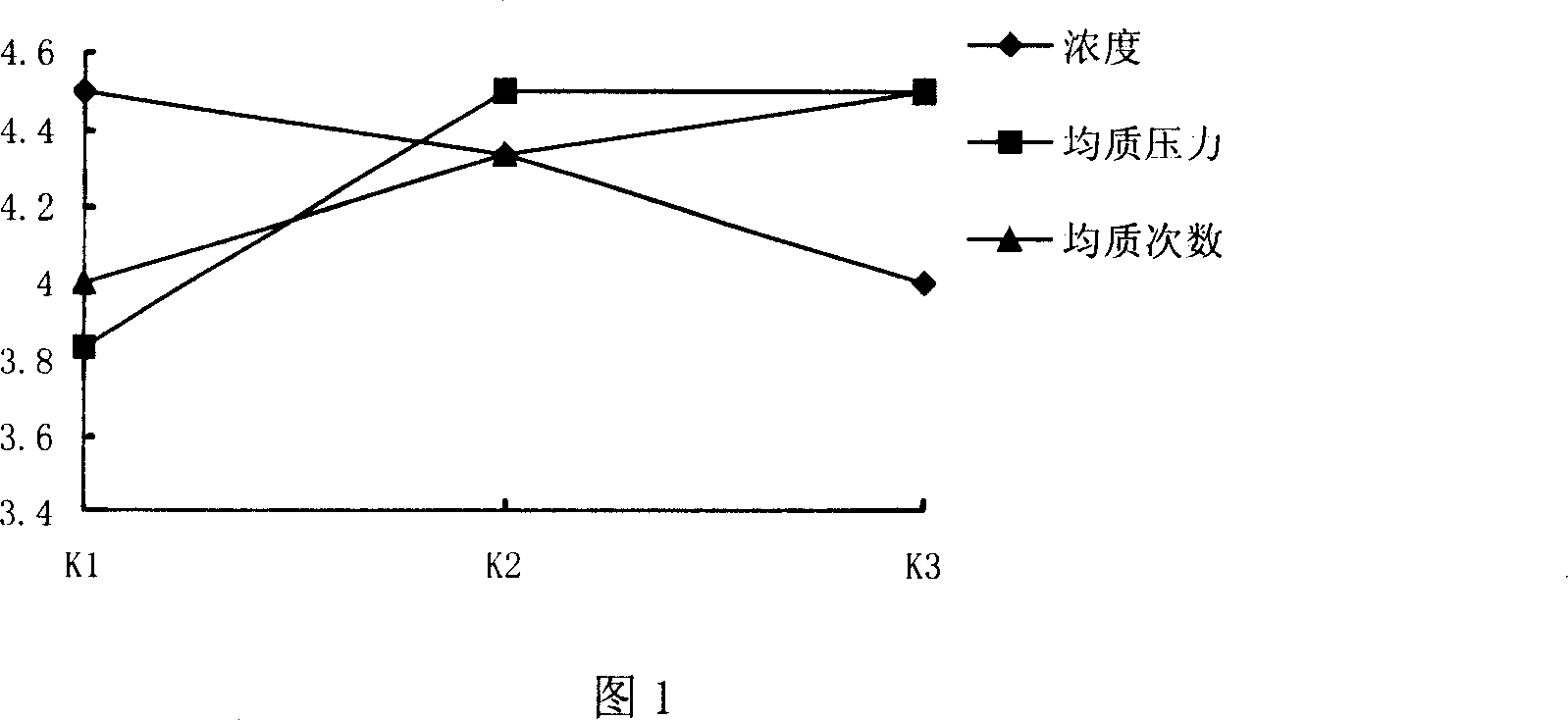

[0025] Add water to the dark green spirulina powder to prepare a spirulina solution with a concentration of 11%, add lysozyme to the spirulina solution for enzymatic hydrolysis, the dosage of lysozyme is 100IU / mL, the dissolution time is 3h, and the temperature is 45°C. The spirulina solution after enzymatic hydrolysis was homogeneously crushed in a homogenizer, the homogenization pressure was 30KPa, and homogenized 3 times. See Table 1 enzymatic hydrolysis-homogeneous wall breaking factor level table, and the analysis of orthogonal test results is shown in Figure 1.

[0026] factor name

[0027] According to the evaluation standard for the wall-breaking effect of spirulina, the wall-breaking liquid was observed with a microscope, and compared with the non-breaking liquid by counting method, the wall-breaking rate=(cell number of the wall-breaking liquid / cell number of the non-breaking liquid)×100%. 5 points for 90%, 4 points for 70%-80%, 3 points for 60%-70%, 2 poin...

Embodiment 2

[0029] Similar to Example 1, the difference is that the spirulina powder is added with water to form a 7% spirulina solution, and lysozyme is added to the spirulina solution for enzymolysis. The consumption of lysozyme is 200IU / mL, and the dissolution time is 4h. The temperature is 50°C. The spirulina solution after enzymatic hydrolysis was homogeneously crushed in a homogenizer, the homogenizing pressure was 40KPa, and homogenized twice, see Table 1 enzymatic hydrolysis-homogeneous wall breaking factor level table.

Embodiment 3

[0031] Similar to Example 1, the difference is that the spirulina powder is added with water to form a 15% spirulina solution, and lysozyme is added to the spirulina solution for enzymatic hydrolysis. The consumption of lysozyme is 300IU / mL, and the dissolution time is 2h. The temperature was 55°C. The spirulina solution after enzymatic hydrolysis was homogeneously crushed in a homogenizer, the homogenization pressure was 50KPa, and homogenized once.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com