Omnibearing full automatic binding machine

A binding machine, fully automatic technology, applied in binding and other directions, can solve the problem that the transmission flexibility, stability and accuracy cannot meet the binding requirements, and achieve the effect of saving layout space, reducing weight, and flexible transmission

Active Publication Date: 2007-04-11

北京亚博通科技发展有限公司

View PDF2 Cites 27 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, since the rotary mechanism still adopts the form of a cylindrical cam, the flexibility, stability and precision of its transmission can no longer meet the increasing binding requirements.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

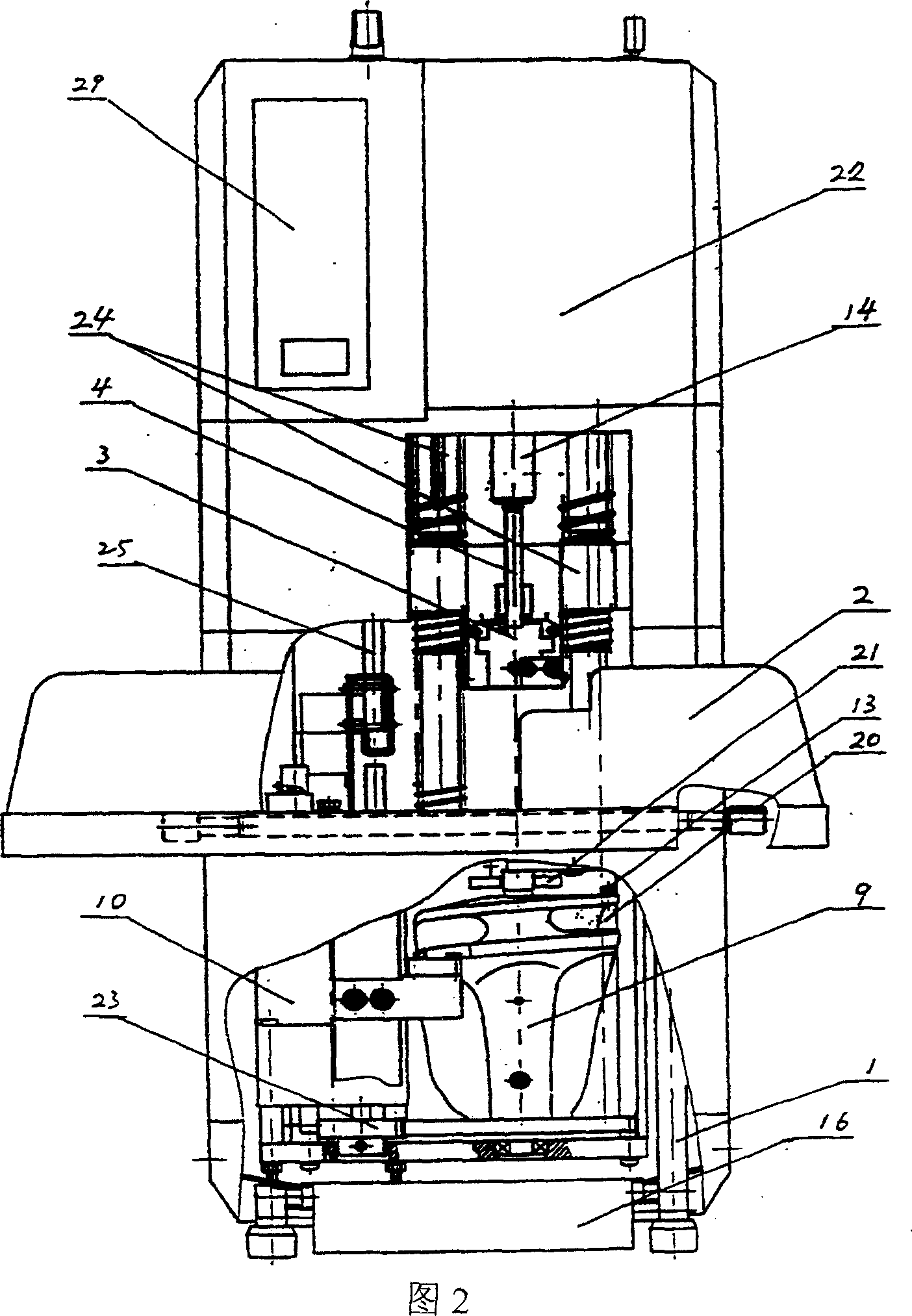

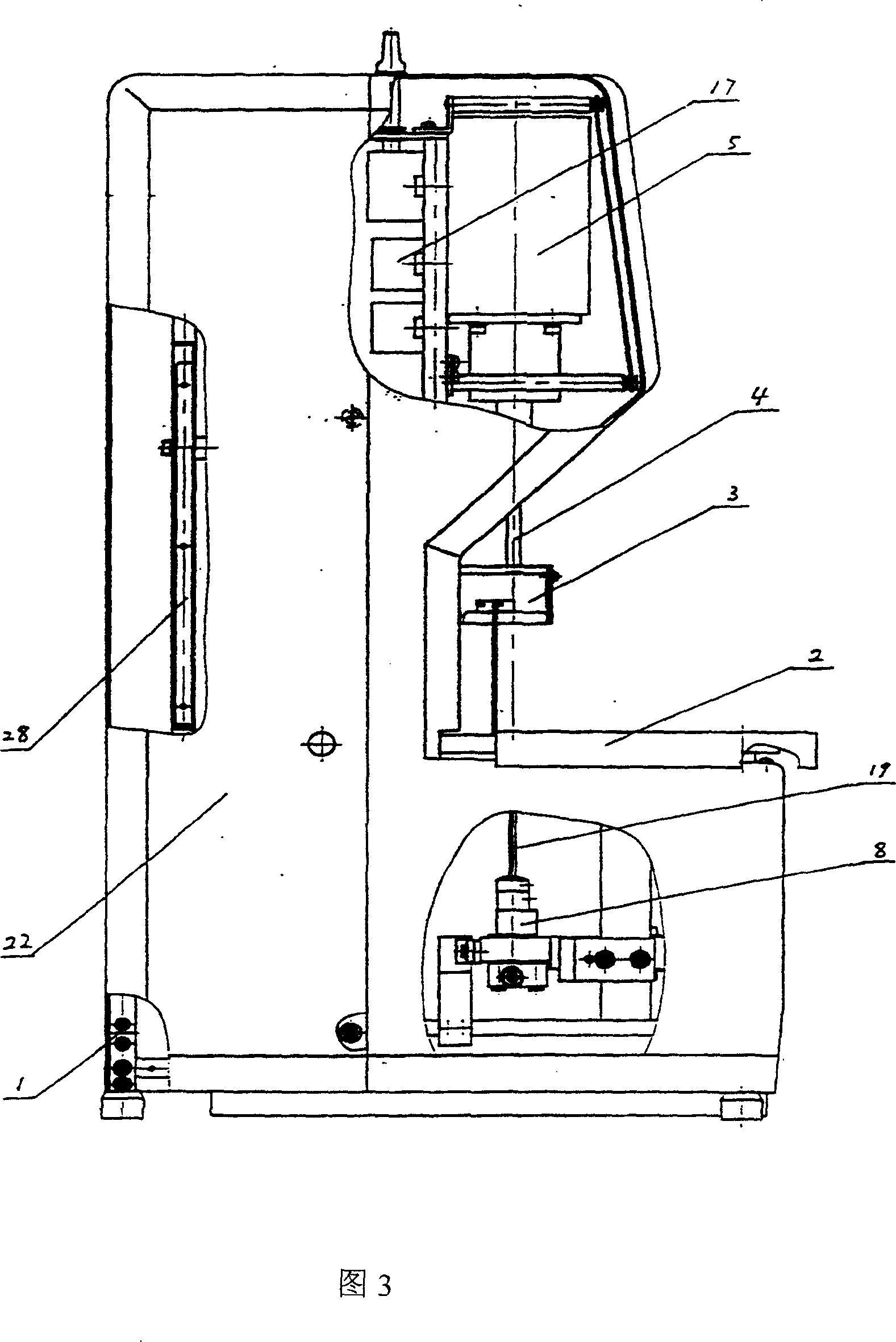

[0050] Firstly, each component of the present invention will be described in detail with reference to the accompanying drawings, and then the overall structure will be further described in conjunction with the accompanying drawings.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The omnibearing full automatic binding machine consists of a frame, a casing, a bench, a paper holding mechanism, a hole drilling mechanism, a tube setting mechanism, a tube cutting mechanism, a rotary tube feeding mechanism, a pressing and riveting mechanism and a control circuit device mainly. It has also bearer fixed behind the bench, two guide shafts on the bearer, punching motor, shifting motor, walking motor, upper pressing spring, lower pressing spring and other parts. It has small size, light weight, smooth driving, accurate position and other advantages and may be used widely in binding various kinds of files.

Description

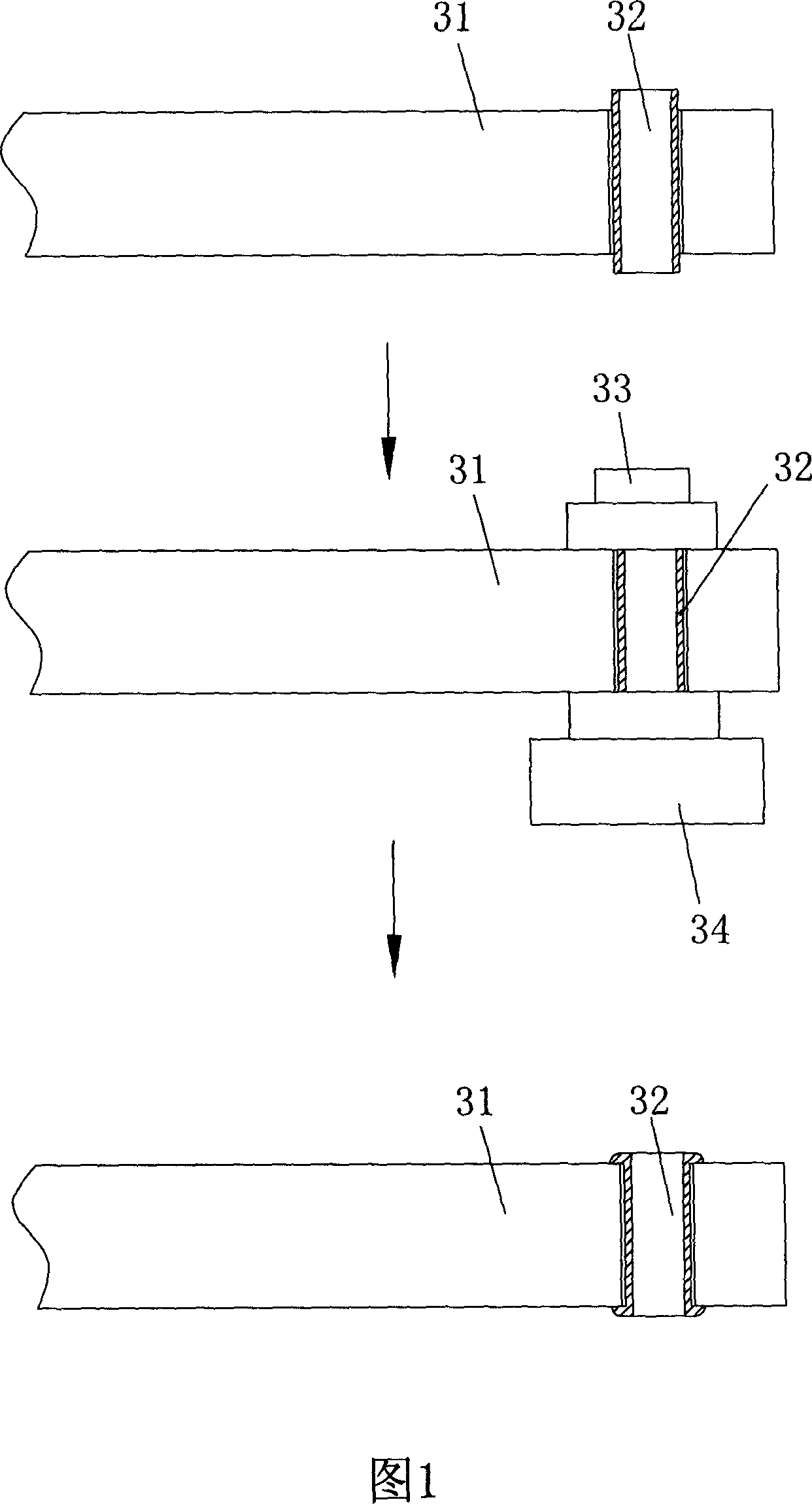

technical field [0001] The invention relates to a fully automatic file binding machine, more precisely a fully automatic file binding machine which uses a binding tube for pressure riveting binding. technical background [0002] At present, the riveting binding method is generally used for the binding of reconciliation pages, bills, files and other papers. It generally includes several process steps such as punching, cutting, feeding, and riveting. The principle is shown in Figure 1. After the loose leaf 31 is compressed and the binding holes are drilled, insert a certain length of synthetic resin tube 32, and use the upper heating mold 33 and the lower heating mold 34 to push the upper and lower ends of the synthetic resin tube to melt and deform them into flanges respectively. Thus, the clamp binding of the paper is completed. [0003] In order to realize the above-mentioned purpose of automatic binding, Chinese patent CN02245635.X just discloses a kind of " fully automat...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B42B5/00B42B5/02

Inventor 周岩闫殿杰范宗民

Owner 北京亚博通科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com