Mercury alloy for low gas pressure discharge lamp

A technology of gas discharge lamps and amalgam, which is applied to the parts of gas discharge lamps, etc., can solve the problems of light output drop, drop, drop to 0.3Pa, or even lower, and low output efficiency, and achieve the goal of improving stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

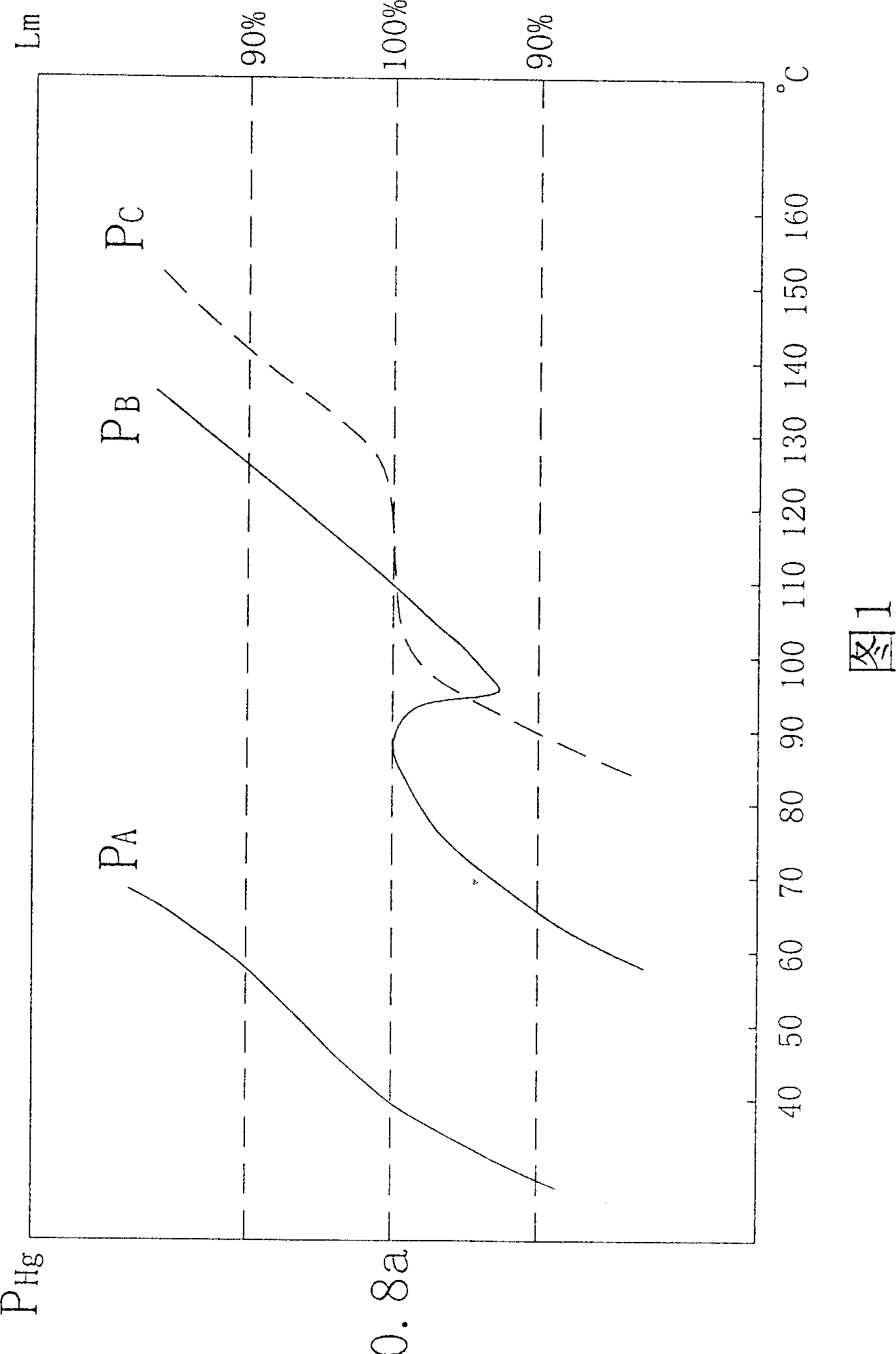

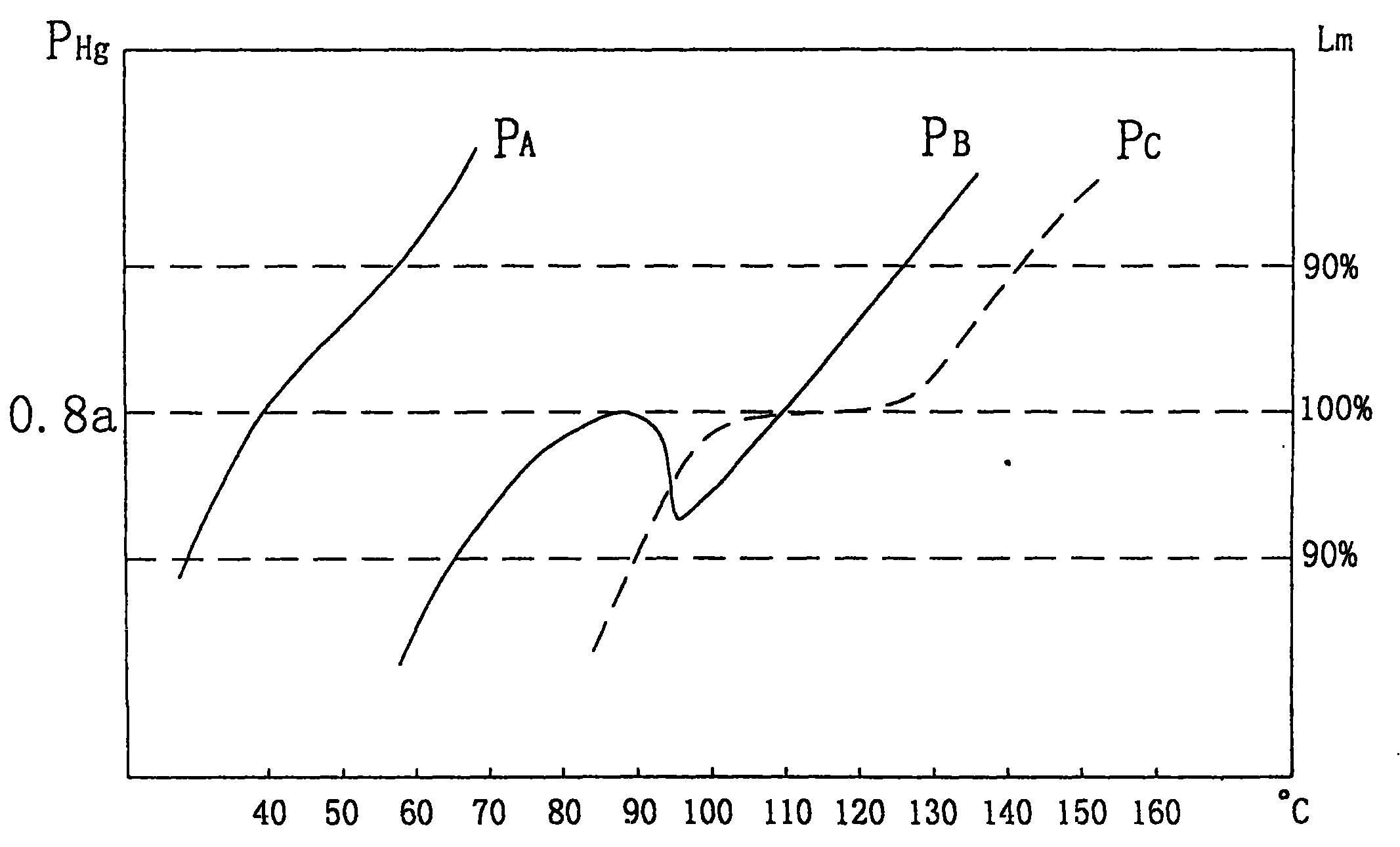

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: Indium-lead-tin amalgam according to mass ratio (m / m) proportioning In:Pb:Sn:Hg=38:20:38:4, is made into pellet through melting drop, in working temperature range 100-130 ℃ has a constant mercury vapor pressure and stable light output. It is used in PAR lamps with built-in compact fluorescent lamps of 5-13w. High light output with significantly better consistency than bismuth-indium amalgam.

Embodiment 2

[0015] Embodiment 2: Indium-lead-tin amalgam according to the mass ratio (m / m) In:Pb:Sn:Hg=36:16:44:2, is made into pellets through melting and dropping, and is applied in 13-20w built-in compact fluorescent lamps Among the PAR lamps, the average luminous efficacy is high and the consistency is good.

Embodiment 3

[0016] Embodiment 3: Indium-lead-tin amalgam according to mass ratio (m / m) In: Pb: Sn: Hg=32: 18: 47: 3, through melting and dripping, make pellets, apply in 13-20w built-in compact fluorescent lamp Among the PAR lamps, the average luminous efficacy is high and the consistency is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com