Joined body of different materials of steel material and aluminum material and method for joining the same

A technology of welding materials and aluminum materials, applied in the direction of welding/welding/cutting items, manufacturing tools, welding equipment, etc., can solve the problems of increasing welding costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0268] Test steels having the chemical compositions (mass %) shown in Table 1 were melted. The test steel slabs were rolled to obtain steel products with a thickness of 1.2 mm. The steel is annealed by a continuous annealing process using a temperature between about 500°C and 1000°C. Clean annealed steel by washing with water or oil. The cleaned steel was tempered to obtain high tensile strength steel of grade 980MPa. Commercially available aluminum alloy plates of A6022 (type 6000) with a thickness of 0.1 mm and 1.6 mm were used as test aluminum materials.

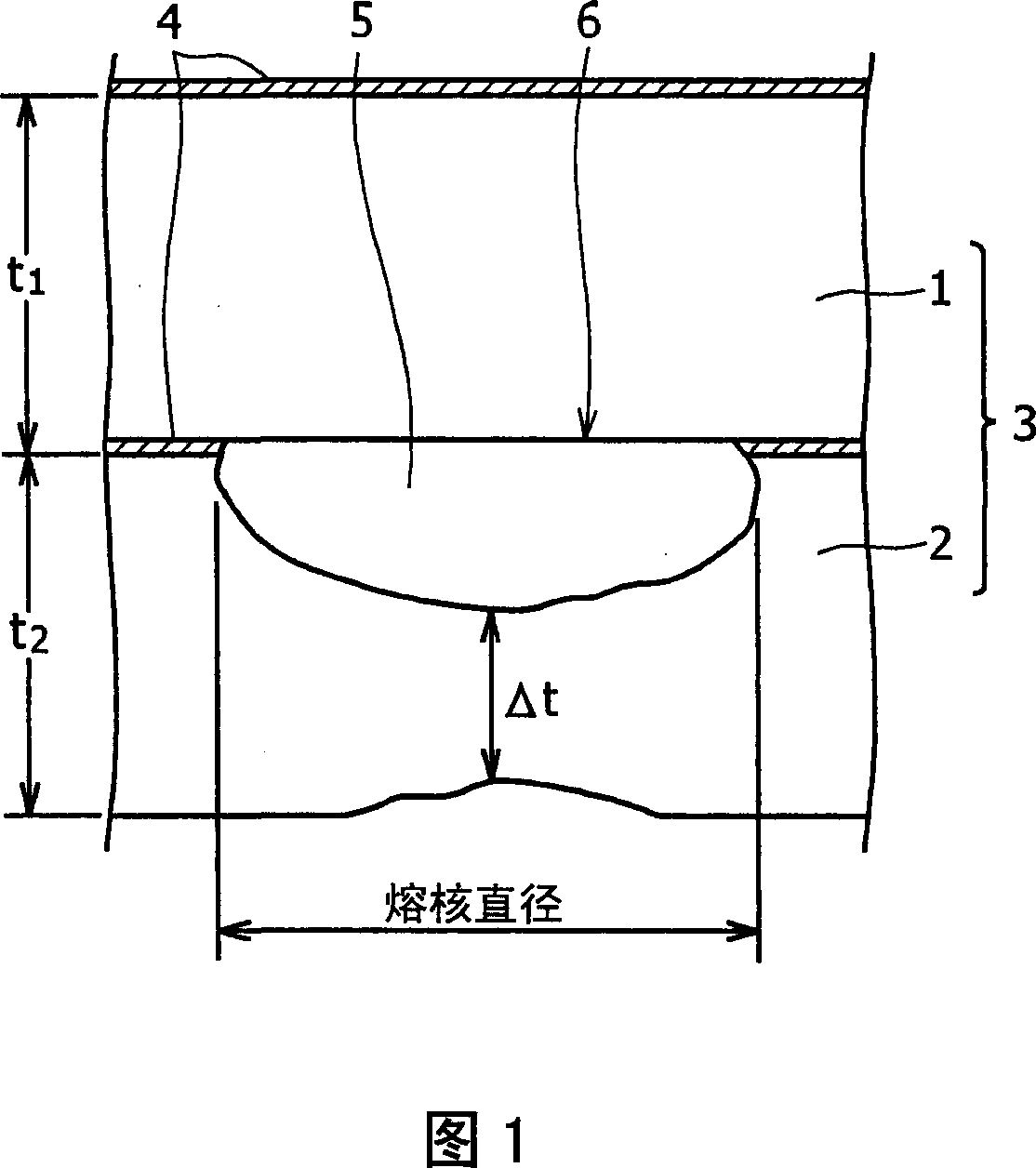

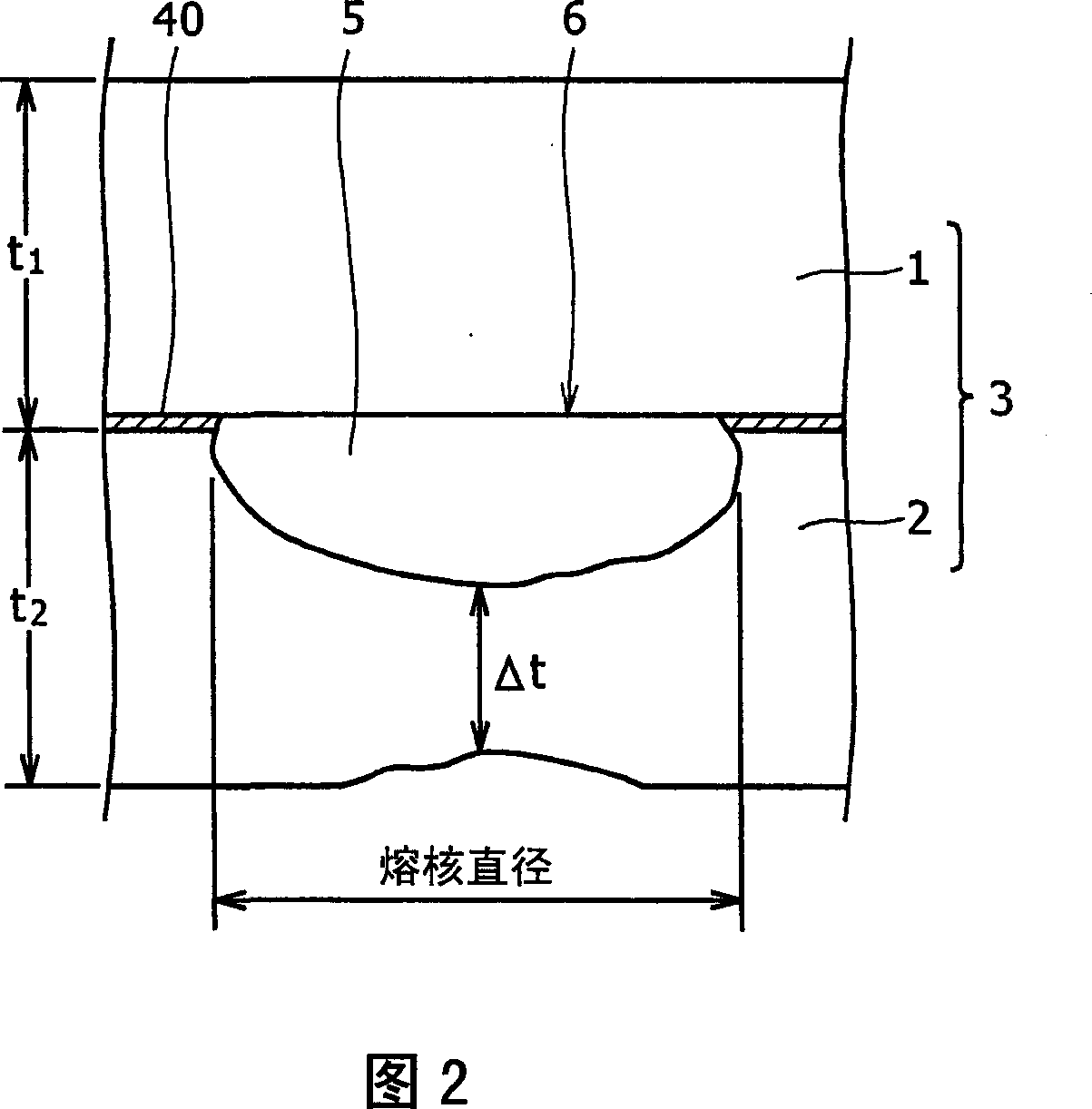

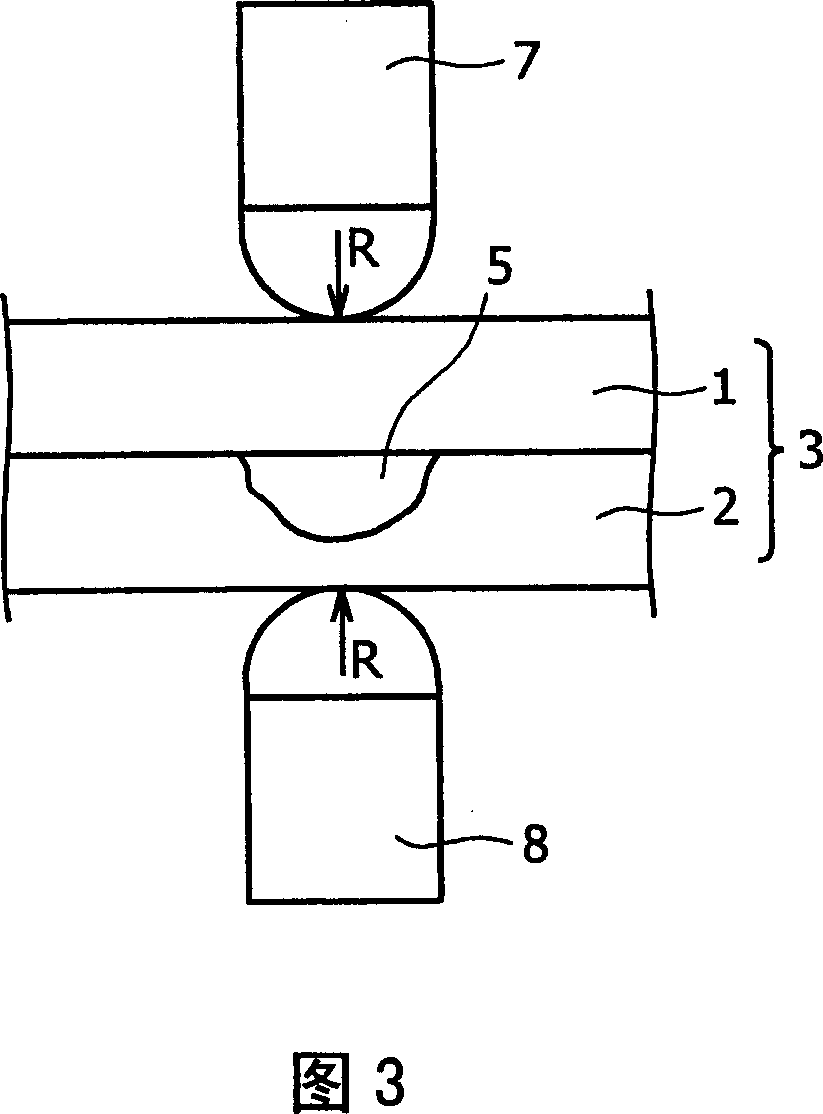

[0269] The steel material and the aluminum alloy plate are cut into a specimen having the shape of a transverse tensile strength test sample, and the steel material and the aluminum alloy plate specimen are welded together by spot welding to obtain a steel-aluminum welding material. The DC contact spot welding tester is used for spot welding. Combining the thickness t of each aluminum material 2 Optionally determine ...

Embodiment 2

[0286] Test steels having the chemical compositions (mass %) shown in Table 1 were melted. The test steel slabs were rolled to obtain steel products with a thickness of 1.2 mm. The steel is annealed by a continuous annealing process using a temperature between about 500°C and 1000°C. Clean annealed steel by washing with water or oil. The cleaned steel was tempered to obtain high tensile strength steel of grade 980MPa. Commercially available aluminum alloy plates of A6022 (type 6000) with a thickness of 0.1 mm (Tables 10, 11 and 12) and 1.6 mm (Table 12) were used as test aluminum materials. The steel plate (steel material) and the aluminum alloy plate (aluminum material) were cut into test pieces in the shape of transverse tensile strength test specimens specified in A3137, JIS, and tested by point welding under the welding conditions shown in Table 9. Welding The steel and aluminum alloy plate test pieces were welded together to obtain a steel-aluminum welding material.

...

Embodiment 3

[0304] Test steels having the chemical compositions (mass %) shown in Table 14 were melted. The test steel slabs were rolled to obtain steel products with a thickness of 1.2 mm. The steel is annealed by a continuous annealing treatment using a temperature between 800°C and 900°C. Clean annealed steel by washing with water or oil. The cleaned steel is tempered to adjust the strength of the steel to a suitable strength. A commercially available 1 mm thick A1050 aluminum alloy plate containing 0.05% Si and no Mn and a commercially available 1 mm thick A6022 aluminum alloy plate containing 1.10% Si and 0.07% Mn were used as test aluminum materials. The steel plate (steel material) and the aluminum alloy plate (aluminum material) are cut into test pieces having the shape of a transverse tensile strength test sample specified in A3137, JIS, and the steel material and the aluminum alloy plate are welded by spot welding The test pieces were welded together to obtain steel-aluminum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com