Embossed tufting needle

A tufting needle and needle handle technology, which is applied in the field of improved tufting needles, can solve the problems of wear through yarn grooves, limit the working life of tufting needles, miss empty grooves, etc., and achieve the effect of reducing wear loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

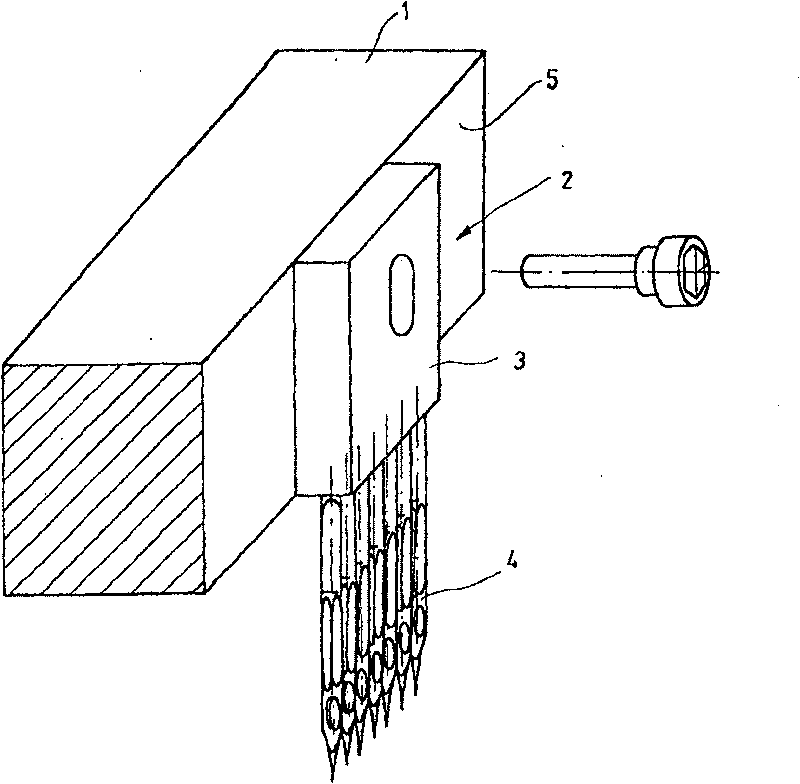

[0026] figure 1 A needle board 1 supporting a tufting module 2 is schematically shown. The tufting module 2 includes a main body 3 in which or on which a set of tufting needles is clamped. The main body 3 rests on the front side 5 of the needle plate 1 with flat flat sides. The tufting needles 4 are spaced parallel to each other and point downwards.

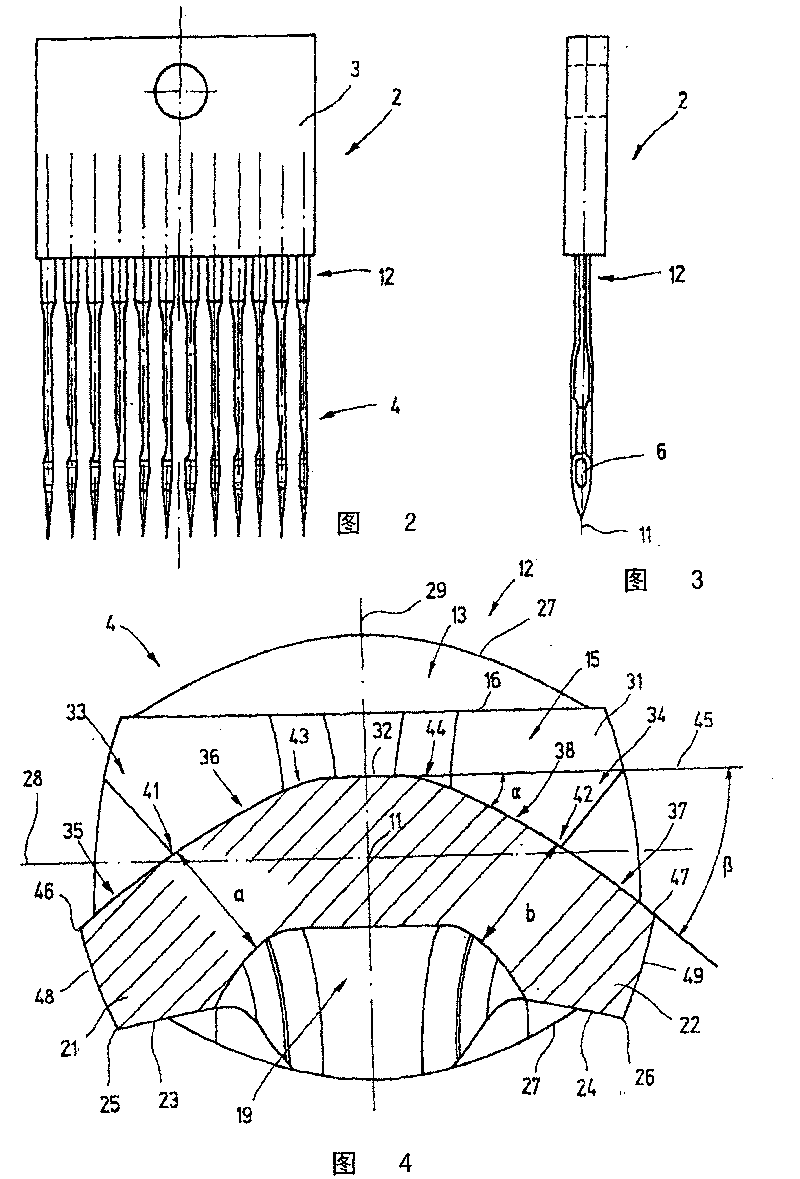

[0027] figure 2 and 3 The tufting modules 2 are shown respectively. like figure 2 As shown, the tufting needles 4 have the same structure and are flattened. They are clamped in the body 3 at their upper end. like image 3 As shown, their eyelets 6 are eg aligned with each other.

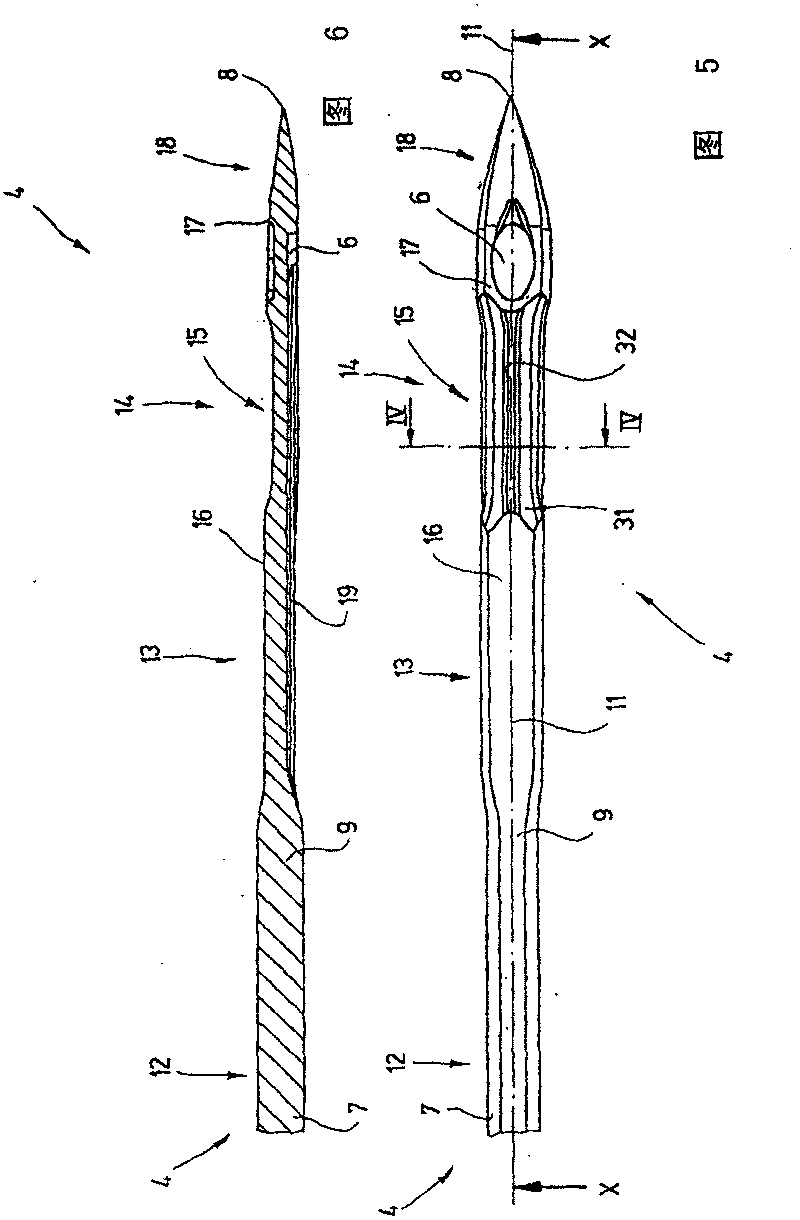

[0028] Figure 4 , 5 and 6 show the structure of a single tufting needle 4 . like Image 6 As shown, the tufting needle 4 has a needle body 7 constituting a shank 9 extending to a tip 8 marking the center of the shank 9 . A longitudinal axis 11 defining the longitudinal direction of the needle body 7 and the needle shaft 9 passes through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com