Process for producing natural stone composite plate

A processing technology and composite board technology, which is applied in the direction of stone processing tools, stone processing equipment, manufacturing tools, etc., can solve the problems of complex production process, high cost, unreasonable and scientific stone materials, etc., and achieve the effect of reducing costs and facilitating installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

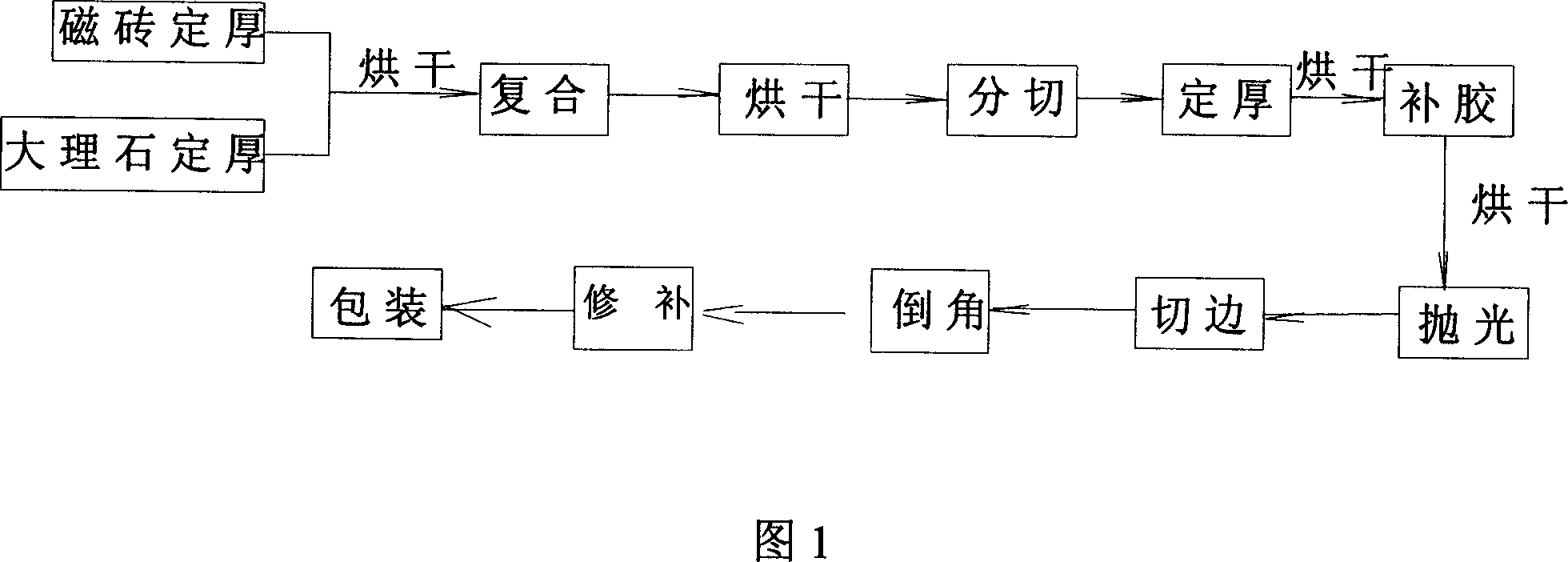

[0018] As shown in Figure 1, a kind of processing technology of natural marble composite board, this technology comprises the following steps:

[0019] (1) Cut the natural marble into 603×603 specifications, polish it to a thickness of 20mm, and smooth it, remove surface dust, sand, oil and other impurities, and dry to remove moisture;

[0020] (2) Glue on the upper and lower surfaces of the treated natural marble with a tile of 8mm thickness equal to the length and width of the marble (the tile is artificially synthesized with ordinary cement and other materials), compound it into a primary composite board, and let it stand for curing , use clamps to pressurize or jacks to pressurize evenly, so that the primary composite plate is pressurized evenly, and the pressure is controlled at 4700kg / m 2 ;Then place the primary composite board in a drying room at 120°C and heat it evenly for 3 hours, then cool it down to room temperature naturally;

[0021] (3) Use a splitting machine ...

Embodiment 2

[0025] A processing technique for a granite composite board, the technique comprises the following steps:

[0026] (1) Cut a natural granite into 603×603 specifications, polish it to a thickness of 20mm, and smooth it, remove surface dust, sand, oil and other impurities, and dry to remove moisture;

[0027] (2) Use glue on the upper and lower surfaces of the treated natural granite to glue a tile with a thickness equal to the length and width of the granite to form a primary composite board, let it stand and solidify, and use a clamp to pressurize or a jack to press evenly. Make the primary composite plate press uniformly distributed, and the pressure is controlled at 4700k / m 2 ; Curing at room temperature for 12 hours;

[0028] (3) Split the primary composite board from the middle granite layer with a splitting machine, so that the primary composite board becomes two identical composite boards. The composite board has two layers, one is a natural granite layer, and the other...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com