High precision intelligent platinum thermal resistance temperature sensor with correction function

A technology of temperature sensor and platinum thermal resistance, which is applied to thermometers, thermometers, instruments, etc. that use electric/magnetic elements that are directly sensitive to heat, can solve problems such as increasing system cost and increasing system complexity, and improve measurement accuracy. High precision, hot swap and automatic recognition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

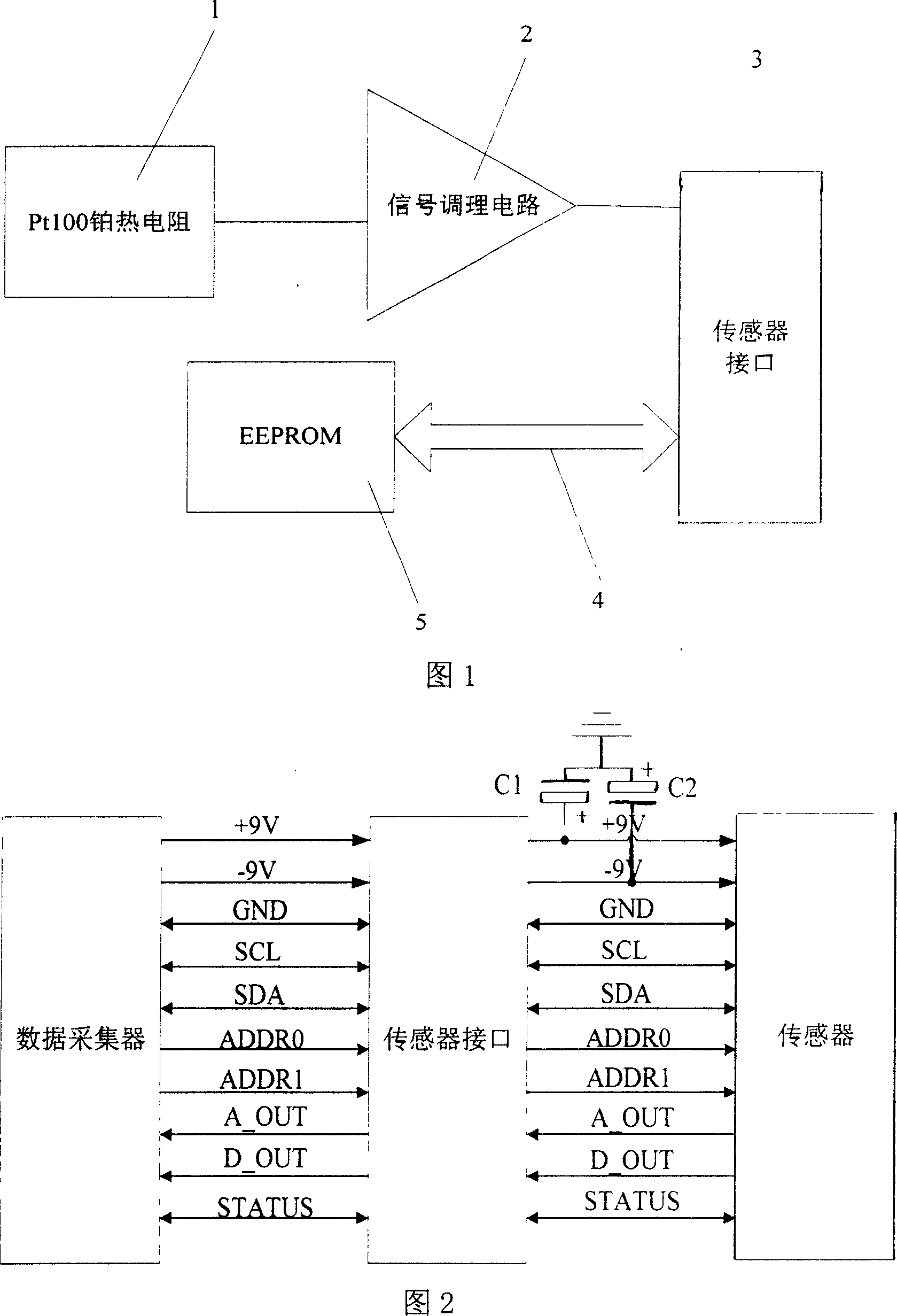

[0015] As shown in Figure 1: the platinum thermal resistance 1 of the present invention is connected to the sensor interface circuit 3 through the signal conditioning circuit 2; the EEPROM 5 is connected to the sensor interface circuit 3 through the I2C bus 4.

[0016] The platinum thermal resistance 1, the signal conditioning circuit 2, the sensor interface 3, and the EEPROM memory 5 are packaged into one, and the sensor interface circuit 3 is used as an output port connected to the data acquisition system, and is connected to the data acquisition system through a cable. The identity information, calibration information, and analog output level information of the platinum thermal resistance 1 are stored inside the EEPROM.

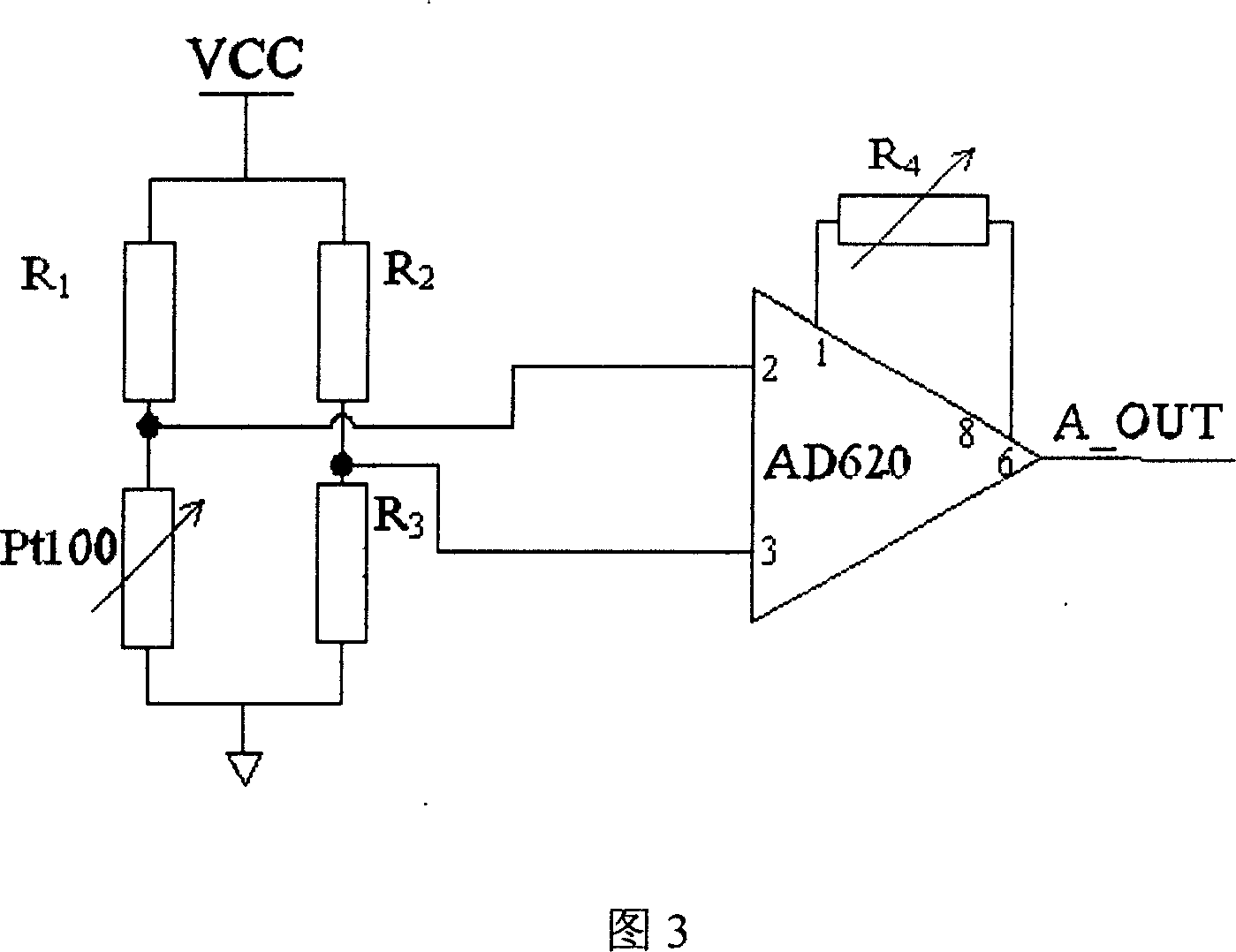

[0017] The definition of the sensor interface is as follows: +9V, -9V, GND are power transmission lines, SCL, SDA are I 2 Clock and data lines of the C bus. ADDR0 and ADDR1 are two address lines. A_OUT is an analog output signal line, and D_OUT is a digi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com