Solar battery assembly

A technology of solar cell components and batteries, which is applied to electrical components, circuits, photovoltaic power generation, etc., can solve the problems of reducing the effectiveness of solar cell chips, and achieve excellent weather resistance, improved protection functions, and long-term reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

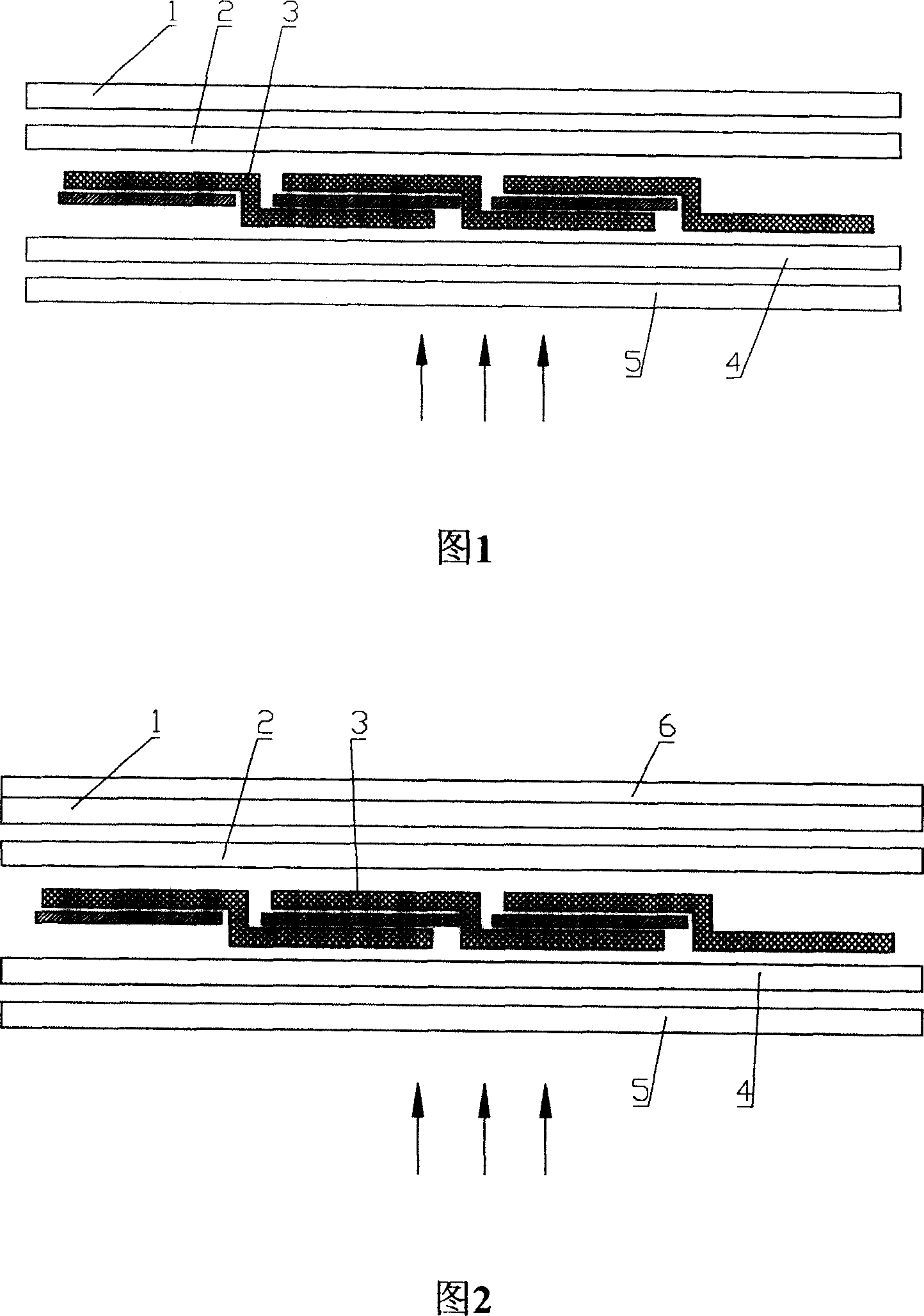

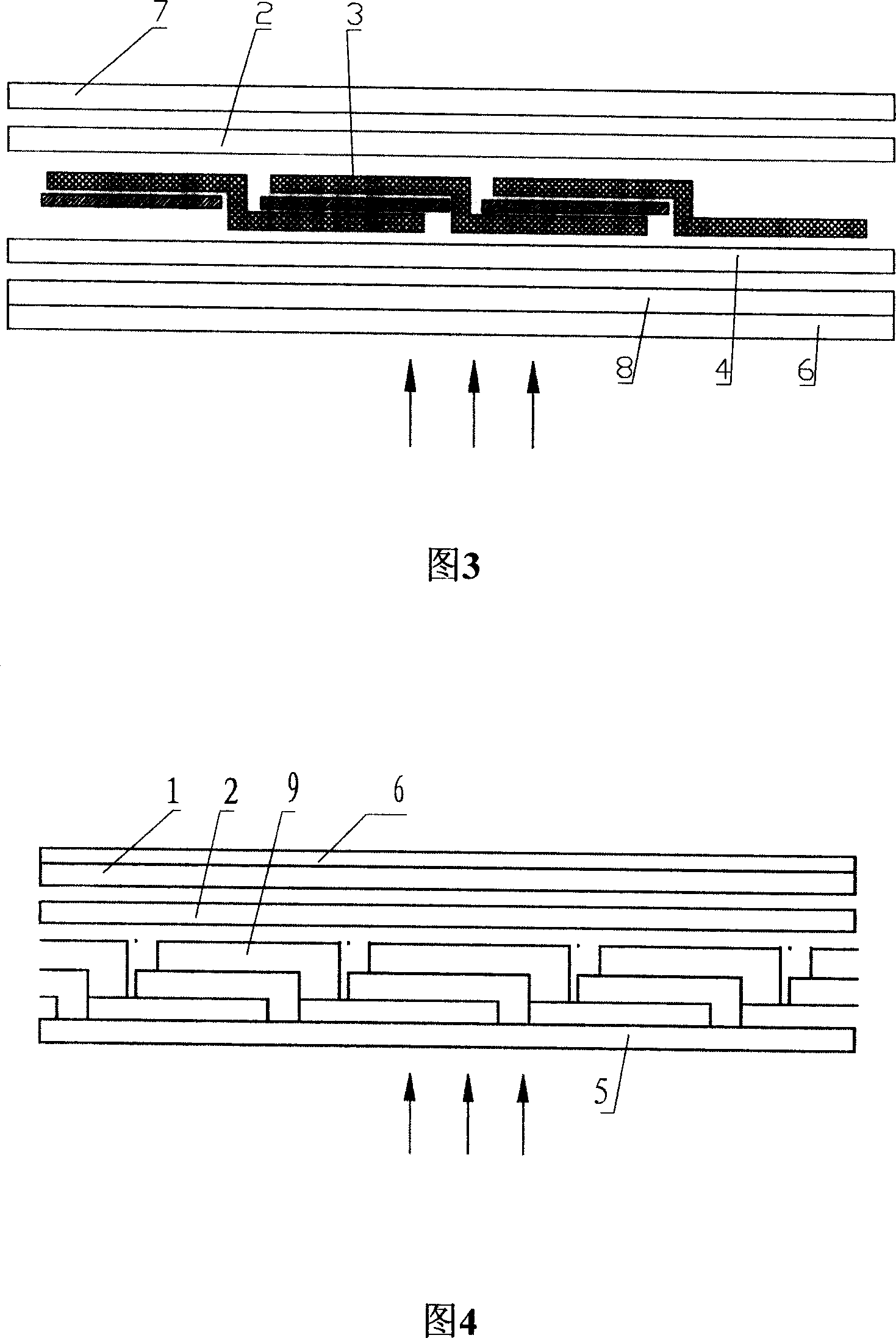

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0012] Fig. 2 is the first embodiment of the present invention, which consists of back protective film 1, lower surface EVA film 2, battery chip series group 3, upper surface EVA film 4, light-receiving surface glass 5, and sunlight is injected from light-receiving surface glass 5 , so that the cells connected in series group 3 generate electricity. The feature of this embodiment is that a layer of ceramic thin film 6 is compounded on the back protective film 1. The ceramic thin film 6 has the characteristics of low moisture permeability and low air permeability, and protects the solar cell module against moisture and oxidation.

[0013] The ceramic film 6 is a metal or non-metal inorganic compound film, which can be any one or more of metal or non-metal inorganic compounds such as silicon oxide, titanium oxide, aluminum oxide, silicon nitride...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com