Tire testing machine and axis misalignment measuring method for tire testing machine

一种测试机、轮胎的技术,应用在汽车轮胎测试、测量装置、轮胎零部件等方向,能够解决温度增加不恒定、温度分布不均匀、难以预料等问题,达到接触面积增加的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

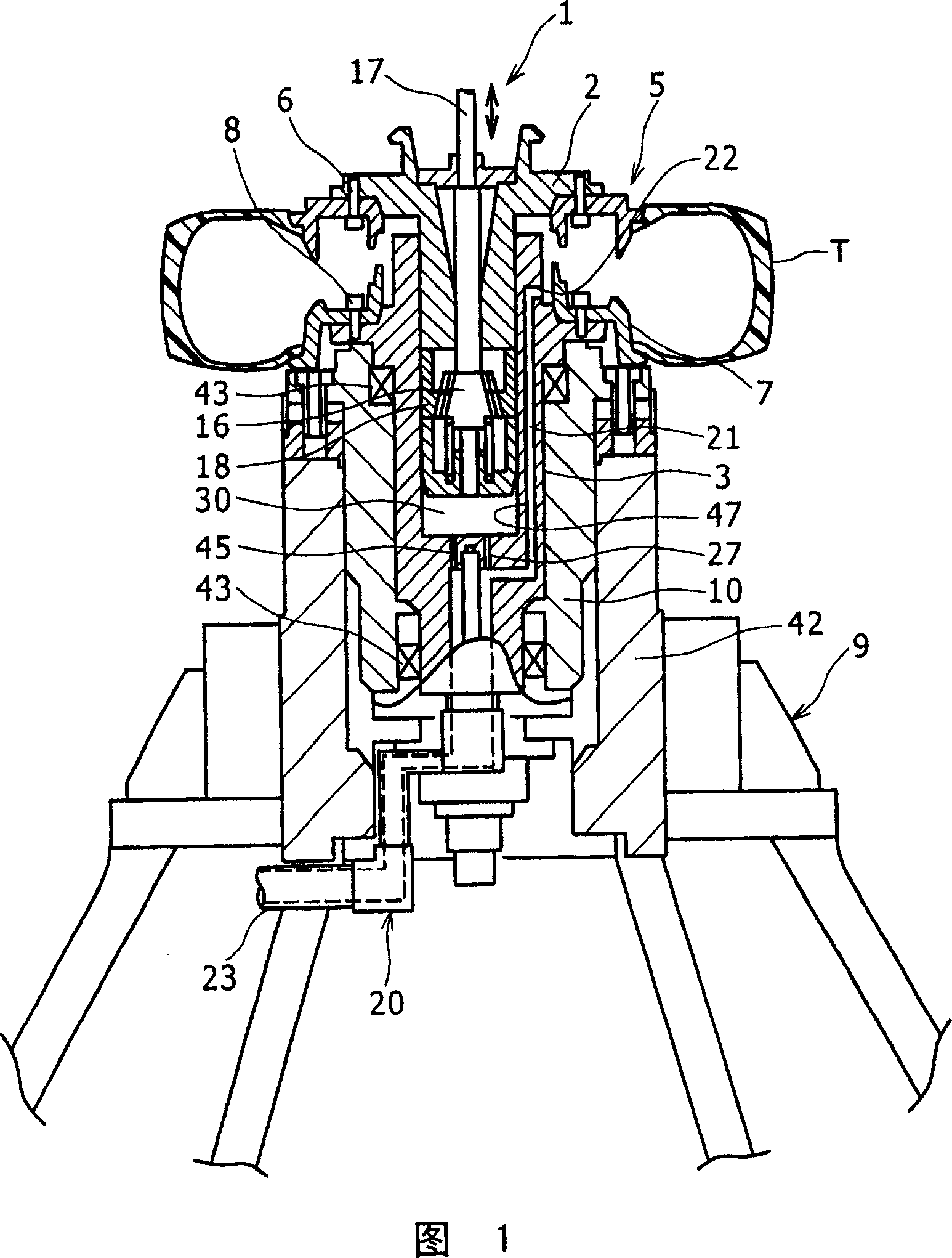

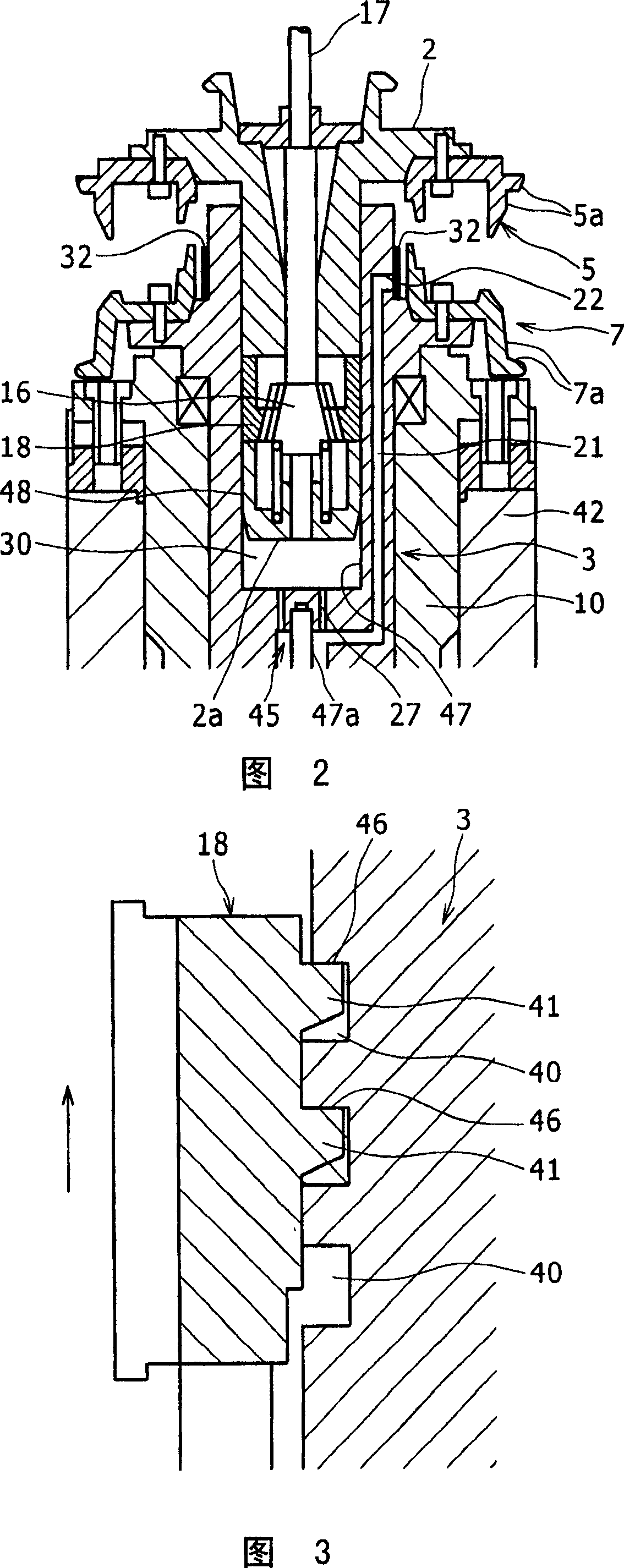

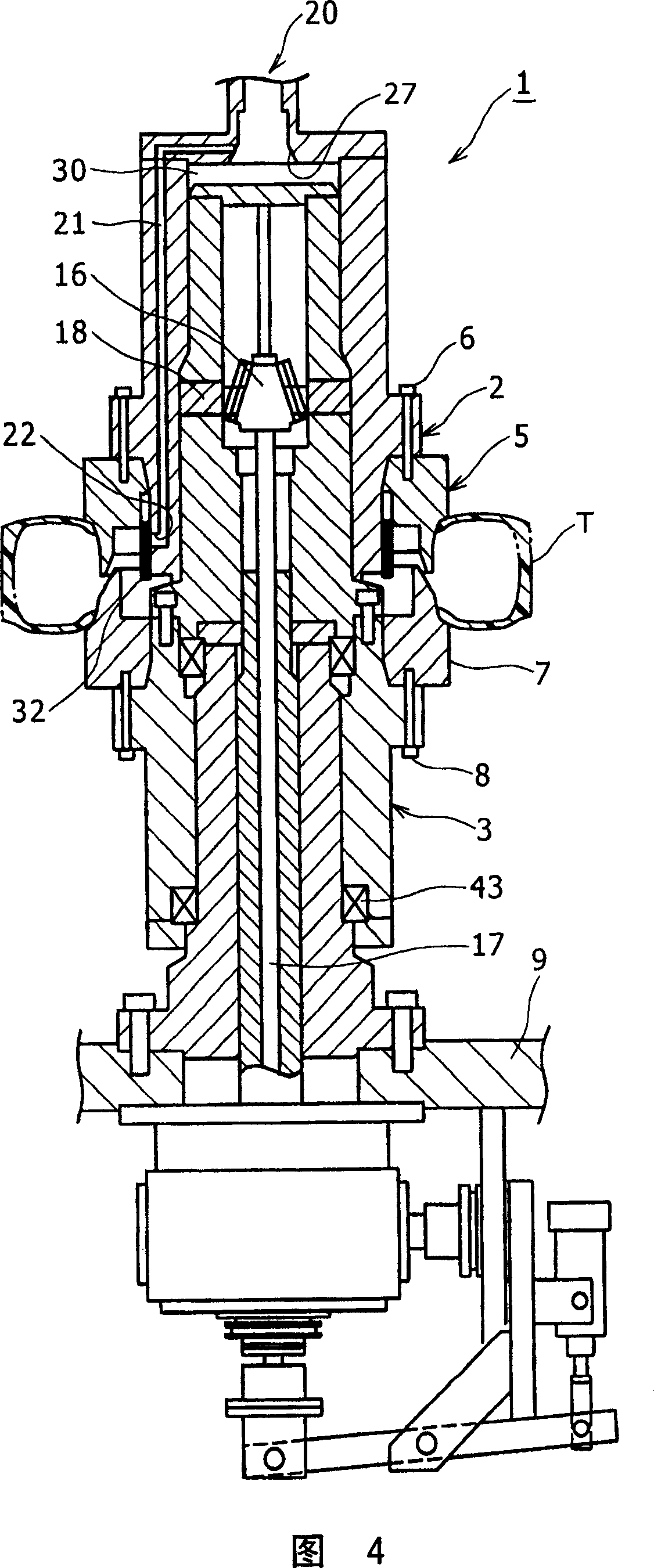

[0059] A description will now be given of a tire testing machine 1 according to a first embodiment of the present invention with reference to FIGS. 1-4.

[0060] 1-3 show a first embodiment of a tire testing machine 1 according to the invention.

[0061] The tire testing machine 1 comprises a tubular first mandrel 3 which is largely open at one end, a second mandrel 2 which has a cylindrical shape and is housed in the first mandrel 3 via the opening, and engages the second mandrel 2 so as to move radially from Lock 18 for extension and retraction of the second mandrel 2 . The first mandrel 3 and the second mandrel 2 are arranged vertically and move relative to each other, the first mandrel 3 is designed as a lower mandrel, and the second mandrel 2 is designed as an upper mandrel.

[0062] The upper rim 5 is fixed to the bottom end portion of the upper spindle 2 by bolts 6 , and the lower rim 7 is fixed to the top end portion of the lower spindle 3 by bolts 8 . The positions ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com