Insulating padding plate for precision machine and manufacture method for insulating padding plate

A technology of insulating pads and precision machinery, which is applied in the direction of manufacturing tools, stone processing tools, stone processing equipment, etc., can solve the problem of high cost of parts and achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

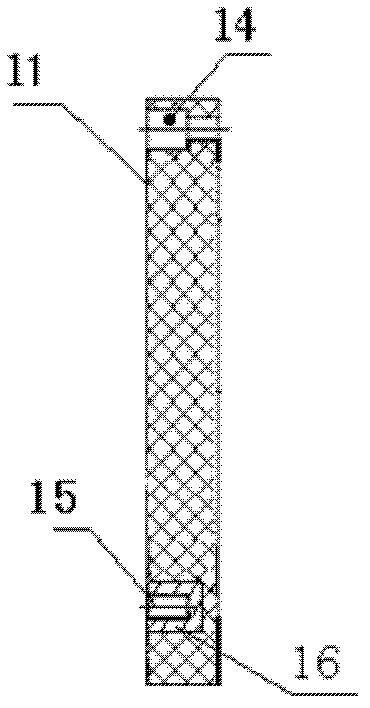

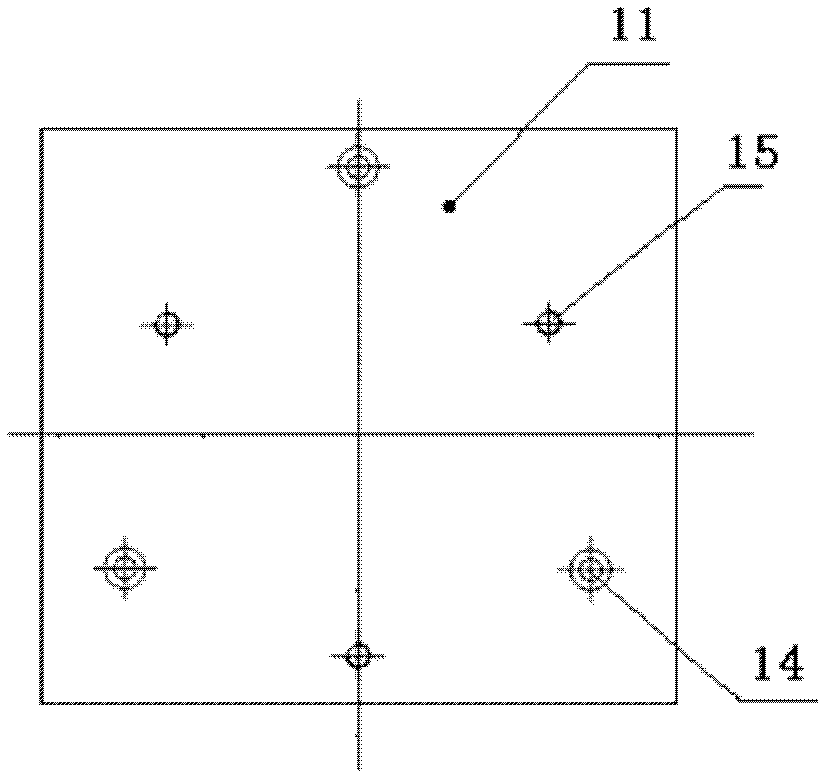

[0051] Such as figure 1 , 2 As shown, the main body 11 of the insulating backing plate for precision machinery of the present invention is a square shape, with three counterbores 14 for fixing the insulating backing plate to the lower parts, and three counterbores 14 for fixing the insulating backing plate to the upper parts. The connected blind hole 15 is bonded and fixed in the blind hole 15 with the aluminum column 16 processed with screw holes; the main body 11 of the insulating backing plate is made of marble or granite with a Platts hardness coefficient f greater than 8 but less than 10.

[0052] The manufacturing method of the above-mentioned insulating backing plate for precision machinery comprises the following steps:

[0053] 1. Saw marble or granite blocks into rough boards of required thickness by sawing processing method;

[0054] Two, process the raw plate obtained in step 1 into a square blank by sawing or chiseling;

[0055] 3. Process blind holes and count...

Embodiment 2

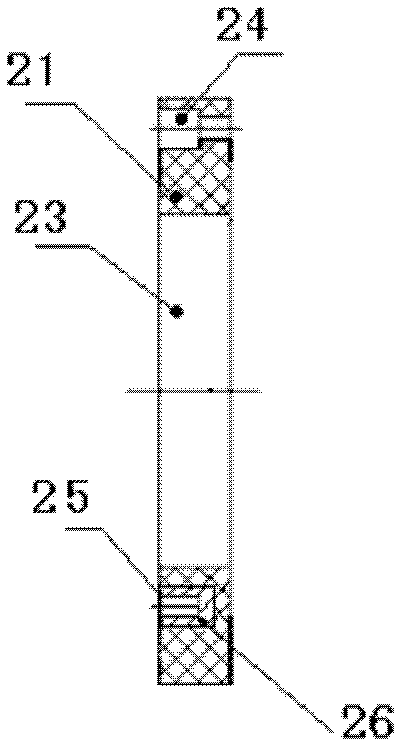

[0064] Such as image 3 , 4 As shown, the main body 21 of the insulating backing plate of the present invention is disc-shaped marble or granite with positioning holes 23, on which three blind holes 25 and three counterbores 24 are processed; Fixed in the blind hole 25; the flatness of the upper surface and the lower surface of the insulating backing plate main body 21 is less than 2 microns, and the parallelism between the upper surface and the lower surface of the insulating backing plate main body 21 is less than 3 microns.

[0065] The positioning hole 23 in the center of the insulating backing plate main body 21 is used for radial positioning between the insulating backing plate and the upper and lower parts, and the blind hole 25 and counterbore 24 are used for fixing between the insulating backing plate main body 21 and the upper and lower parts connect.

[0066] The manufacturing method of the above-mentioned insulating backing plate comprises the steps:

[0067] 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flatness | aaaaa | aaaaa |

| Flatness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com